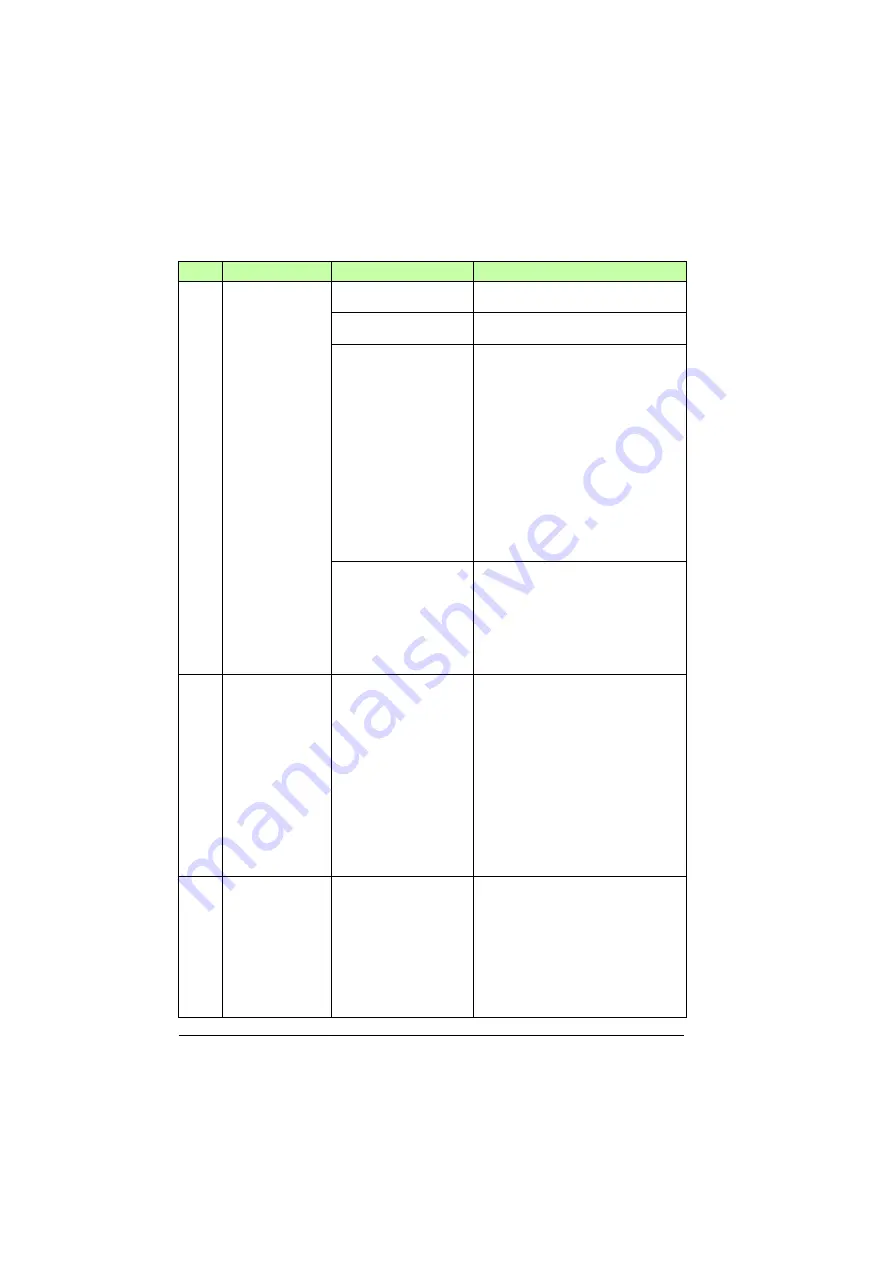

360 Fault tracing

0009

MOT OVERTEMP

(4310)

bit 8

(programmable

fault function

…

/

)

Motor temperature

estimation is too high.

Excessive load or

insufficient motor power

Check motor ratings, load and cooling.

Incorrect start-up data.

Check start-up data.

Check fault function parameters

...

Minimize IR compensation to avoid

heating (parameter

).

Check frequency of the motor (low

running frequency of motor with high

input current can cause this fault).

Let the motor cool down. The

necessary cooling time period

depends on the value of parameter

. Motor

temperature estimation is counted

down only when the drive is powered

on.

Measured motor

temperature has

exceeded the fault limit

set by parameter

.

Check value of fault limit.

Check that actual number of sensors

corresponds to value set by parameter

Let the motor cool down. Ensure

proper motor cooling: Check the

cooling fan, clean cooling surfaces,

etc.

0010

PANEL LOSS

(5300)

bit 9

(programmable

fault function

)

Control panel selected

as active control location

for drive has ceased

communicating.

Check panel connection.

Check fault function parameters.

Check parameter

.

Check control panel connector.

Refit control panel in mounting

platform.

If the drive is in external control mode

(REM) and is set to accept start/stop,

direction commands or references

through control panel:

Check group

and

settings.

0011

ID RUN FAIL

(FF84)

bit 10

Motor ID run is not

completed successfully.

Check motor connection.

Check start-up data (group

Check maximum speed (parameter

). It should be at least 80% of

motor nominal speed (parameter

).

Ensure ID run has been performed

according to instructions in section

on page

.

CODE FAULT

CAUSE

WHAT TO DO

Summary of Contents for ACS355 series

Page 1: ...ABB machinery drives User s manual ACS355 drives ...

Page 4: ......

Page 16: ...16 ...

Page 32: ...32 Operation principle and hardware description ...

Page 58: ...58 Electrical installation ...

Page 74: ...74 Start up control with I O and ID run ...

Page 106: ...106 Control panels ...

Page 120: ...120 Application macros ...

Page 178: ...178 Program features ...

Page 338: ...338 Fieldbus control with embedded fieldbus ...

Page 368: ...368 Fault tracing ...

Page 404: ...404 Dimension drawings ...

Page 410: ...410 Appendix Resistor braking ...

Page 434: ...434 Appendix Permanent magnet synchronous motors PMSMs ...