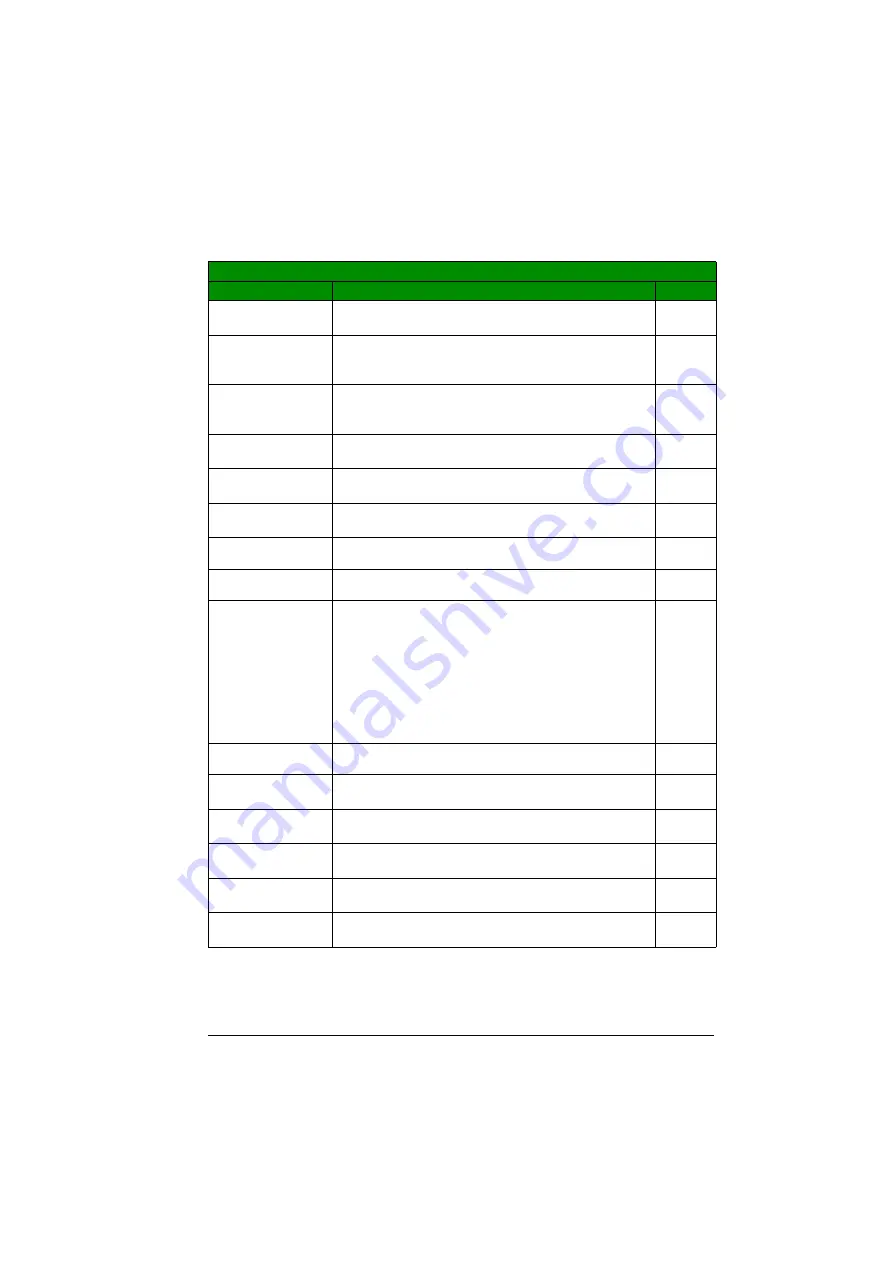

Actual signals and parameters 185

0144 DRIVE ON

TIME LO

Drive control board power-on time in 2 second ticks (30

ticks = 60 seconds). Counter cannot be reset.

1 = 2 s

0145 MOTOR TEMP Measured motor temperature. Unit depends on the sensor

parameters.

1 = 1

0146 MECH ANGLE Calculated mechanical angle. 1 = 5001 PULSE NR. The

signal indicates the angle as a percentage of the number of

pulses per revolution.

1 = 1

0147 MECH REVS

Mechanical revolutions, ie, the motor shaft revolutions

calculated by the encoder. Overflow is not prevented.

1 = 1

0148 Z PLS

DETECTED

Encoder zero pulse detector. 0 = NOT DETECTED, 1 =

DETECTED.

1 = 1

0150 CB TEMP

Temperature of the drive control board in degrees Celsius

(0.0…150.0 °C).

1 = 0.1 °C

0158 PID COMM

VALUE 1

Data received from fieldbus for PID control (PID1 and PID2) 1 = 1

0159 PID COMM

VALUE 2

Data received from fieldbus for PID control (PID1 and PID2) 1 = 1

0160 DI 1-5 STATUS Status of digital inputs.

Example (panel):

• 10000 = DI1 is on, DI2…DI5 are off.

• 10010 = DI1 and DI4 are on, DI2, DI3 and DI5 are off.

Example (DWL2):

• 16 (decimal) = DI1 is on, DI2…DI5 are off.

• 18 (decimal) = DI1 and DI4 are on, DI2, DI3 and DI5 are

off.

0161 PULSE INPUT

FREQ

Value of frequency input in Hz

1 = 1 Hz

0162 RO STATUS

Status of relay output 1. 1 = RO is energized, 0 = RO is de-

energized.

1 = 1

0163 TO STATUS

Status of transistor output, when transistor output is used as

a digital output.

1 = 1

0164 TO

FREQUENCY

Transistor output frequency, when transistor output is used

as a frequency output.

1 = 1 Hz

0165 TIMER VALUE Timer value of timed start/stop. See parameter group

1 = 0.01 s

0166 COUNTER

VALUE

Pulse counter value of counter start/stop. See parameter

group

1 = 1

Actual signals

No.

Name/Value

Description

FbEq

Summary of Contents for ACS355 series

Page 1: ...ABB machinery drives User s manual ACS355 drives ...

Page 4: ......

Page 16: ...16 ...

Page 32: ...32 Operation principle and hardware description ...

Page 58: ...58 Electrical installation ...

Page 74: ...74 Start up control with I O and ID run ...

Page 106: ...106 Control panels ...

Page 120: ...120 Application macros ...

Page 178: ...178 Program features ...

Page 338: ...338 Fieldbus control with embedded fieldbus ...

Page 368: ...368 Fault tracing ...

Page 404: ...404 Dimension drawings ...

Page 410: ...410 Appendix Resistor braking ...

Page 434: ...434 Appendix Permanent magnet synchronous motors PMSMs ...