ACS 160 User’s Manual

45

Parameter Guide

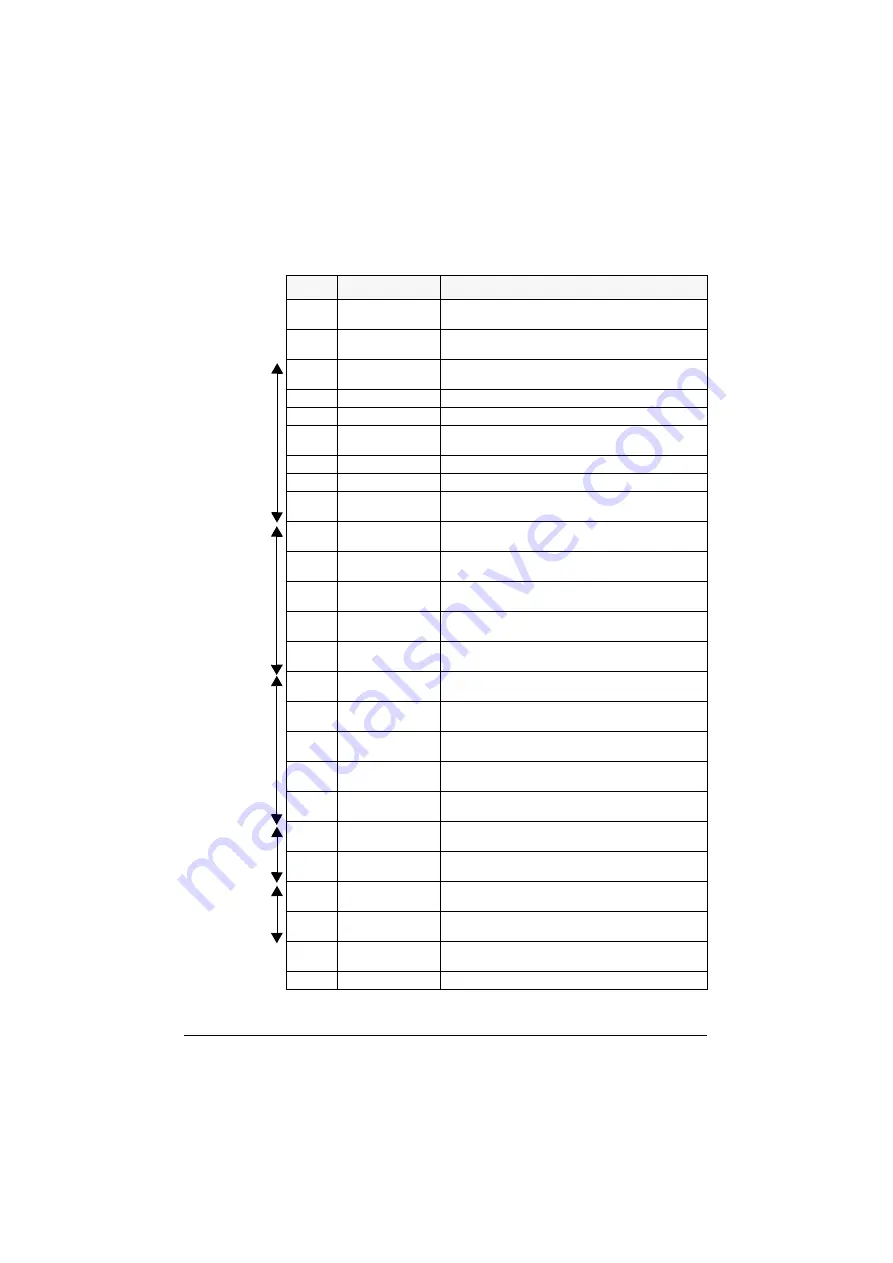

Group

Name

Description

99

Start-up Data

Parameter settings for setting up the drive and for

entering motor information.

01

Operating Data

Read only parameters for drive operation data, including

actual signals and fault memories.

10

Command Inputs

Parameter settings for start, stop and direction

commands.

11

Reference Select

Parameter settings for reference commands / locations.

12

Constant Speeds

Parameter settings for constant speed value input.

13

Analogue Input

Parameter settings for max, min and filter for the

analogue input.

14

Relay Outputs

Parameter settings for relay output characteristics.

15

Analogue Outputs

Parameter settings for analogue output.

16

System Controls

Parameter settings for enabling/disabling parameter

access, run enable etc.

20

Limits

Parameter settings for limiting operating features and

overvoltage control.

21

Start/Stop

Parameter settings for selecting start and stop modes,

flying start, torque boosting, DC hold, ramp coast etc.

22

Acc/Decel

Parameter settings for defining the two acceleration/

deceleration ramp pairs.

25

Critical Freq

Parameter settings for setting critical freq to avoid

resonance problems.

26

Motor Control

Parameter settings for selecting motor control features,

like IR compensation and low noise u/f ratio.

30

Fault Functions

Parameter settings for configuring desired response to

certain abnormal external conditions.

31

Automatic Reset

Parameter settings for automatically resetting some

faults.

32

Supervision

Parameter settings for any 2 parameters of group 01 to

be supervised in co-operation with relays.

33

Information

Read only parameters for information about the

software version and production date.

34

Process Variables

Parameter settings for creating custom process

variables.

40

PID Control

Parameter settings for the first set of PID Control

parameters.

41

PID Control (2)

Parameter settings for the second set of PID Control

parameters.

51

Ext Comm Module

Parameter settings for external fieldbus communication

modules.

52

Standard Modbus

Parameter settings for standard Modbus (serial

communication).

54

Braking

Parameter settings for selecting additional braking

features.

81

Positioning

Parameter settings for positioning applications.

Set-up

Operating

Configuration

Performance

Information

Supervision

PID

Fieldbus

Braking

Positioning

Summary of Contents for ACS 160

Page 2: ......

Page 4: ......

Page 10: ...viii ACS 160 User s Manual ...

Page 12: ...2 ACS 160 User s Manual ...

Page 32: ...22 ACS 160 User s Manual ...

Page 42: ...32 ACS 160 User s Manual ...

Page 56: ...46 ACS 160 User s Manual ...

Page 116: ...106 ACS 160 User s Manual ...

Page 122: ...112 ACS 160 User s Manual ...

Page 126: ...116 ACS 160 User s Manual ...

Page 136: ...126 ACS 160 User s Manual ...

Page 137: ......