15

4.

Mechanical Installation

4.1.

General

The ACS255 should be mounted in a vertical position only, on a flat, flame resistant, vibration free mounting using the integral

mounting holes or DIN Rail clip (Size P2 only).

The ACS255 must be installed in a pollution degree 1 or 2 environment only.

Do not mount flammable material close to the ACS255

Ensure that the minimum cooling air gaps, as detailed in section 4.5 and 4.7 are left clear.

Ensure that the ambient temperature range does not exceed the permissible limits for the ACS255 are given on page 60.

Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the ACS255.

4.2.

Before Installation

Carefully Unpack the ACS255 and check for any signs of damage. Notify the shipper immediately if any exist.

Check the drive rating label to ensure it is of the correct type and power requirements for the application.

To prevent accidental damage always store the ACS255 in its original box until required. Storage should be clean and dry and within

the temperature range –40°C to +60°C.

4.3.

UL Compliant Installation

Note the following for UL-compliant installation:

For an up to date list of UL compliant products, please refer to UL listing NMMS.E211945.

The drive can be operated within an ambient temperature range as stated in section 11.1.

For IP20 units, installation is required in a pollution degree 1 environment.

For IP66 units, installation in a pollution degree 2 environment is permissible.

UL Listed ring terminals / lugs must be used for all bus bar and grounding connections.

4.4.

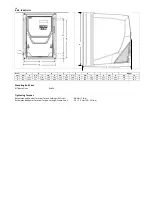

Mechanical dimensions and weights

4.4.1.

IP20 Units

Drive

Size

A

B

C

D

E

F

G

H

I

J

Weight

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Kg

Ib

2

221

8.70

207

8.15

137

5.39

209

8.23

5.3

0.21

185

7.28

112

4.41

63

2.48

5.5

0.22

10

0.39

1.8

4

3

261

10.28

246

9.69

-

-

247

9.72

6

0.24

205

8.07

131

5.16

80

3.15

5.5

0.22

10

0.39

3.5

7.7

Mounting Bolts

All Frame Sizes :

4 x M4

Tightening Torques

Recommended Control Terminal Torque Settings :

All Sizes : 0.8 Nm (7 lb-in)

Recommended Power Terminal Torque Settings : All Sizes : 1 Nm (8.85 lb-in)