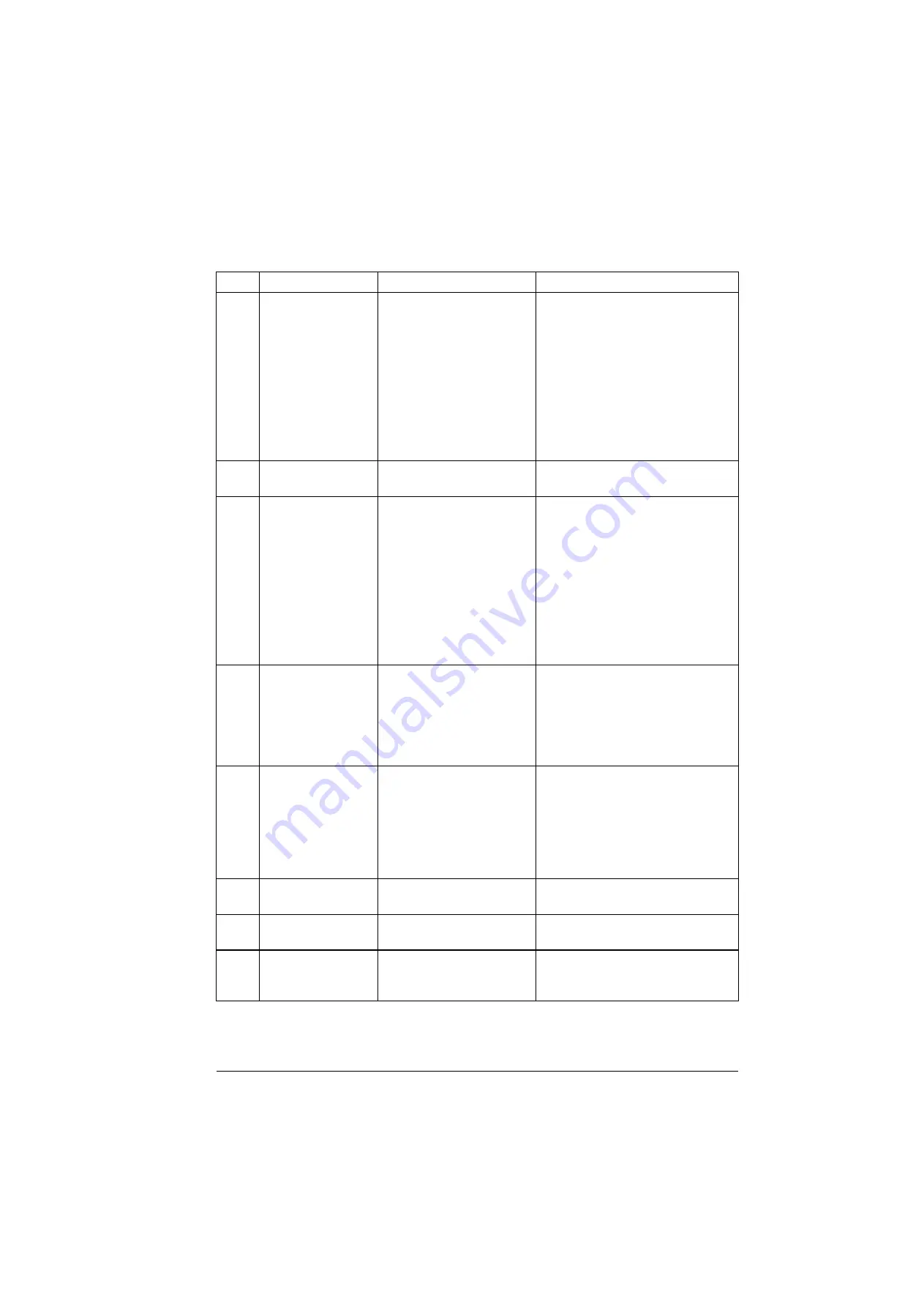

Fault tracing 307

0045

FIELDBUS COMM

Programmable

fault:

COMM

LOSS FUNC

Cyclical communication

between the drive and

fieldbus adapter module or

between PLC and fieldbus

adapter module is lost.

Check the status of fieldbus

communication. See the

appropriate fieldbus adapter

module

User’s manual

.

Check fieldbus parameter settings.

See parameter group

.

Check cable connections.

Check if the communication master

can communicate.

0046

FB MAPPING FILE Drive internal fault

Contact your local ABB

representative.

0047

MOTOR

OVERTEMP

Programmable

fault:

MOT

TEMP PROT

Measured motor

temperature has exceeded

the fault limit defined with

parameter

MOT

TEMP FLT LIM.

Check that the actual number of

sensors corresponds to the value

set with parameter

MOT

TEMP SOURCE.

Check motor ratings and load.

Let the motor cool down. Ensure

proper motor cooling: Check the

cooling fan, clean cooling surfaces,

etc.

Check the value of the fault limit.

0049

AI SUPERVISION

Programmable

fault:

AI

SUPERVISION

Analogue input AI1 or AI2

signal has reached the limit

defined with parameter

AI SUPERVIS ACT.

Check the analogue input AI1/2

source and connections.

Check analogue input AI1/2

minimum and maximum limit

settings, parameters

and

0050

ENCODER CABLE

Programmable

fault:

ENC

CABLE FAULT

Encoder cable fault

detected.

Check the cable between FEN-xx

interface and encoder. After any

modifications in cabling, re-

configure the interface by switching

the drive power off and on, or by

activating parameter

ENC

PAR REFRESH.

0055

TECH LIB

Resettable fault generated

by a technology library.

Refer to the documentation of the

technology library.

0056

TECH LIB

CRITICAL

Permanent fault generated

by a technology library.

Refer to the documentation of the

technology library.

0057

FORCED TRIP

Generic Drive

Communication Profile trip

command.

Check PLC status.

Code Fault

Cause

What to do

Summary of Contents for ACL30

Page 1: ...ABB high performance elevator drives User s manual ACL30 elevator drive ...

Page 4: ......

Page 20: ...20 Safety instructions ...

Page 34: ...34 Operation principle and hardware description ...

Page 42: ...42 Planning the cabinet installation ...

Page 60: ...60 Planning the electrical installation ...

Page 126: ...126 Using the control panel ...

Page 318: ...318 Maintenance ...

Page 334: ...334 The Safe torque off function ...

Page 338: ...338 Mains chokes ...

Page 342: ...342 EMC filters ...

Page 348: ...Dimension drawings 348 Frame size B D1 D2 W H1 H2 ...

Page 349: ...Dimension drawings 349 ...

Page 350: ...Dimension drawings 350 Frame size C D1 D2 H2 H1 W ...

Page 351: ...Dimension drawings 351 ...

Page 352: ...Dimension drawings 352 Frame size D ...

Page 354: ...354 Dimension drawings EMC filters JFI 0x ...

Page 356: ...356 Dimension drawings Brake resistors JBR xx ...

Page 358: ...358 Dimension drawings ...