24 Actual signals and parameters

0.0…1400.0 Hz Frequency

1 = 0.1 Hz

2615 USER

DEFINED F3

Defines the third frequency point of the custom U/f curve.

25.0 Hz

0.0…1400.0 Hz Frequency

1 = 0.1 Hz

2617 USER

DEFINED F4

Defines the fourth frequency point of the custom U/f curve. 40.0 Hz

0.0…1400.0 Hz Frequency

1 = 0.1 Hz

30 FAULT

FUNCTIONS

Programmable protection functions

3029 FAULT RAMP

STOP

Selects how the drive reacts when the drive trips to fault

excepting Hardware critical faults (OVERCURRENT, DC

OVERVOLT and SHORT CIRC), SAFE TORQUE OFF,

STO1 LOST and STO2 LOST faults.

1

DISABLE

Drive makes coast stop when drive trips fault.

0

ENABLE

Drive makes emergency ramp stop when drive trips fault

using the emergency ramp stop deceleration time (par.

22.08).

1

40 PROCESS PID

SET 1

Process PID (PID1) control parameter set 1.

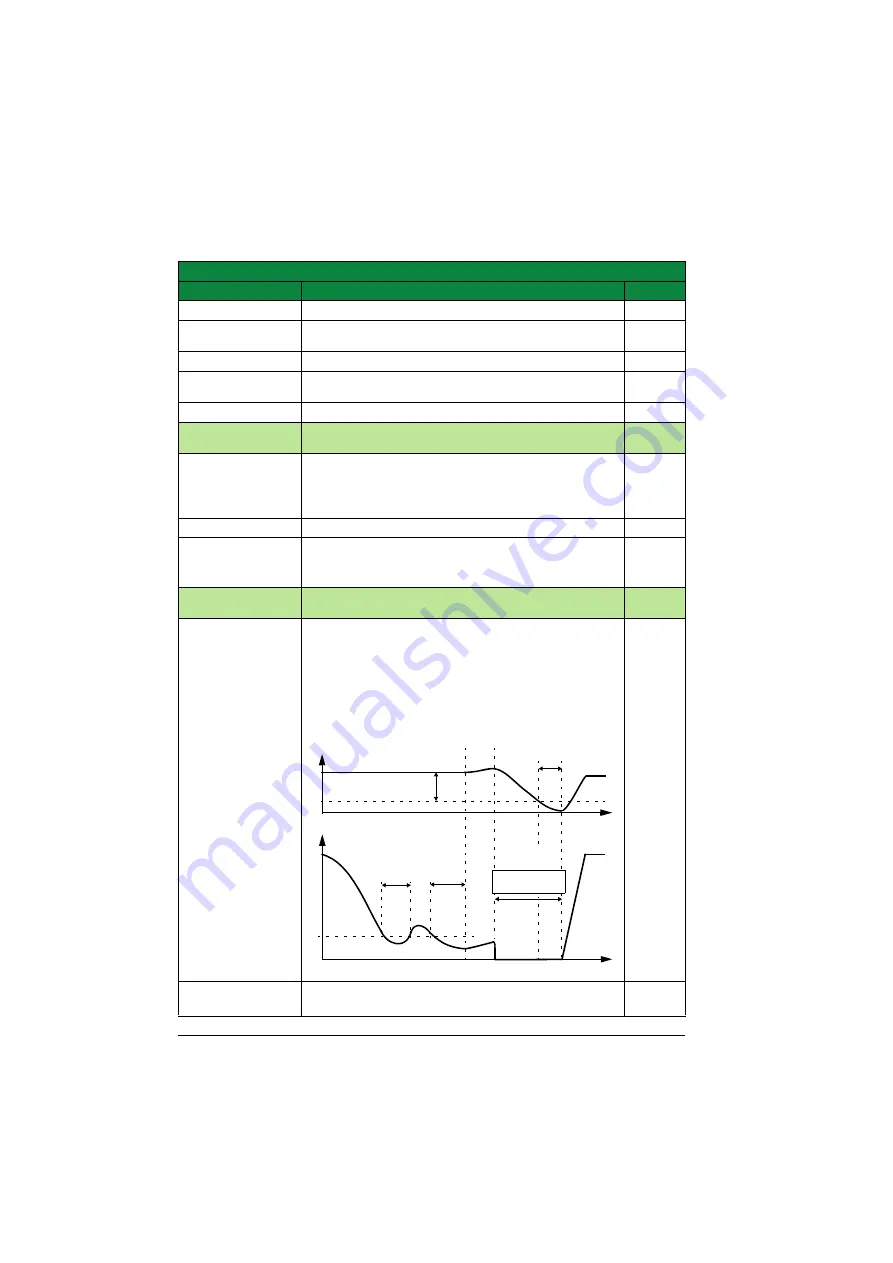

4023 PID SLEEP

LEVEL

Defines the start limit for the sleep function. If the motor

speed is below a set level (

) longer than the sleep

delay (4024), the drive shifts to the sleeping mode: The

motor is stopped and the control panel shows alarm

message PID SLEEP (2018).

Parameter 4022 SLEEP SELECTION must be set to

INTERNAL.

0.0 Hz /

0 rpm

0.0…1400.0 Hz

/ 0…32000 rpm

Sleep start level

1 = 0.1 Hz

1 rpm

All parameters

No.

Name/Value

Description

Def/FbEq

Wake-up level

deviation (

4025

)

t

<

t

sd

PID output level

PID process feedback

Stop

t

sd

= Sleep delay

(

4024

)

Sleep level

Start

Wake-up delay

(

4026

)

t

sd

t

Control

panel:

PID SLEEP

t

t

PID ref