WARNING!

Do not connect the +24 V AC cable to the control unit ground when the control

unit is powered using an external 24 V AC supply.

Start-up

■

Setting the parameters

1. Power up the drive.

2. If no warning is shown,

•

make sure that the value of both parameters

15.01 Extension module type

and

15.02 Detected extension module

is CMOD-01.

If warning A7AB

Extension I/O configuration failure

is shown,

•

make sure that the value of parameter

15.02

is CMOD-01.

•

set the parameter

15.01

value to CMOD-01.

You can now see the parameters of the extension module in parameter group

15

I/O extension module

.

3. Set the parameters of the extension module to applicable values.

Examples are given below.

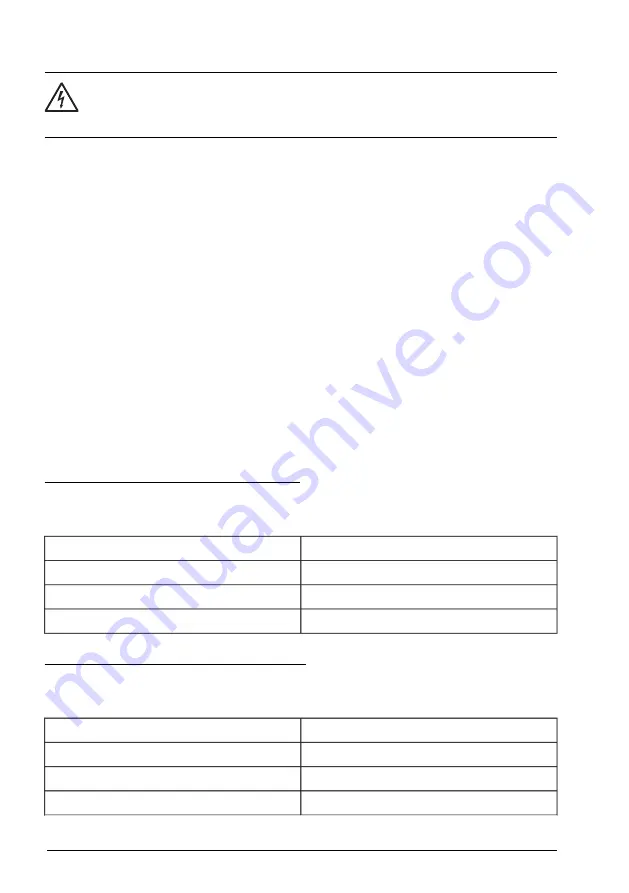

Parameter setting example for relay output

This example shows how make relay output RO4 of the extension module indicate the

reverse direction of rotation of the motor with a one-second delay.

Setting

Parameter

Reverse

15.07 RO4 source

1 s

15.08 RO4 ON delay

1 s

15.09 RO4 OFF delay

Parameter setting example for digital output

This example shows how to make digital output DO1 of the extension module indicate

the reverse direction of rotation of the motor with a one-second delay.

Setting

Parameter

Digital output

15.22 DO1 configuration

Reverse

15.23 DO1 source

1 s

15.24 DO1 ON delay

302 CMOD-01 multifunction extension module (external 24 V AC/DC and digital I/O)

Summary of Contents for ACQ580-07

Page 1: ... ABB DRIVES FOR WATER ACQ580 07 Hardware manual ...

Page 2: ......

Page 4: ......

Page 8: ...4 Update notice ...

Page 20: ...16 ...

Page 26: ...Measuring points of frames R6 to R9 are shown below PE L1 L2 L3 22 Safety instructions ...

Page 32: ...28 ...

Page 38: ...34 ...

Page 66: ...62 ...

Page 69: ...Mechanical installation 65 ...

Page 73: ... Mechanical installation 69 ...

Page 75: ...Declaration of Conformity Mechanical installation 71 ...

Page 108: ...104 ...

Page 133: ...Electrical installation 129 ...

Page 142: ...138 ...

Page 156: ...152 ...

Page 162: ...158 ...

Page 171: ...Maintenance 167 ...

Page 177: ...3 4 Maintenance 173 ...

Page 184: ...14 13 15 16 17 Remove the flange 180 Maintenance ...

Page 187: ...3 4 5 6 Remove the mounting plate Maintenance 183 ...

Page 189: ...8 Disconnect the drive module output busbars M12 70 N m 52 lbf ft 7 8 Maintenance 185 ...

Page 193: ...4 5 3 6 Remove the mounting plate Maintenance 189 ...

Page 195: ...8 Disconnect the drive module output busbars M12 70 N m 52 lbf ft 7 8 Maintenance 191 ...

Page 218: ...Frame R6 Input and motor cable terminal dimensions option F289 DET A 214 Technical data ...

Page 233: ...Frame R9 Input and motor cable terminal dimensions option F289 Technical data 229 ...

Page 257: ...13 Dimension drawings Example dimension drawings are shown below Dimension drawings 253 ...

Page 258: ...Frames R6 and R7 IP21 UL Type 1 254 Dimension drawings ...

Page 259: ...Frames R6 and R7 B054 IP42 UL Type 1 Filtered Dimension drawings 255 ...

Page 260: ...Frames R6 and R7 B055 IP54 UL Type 12 256 Dimension drawings ...

Page 261: ...Frames R6 and R7 H351 and H353 top entry and exit Dimension drawings 257 ...

Page 262: ...Frames R6 and R7 F289 258 Dimension drawings ...

Page 263: ...Frames R6 and R7 F289 H351 H353 Dimension drawings 259 ...

Page 264: ...Frames R8 and R9 IP21 UL Type 1 260 Dimension drawings ...

Page 265: ...Frames R8 and R9 B054 IP42 UL Type 1 Filtered Dimension drawings 261 ...

Page 266: ...Frames R8 and R9 B055 IP54 UL Type 12 262 Dimension drawings ...

Page 267: ...Frames R8 and R9 H351 and H353 top entry and exit Dimension drawings 263 ...

Page 268: ...Frames R8 and R9 F289 264 Dimension drawings ...

Page 269: ...Frames R8 and R9 F289 H351 H353 Dimension drawings 265 ...

Page 295: ... Declaration of conformity The Safe torque off function 291 ...

Page 296: ...292 ...

Page 302: ...298 ...

Page 309: ...CMOD 01 multifunction extension module external 24 V AC DC and digital I O 305 ...

Page 310: ...306 ...

Page 316: ...312 CMOD 02 multifunction extension module external 24 V AC DC and isolated PTC interface ...

Page 322: ...318 ...