03 POWER ELECTRONICS AND CABINET FEATURES

3BHS799208 E01 REV E

ACS5000 WATER-COOLED

USER MANUAL

50/186

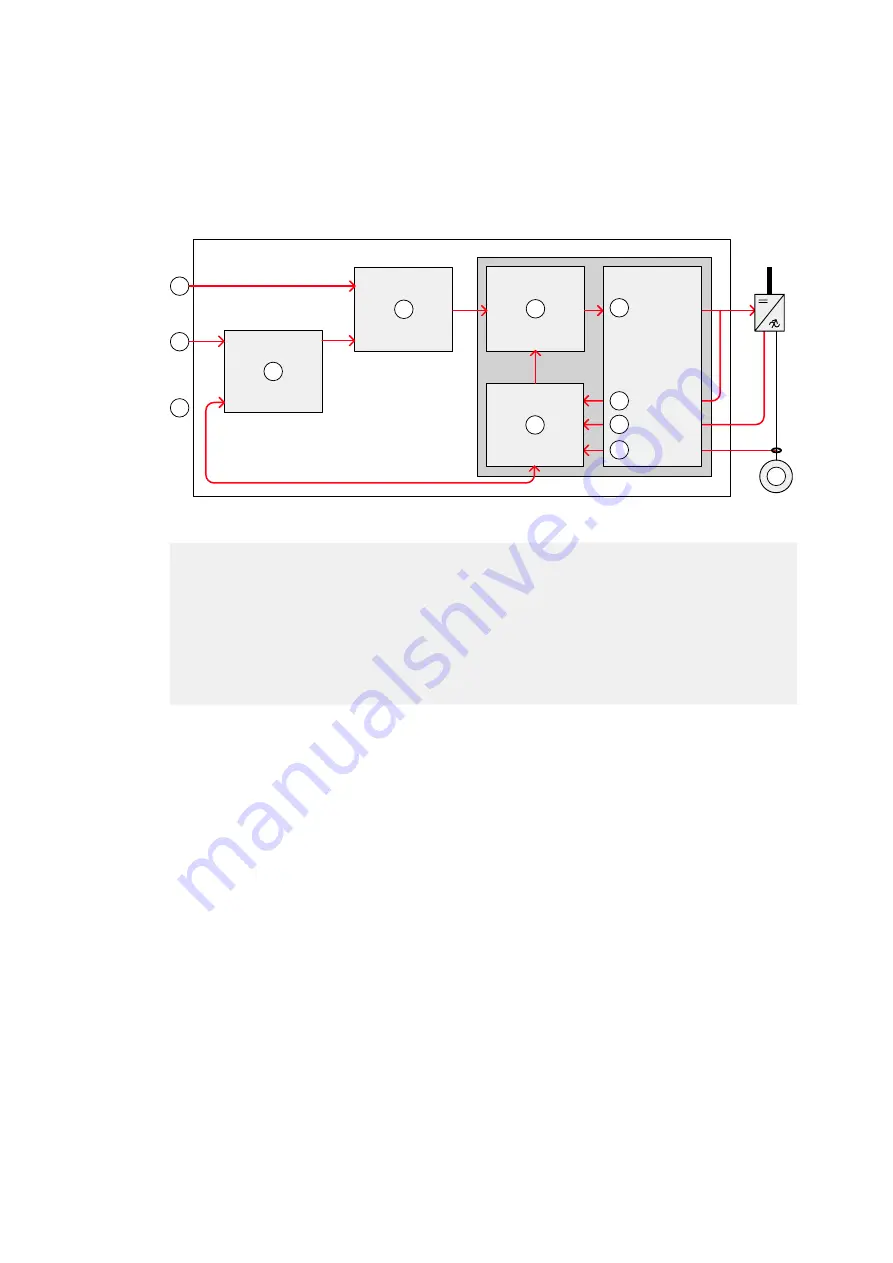

Direct torque control

The speed and torque of the motor is controlled by DTC (Direct Torque

Control). The DTC motor control platform is unique to ABB and has been

proven in all variable speed drives of the ACS product range. DTC provides

accurate speed and torque control, and high dynamic speed response.

DTC is implemented on the AMC circuit board of the INU.

Figure 3-13 DTC torque control

Switching of the semiconductors i is directly controlled in accordance

with the motor core variables flux and torque.

The measured motor currents and DC link voltages are inputs to an

adaptive motor model. The model produces exact values of torque and

flux every 25 microseconds. Motor torque and flux comparators compare

the actual values to reference values which are produced by the torque

and flux reference controllers.

Depending on the outputs from the hysteresis controllers, the switching

logic directly determines the optimum switch positions every 50 ms and

initiates switching whenever required.

Parameters

The control system is configured, customized, and tuned with a set of

application parameters. The application parameters are organized in

functional groups and have factory-set default values.

The default parameter values are adjusted during commissioning to the

specific application of the drive in order to activate the specific control,

monitoring and protection functions for the driven process, and to define

the signals and data transferred between drive and external equipment.

(1) Torque reference

(2) Speed reference

(3) Actual reference

(4) Speed controller

(5) Torque reference controller

(6) Torque-flux comparator

(7) Motor model

(8) Switching logic

(9) Switch positions

(10) Voltage

(11) Current

(12) Motor

1

2

3

4

5

6

7

8

9

10

11

12

Summary of Contents for ACS5000

Page 1: ... SYSTEM DRIVES ACS5000 water cooled User manual 5 36 MVA 6 6 9 kV ...

Page 12: ......

Page 18: ......

Page 186: ......