•

Connect the phase conductors of the cable to the L1, L2 and L3 terminals.

80 Electrical installation

5. Connect the input power cable as follows:

•

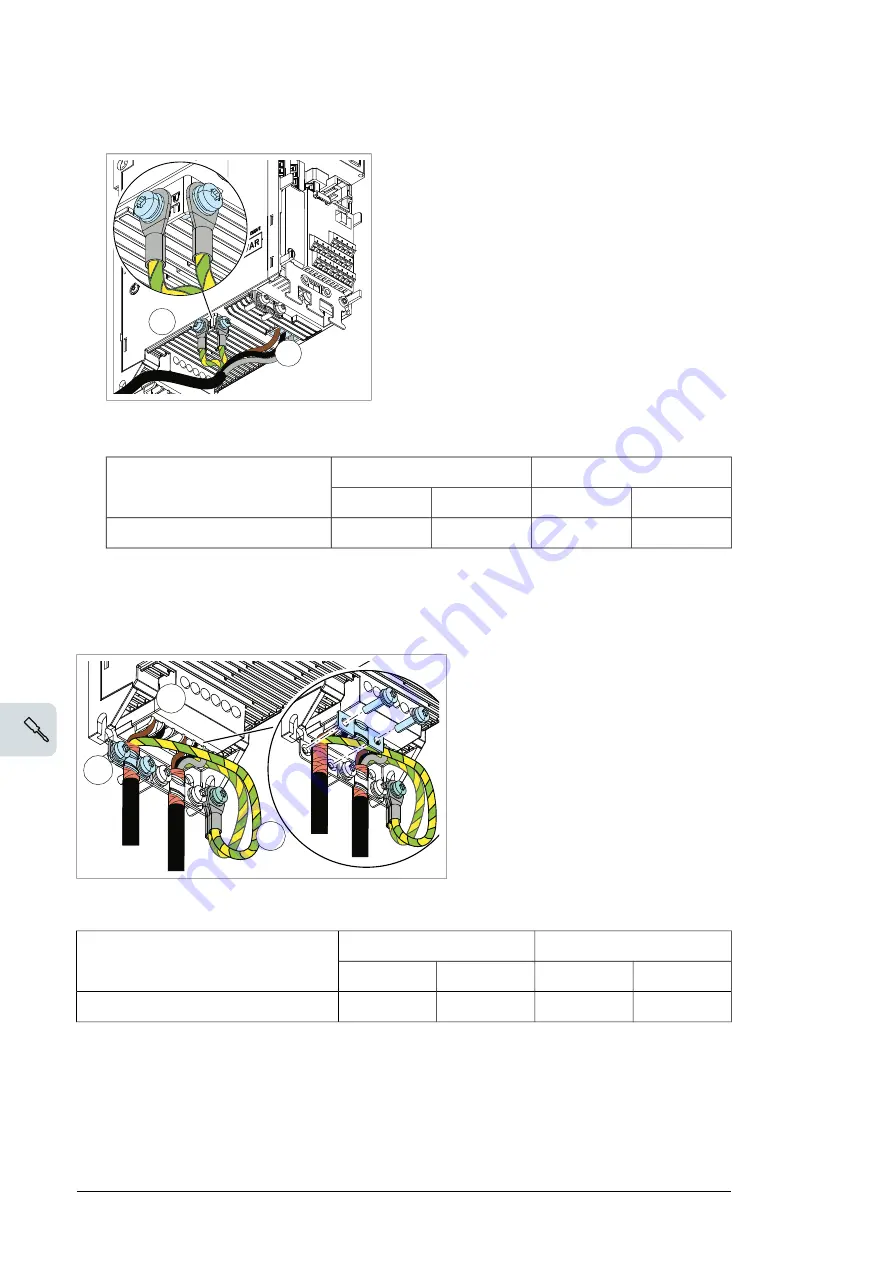

Connect the twisted shield of the cable to the grounding terminal (5a).

•

Connect the phase conductors of the cable to the L1, L2 and L3 terminals.

•

Tighten the screws to the torque given below:

6. Connect the braking resistor cable as the motor cable in step 4.

7. Ground the shield 360 degrees (6a).

8. Connect the twisted shield to the grounding terminal (6b) and the conductors to

the R+ and R- terminals (6c).

9. Tighten the screws to the torque given below.

Frame size

R0

…

R1

R2

N·m

lbf·ft

N·m

lbf·ft

L1. L2. L3

0.5…0.6

0.4

1.2…1.5 0.9…1.1

Frame size

R0

…

R1

R2

N·m

lbf·ft

N·m

lbf·ft

R+. R-

0.5…0.6

0.4

1.2…1.5 0.9…1.1

5b

5a

6a

6b

6c

•

Tighten the screws to the torque given below:

R2

R0…R1

Frame size

lbf·ft

N·m

lbf·ft

N·m

0.9…1.1

1.2…1.5

0.4

0.5…0.6

L1, L2, L3

7. Ground the shield 360 degrees (6a).

8. Connect the twisted shield to the grounding terminal (6b) and the PV input terminals to

UDC+ and UDC- (6c).

80 Electrical installation

5. Connect the input power cable as follows:

•

Connect the twisted shield of the cable to the grounding terminal (5a).

•

Connect the phase conductors of the cable to the L1, L2 and L3 terminals.

•

Tighten the screws to the torque given below:

6. Connect the braking resistor cable as the motor cable in step 4.

7. Ground the shield 360 degrees (6a).

8. Connect the twisted shield to the grounding terminal (6b) and the conductors to

the R+ and R- terminals (6c).

9. Tighten the screws to the torque given below.

Frame size

R0

…

R1

R2

N·m

lbf·ft

N·m

lbf·ft

L1. L2. L3

0.5…0.6

0.4

1.2…1.5 0.9…1.1

Frame size

R0

…

R1

R2

N·m

lbf·ft

N·m

lbf·ft

R+. R-

0.5…0.6

0.4

1.2…1.5 0.9…1.1

5b

5a

6a

6b

6c

9. Tighten the screws to the torque given below.

R2

R0…R1

Frame size

lbf·ft

N·m

lbf·ft

N·m

0.9…1.1

1.2…1.5

0.4

0.5…0.6

UDC+, UDC-

Finalization

10. Ground the motor cable shield at the motor end. For minimum radio frequency

interference, ground the motor cable shield 360 degrees at the lead-through of the motor

terminal box

74 Electrical installation

Summary of Contents for ACQ80-04 Series

Page 1: ...ABB DRIVES FOR WATER ACQ80 04 drives 0 75 to 160 kW 1 0 to 215 hp Hardware manual...

Page 2: ......

Page 4: ......

Page 18: ...18...

Page 24: ...24...

Page 38: ...38...

Page 50: ...50...

Page 64: ...64...

Page 98: ...98...

Page 110: ...110...

Page 140: ...Frame R3 IP20 140 Dimension drawings...

Page 146: ...146...

Page 162: ...162...

Page 168: ......