3. Connect the motor cable as follows:

•

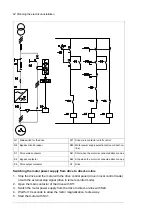

Ground the shield 360 degrees by tightening the clamp of the power cable grounding

shelf onto the stripped part of the cable (3a).

•

Connect the twisted shield of the cable to the grounding terminal (3b).

•

Connect the phase conductors of the cable to the terminals of T1/U, T2/V and T3/W.

Electrical installation 79

3. Connect the motor cable as follows:

•

Ground the shield 360 degrees by tightening the clamp of the power cable

grounding shelf onto the stripped part of the cable (3a).

•

Connect the twisted shield of the cable to the grounding terminal (3b).

•

Connect the phase conductors of the cable to the terminals of T1/U, T2/V and

T3/W.

•

Tighten the screws to the torque given below.

Input power cable

4. Prepare the ends of the cable as illustrated in the figure.

Note:

The bare shield will be grounded 360 degrees. Mark the pigtail made from

the shield as a PE conductor with yellow-and-green color.

Frame size

R0

…

R1

R2

N·m

lbf·ft

N·m

lbf·ft

T1/U. T2/V. T3/W

0.5…0.6

0.4

1.2…1.5 0.9…1.1

3b

3c

3a

PE

PE

•

Tighten the screws to the torque given below.

R2

R0…R1

Frame size

lbf·ft

N·m

lbf·ft

N·m

0.9…1.1

1.2…1.5

0.4

0.5…0.6

T1/U. T2/V. T3/W

Input power cable

4. Prepare the ends of the cable as illustrated in the figure.

Note:

The bare shield will be grounded 360 degrees. Mark the pigtail made from the shield as a

PE conductor with yellow-and-green color

PE

PE

5. Connect the input power cable as follows:

•

Connect the twisted shield of the cable to the grounding terminal (5a).

Electrical installation 73

11

Summary of Contents for ACQ80-04 Series

Page 1: ...ABB DRIVES FOR WATER ACQ80 04 drives 0 75 to 160 kW 1 0 to 215 hp Hardware manual...

Page 2: ......

Page 4: ......

Page 18: ...18...

Page 24: ...24...

Page 38: ...38...

Page 50: ...50...

Page 64: ...64...

Page 98: ...98...

Page 110: ...110...

Page 140: ...Frame R3 IP20 140 Dimension drawings...

Page 146: ...146...

Page 162: ...162...

Page 168: ......