Actual signals and parameters 277

4012 SETPOINT

MIN

Defines the minimum value for the selected PID reference

signal source. See parameter

0.0%

-500.0…500.0% Value as a percentage.

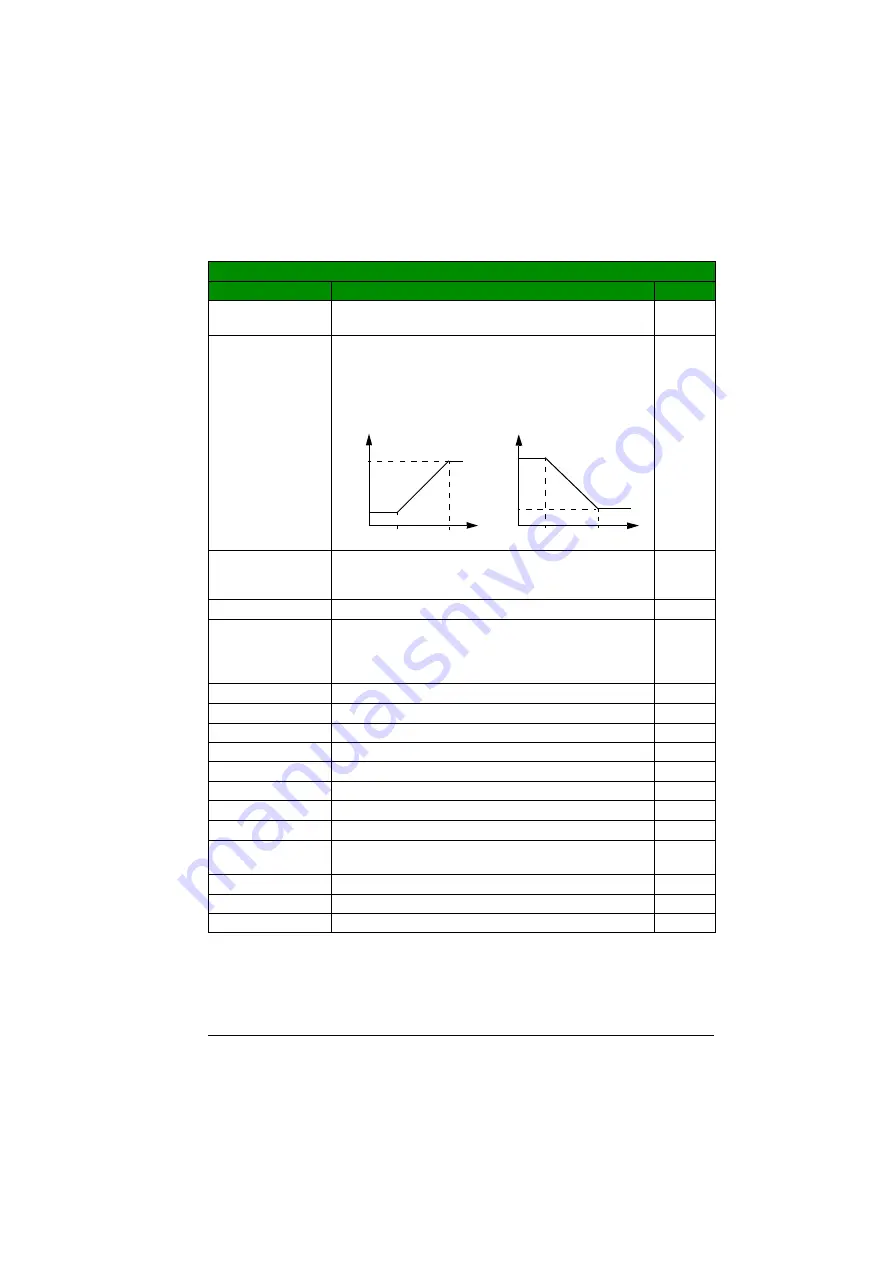

Example:

Analog input AI1 is selected as the PID reference

). The reference

minimum and maximum correspond to the

and

settings as follows:

1 = 0.1%

4013 SETPOINT

MAX

Defines the maximum value for the selected PID reference

signal source. See parameters

and

100.0%

-500.0…500.0% Value as a percentage

1 = 0.1%

4014 FBK SEL

Selects the process actual value (feedback signal) for the

process PID controller: The sources for the variables ACT1

and ACT2 are further defined by parameters

and

.

ACT1

ACT1

1

ACT1-ACT2

Subtraction of ACT1 and ACT2

2

ACT1+ACT2

Addition of ACT1 and ACT2

3

ACT1*ACT2

Multiplication of ACT1 and ACT2

4

ACT1/ACT2

Division of ACT1 and ACT2

5

MIN(ACT1,2)

Selects the smaller of ACT1 and ACT2

6

MAX(ACT1,2)

Selects the higher of ACT1 and ACT2

7

sqrt(ACT1-2)

Square root of the subtraction of ACT1 and ACT2

8

sqA1+sqA2

Addition of the square root of ACT1 and the square root of

ACT2

9

sqrt(ACT1)

Square root of ACT1

10

COMM FBK 1

Signal

value

11

COMM FBK 2

Signal

value

12

All parameters

No.

Name/Value

Description

Def/FbEq

(MAX)

(MIN)

AI1

(%)

Ref

Ref

AI1

(%)

(MIN)

(MAX)

MAX > MIN

MIN > MAX

Summary of Contents for ACS355 series

Page 1: ...ABB machinery drives User s manual ACS355 drives ...

Page 4: ......

Page 16: ...16 ...

Page 32: ...32 Operation principle and hardware description ...

Page 58: ...58 Electrical installation ...

Page 74: ...74 Start up control with I O and ID run ...

Page 106: ...106 Control panels ...

Page 120: ...120 Application macros ...

Page 178: ...178 Program features ...

Page 338: ...338 Fieldbus control with embedded fieldbus ...

Page 368: ...368 Fault tracing ...

Page 404: ...404 Dimension drawings ...

Page 410: ...410 Appendix Resistor braking ...

Page 434: ...434 Appendix Permanent magnet synchronous motors PMSMs ...