•

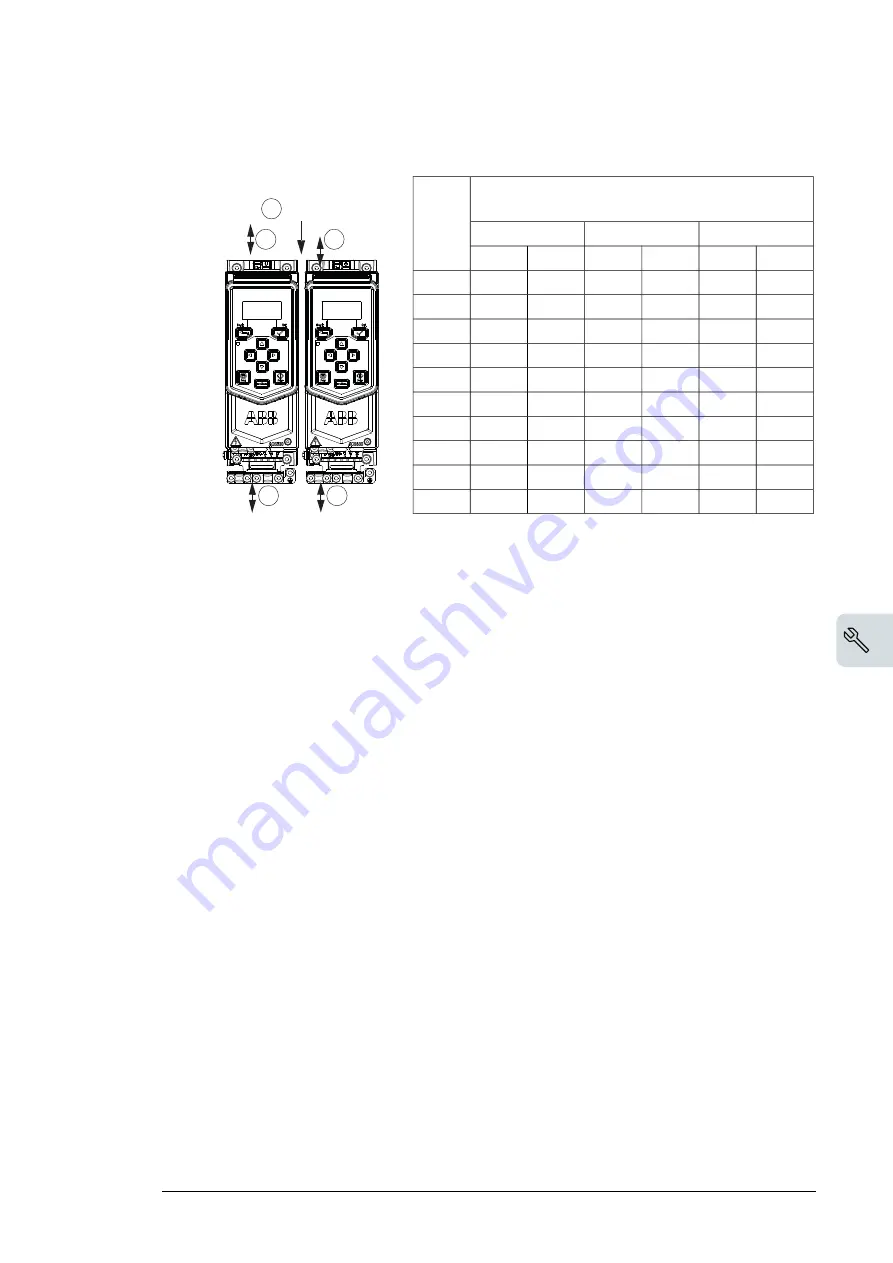

Vertically side by side

Vertical installation side by side -

Free space

Frame

Size

Between (c)

Below (b)

Above (a)

in

mm

in

mm

in

mm

0

0

3

75

3

75

R0

0

0

3

75

3

75

R1

0

0

3

75

3

75

R2

0

0

7.9

200

7.9

200

R3

0

0

7.9

200

7.9

200

R4

0

0

11.8

200

7.9

200

R5

0

0

11.8

300

7.9

200

R6

0

0

11.8

300

7.9

200

R7

0

0

11.8

300

7.9

200

R8

0

0

11.8

300

7.9

200

R8

40 Mechanical installation

Checking the installation site

The drive must be placed in a cabinet and installed on the wall. Drives of frame sizes

R0...R2 have two installation method as follows:

• Vertically alone

• Vertically side by side

a

b

c

Frame

Size

Vertical installation

Free space

Above (a)

Below (b)

Beside (c)

mm

in

mm

in

mm

in

R0

30

1.2

200

7.9

150

5.9

R1

30

1.2

200

7.9

150

5.9

R2

30

1.2

200

7.9

150

5.9

R3

53

2.1

200

7.9

150

5.9

R4

53

2.1

200

7.9

150

5.9

R6

155

6.1

300

11.8

150

5.9

R7

155

6.1

300

11.8

150

5.9

R8

155

6.1

300

11.8

150

5.9

.

Frame

size

Vertical installation side by side -

Free space

Above (a)

Below (b)

Between (c)

mm

in

mm

in

mm

in

R0

75

3

75

3

0

0

R1

75

3

75

3

0

0

R2

75

3

75

3

0

0

R3

200

7.9

200

7.9

0

0

R4

200

7.9

200

7.9

0

0

R5

200

7.9

200

11.8

0

0

R6

200

7.9

300

11.8

0

0

R7

200

7.9

300

11.8

0

0

R8

200

7.9

300

11.8

0

0

R8

200

7.9

300

11.8

0

0

3AXD10000561047.xls

a

b

a

b

c = 0

3AXD10000651180.xls A

Check the installation site according to the requirements below:

•

The installation site is sufficiently ventilated or cooled to remove heat from the drives.

See section

Thermal losses, cooling data and noise (page 121)

.

•

The operation conditions of the drive meet the specifications given in section

•

The wall is as close to vertical as possible, of non-flammable material and strong enough

to carry the weight of the drive, see section

.

•

The floor/material below the installation is non-flammable.

•

There is enough free space above and below the drive to enable cooling air flow, service

and maintenance, See the required free space tables for each of the different mounting

alignments in

Checking the installation site (page 40)

(or

Required tools

To install the drive mechanically, you need the following tools:

•

Drill with suitable bits.

•

Screwdriver and/or wrench with a set of suitable bits (as appropriate for the installation

hardware used).

•

Tape measure, if you are not using the provided mounting template.

Moving the drive

Frames R5…R8: Move the transport package by pallet truck to the installation site.

Mechanical installation 41

10

Summary of Contents for ACQ80-04 Series

Page 1: ...ABB DRIVES FOR WATER ACQ80 04 drives 0 75 to 160 kW 1 0 to 215 hp Hardware manual...

Page 2: ......

Page 4: ......

Page 18: ...18...

Page 24: ...24...

Page 38: ...38...

Page 50: ...50...

Page 64: ...64...

Page 98: ...98...

Page 110: ...110...

Page 140: ...Frame R3 IP20 140 Dimension drawings...

Page 146: ...146...

Page 162: ...162...

Page 168: ......