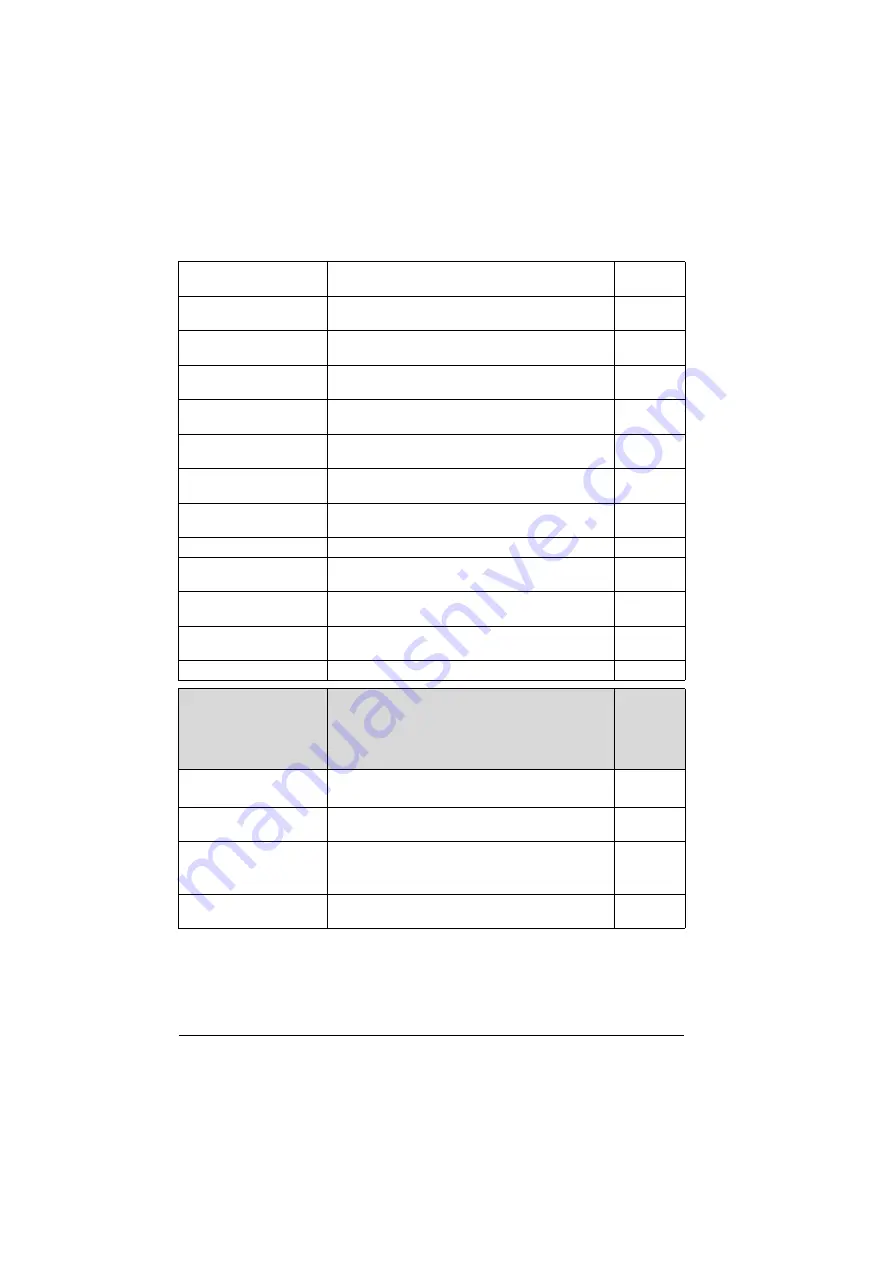

190 Parameters

Percentage of samples recorded by amplitude

logger 2 that fall between 60 and 70%.

0.00%

0.00…100.00%

Amplitude logger 2 samples between 60 and

70%.

1 = 1%

Percentage of samples recorded by amplitude

logger 2 that fall between 70 and 80%.

0.00%

0.00…100.00%

Amplitude logger 2 samples between 70 and

80%.

1 = 1%

Percentage of samples recorded by amplitude

logger 2 that fall between 80 and 90%.

0.00%

0.00…100.00%

Amplitude logger 2 samples between 80 and

90%.

1 = 1%

Percentage of samples recorded by amplitude

logger 2 that exceed 90%.

0.00%

0.00…100.00%

Amplitude logger 2 samples over 90%.

1 = 1%

The date on which amplitude logger 2 was last

reset.

01/01/198

0

1/1/1980...6/5/

2159

Last reset date of amplitude logger 2.

-

The time at which amplitude logger 2 was last

reset.

00:00:00

-

Last reset time of amplitude logger 2.

-

40

Parameter values for process PID control.

The drive output can be controlled by the process

PID. When the process PID control is enabled, the

drive controls the process feedback to the

reference value.

Shows output of the process PID controller.

This parameter is read-only.

-

-200000.00...

200000.00

Process PID controller output.

1 = 1

Shows value of process feedback after source

selection, mathematical function and filtering.

This parameter is read-only.

-

-200000.00...

200000.00

Process feedback.

1 = 1

No.

Name/Value

Description

Def/

FbEq16

Summary of Contents for ACQ80

Page 1: ... ABB DRIVES FOR WATER ACQ80 standard program control Firmware manual ...

Page 2: ... Related documents are listed on page 13 ...

Page 4: ......

Page 10: ...10 Table of contents ...

Page 32: ...32 Startup control with I O and ID run ...

Page 34: ...34 Using the control panel ...

Page 74: ...74 Program features ...

Page 78: ...78 Control macros ...

Page 380: ...380 Fieldbus control through a fieldbus adapter ...

Page 384: ...384 Parameterization with Drive Composer ...

Page 388: ...388 Parameterization with Automation builder drive manager ...