ACS 400 User’s Manual

59

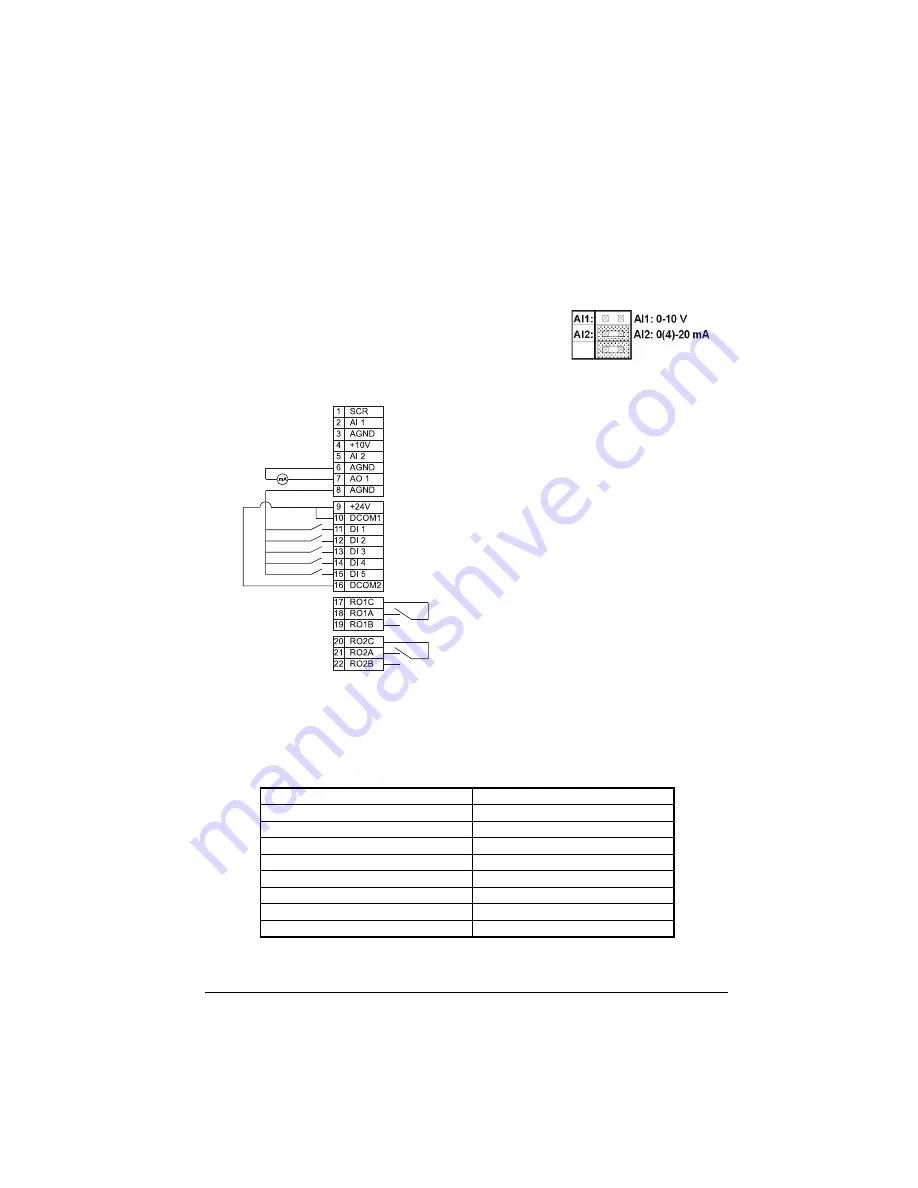

Application Macro Motor Potentiometer

This macro provides a cost-effective interface for PLCs that vary the speed of the drive using only

digital signals.

The value of parameter 9902 is 4 (

MOTOR

POT

).

*Note!

•

If both DI 3 and DI 4 are active or inactive, reference is kept stable.

•

Reference is stored during stop or power down condition.

•

Analog reference is not followed when motor potentiometer is selected.

Motor potentiometer parameter values:

Input signals

Output signals

Jumper Setting

• Start, stop and direction

(DI1,2)

• An. output AO: Frequency

• Reference up (DI3)

• Relay output 1: Fault

• Reference down (DI4)

• Relay output 2: Running

• Preset speed selection (DI5)

1001

EXT

1

COMMANDS

2 (

DI

1,2)

1402

RELAY

OUTPUT

2

2 (

RUN

)

1002

EXT

2

COMMANDS

0 (

NOT

SEL

)

1503

AO

CONTENT

MAX

60 Hz

1003

DIRECTION

3 (

REQUEST

)

1601

RUN

ENABLE

0 (

NOT

SEL

)

1102

EXT

1/

EXT

2

SEL

6 (

EXT

1)

1604

FAULT

RESET

SEL

0 (

KEYPAD

)

1103

EXT

REF

1

SELECT

6 (

DI

3

U

,4

D

)

2008

MAXIMUM

FREQ

60 Hz

1105

EXT

REF

1

MAX

60 Hz

2105

PREMAGN

SEL

0 (

NOT

SEL

)

1106

EXT

REF

2

SELECT

0 (

KEYPAD

)

2201

ACC

/

DEC

1/2

SEL

0 (

NOT

SEL

)

1201

CONST

SPEED

SEL

5 (

DI

5)

4001

PID

GAIN

1.0

1401

RELAY

OUTPUT

1

3 (

FAULT

(-1))

4002

PID

INTEG

TIME

60 s

External Reference 1: 0...10 V

Reference voltage 10 VDC

Not used

Output frequency 0...20 mA <=> 0...50 Hz

+24 VDC

Start/Stop: Activate to start.

Forward/Reverse: Activate to reverse rotation direction

Reference up: Activate to increase reference*

Reference down: Activate to decrease reference*

Constant speed 1

Relay output 1, programmable

Default operation: Fault => 17 connected to 18

Relay output 2, programmable

Default operation: Running => 20 connected to 22

http://nicontrols.com

Summary of Contents for ACS 400

Page 3: ...http nicontrols com ...

Page 5: ...http nicontrols com ...

Page 7: ...iv ACS 400 User s Manual http nicontrols com ...

Page 45: ...34 ACS 400 User s Manual http nicontrols com ...

Page 52: ...ACS 400 User s Manual 41 Motor Will Not Run http nicontrols com ...

Page 53: ...42 ACS 400 User s Manual Motor Stalls during Acceleration http nicontrols com ...

Page 54: ...ACS 400 User s Manual 43 Overvoltage Fault Indication http nicontrols com ...

Page 55: ...44 ACS 400 User s Manual Overcurrent Fault Indication http nicontrols com ...

Page 56: ...ACS 400 User s Manual 45 Overload Fault Indication http nicontrols com ...

Page 57: ...46 ACS 400 User s Manual Undervoltage Fault Indication http nicontrols com ...

Page 58: ...ACS 400 User s Manual 47 External Fault Indication http nicontrols com ...

Page 59: ...48 ACS 400 User s Manual No Operator Display http nicontrols com ...

Page 75: ...64 ACS 400 User s Manual http nicontrols com ...

Page 161: ...150 ACS 400 User s Manual http nicontrols com ...

Page 167: ...156 ACS 400 User s Manual http nicontrols com ...

Page 177: ...166 ACS 400 User s Manual http nicontrols com ...

Page 179: ...168 ACS 400 User s Manual ACS 400 NEMA Type 1 Enclosure R2 Frame Size http nicontrols com ...

Page 180: ...ACS 400 User s Manual 169 ACS 400 NEMA Type 1 Enclosure R3 Frame Size http nicontrols com ...

Page 181: ...170 ACS 400 User s Manual ACS 400 NEMA Type 1 Enclosure R4 Frame Size http nicontrols com ...

Page 182: ...ACS 400 User s Manual 171 ACS 400 NEMA Type 12 4 Enclosure R1 Frame Size http nicontrols com ...

Page 183: ...172 ACS 400 User s Manual ACS 400 NEMA 12 4 Enclosure R2 Frame Size http nicontrols com ...

Page 184: ...ACS 400 User s Manual 173 ACS 400 NEMA Type 12 4 R3 Frame Size http nicontrols com ...

Page 185: ...174 ACS 400 User s Manual ACS 400 NEMA Type 12 4 R4 Frame Size http nicontrols com ...

Page 186: ...http nicontrols com ...