ACH580 Installation, Operation and Maintenance Manual

87

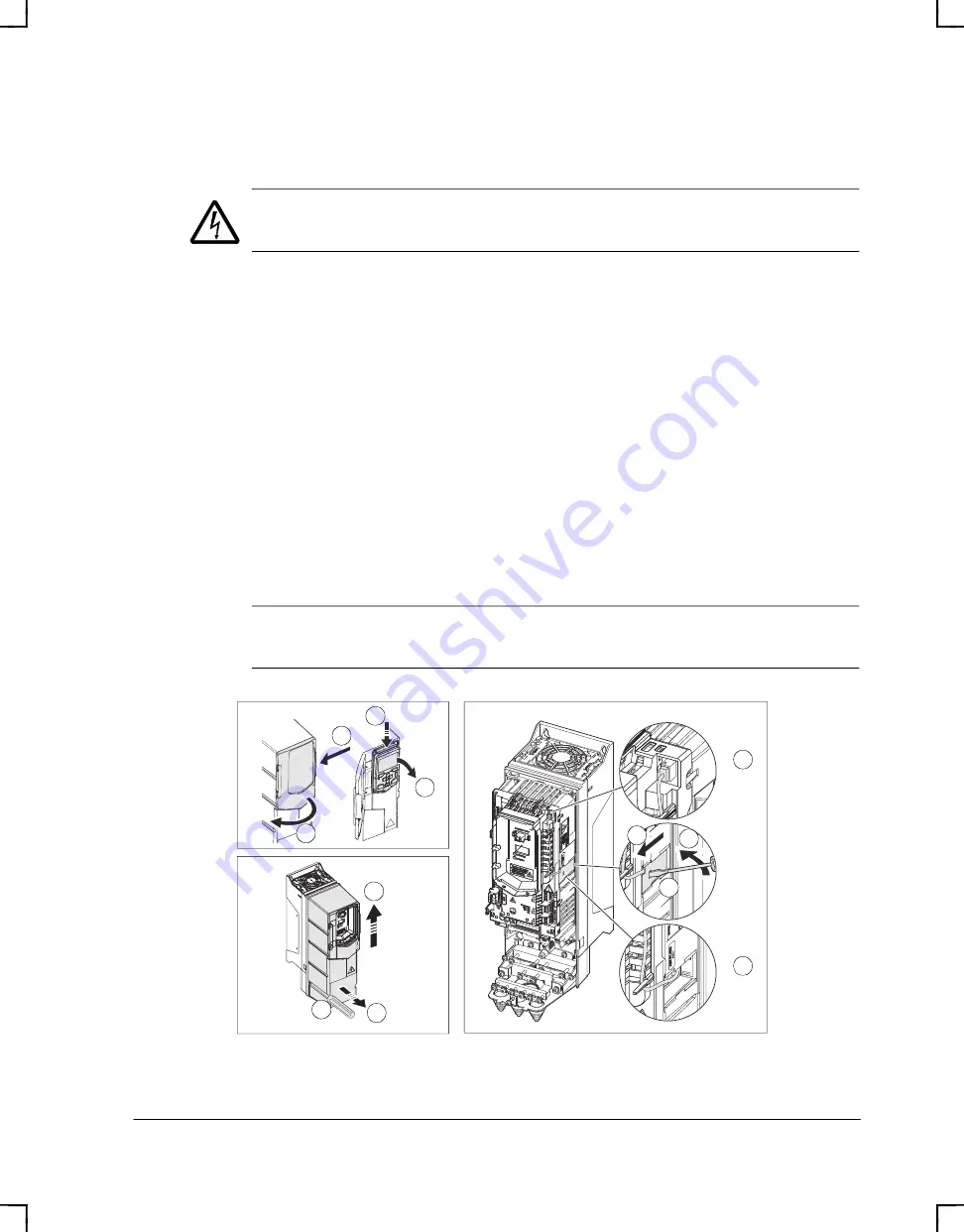

ACH580-01 Installation

IP55/UL (NEMA) Type 12 Frame Sizes R1…R2

To replace the fan:

WARNING!

. Ignoring the instructions can

cause physical injury or death, or damage to the equipment.

1. Stop the drive and disconnect it from the power line. Wait for 5 minutes and then

make sure by measuring that there is no voltage. See section

before you start the work.

2. Remove the control panel: Press the retaining clip of the IP55 panel cover (2a) and

open the cover (2b). Press the retaining clip of the control panel at the top (2c) and

pull it forward from the top edge (2d).

3. Remove the front cover: Loosen the retaining screws with a screwdriver (3a) and lift

the cover from the bottom outwards (3b) and then up (3c).

4. Unplug the fan power supply wires from the drive.

5. Remove the fingerguard: Insert a screwdriver into the hole of the fingerguard (5a),

bend the front edge of the fingerguard a little away from the drive frame with the

screwdriver (5b) and pull the fingerguard out of the groove (5c).

6. Pull off the fan.

7. Install the new fan assembly in reverse order. Route the wires round the pins.

Note:

Make sure that the arrow on the fan points to the same direction as the arrow

on the drive frame.

8. Restore power.

5c

5a

5b

2a

2c

2d

3c

3b

3a

4

7

2b

ACH580_Inst_Op_Maint_Rev G.book Page 87