ACS550-02/U2 User’s Manual

77

Control panels

Output mode

In the Output mode, you can:

• monitor actual values of up to three signals in

Group 01: OPERATING DATA

• change the direction of the motor rotation

• set the speed, frequency or torque reference

• adjust the display contrast

• start, stop, change the direction and switch between local and remote control.

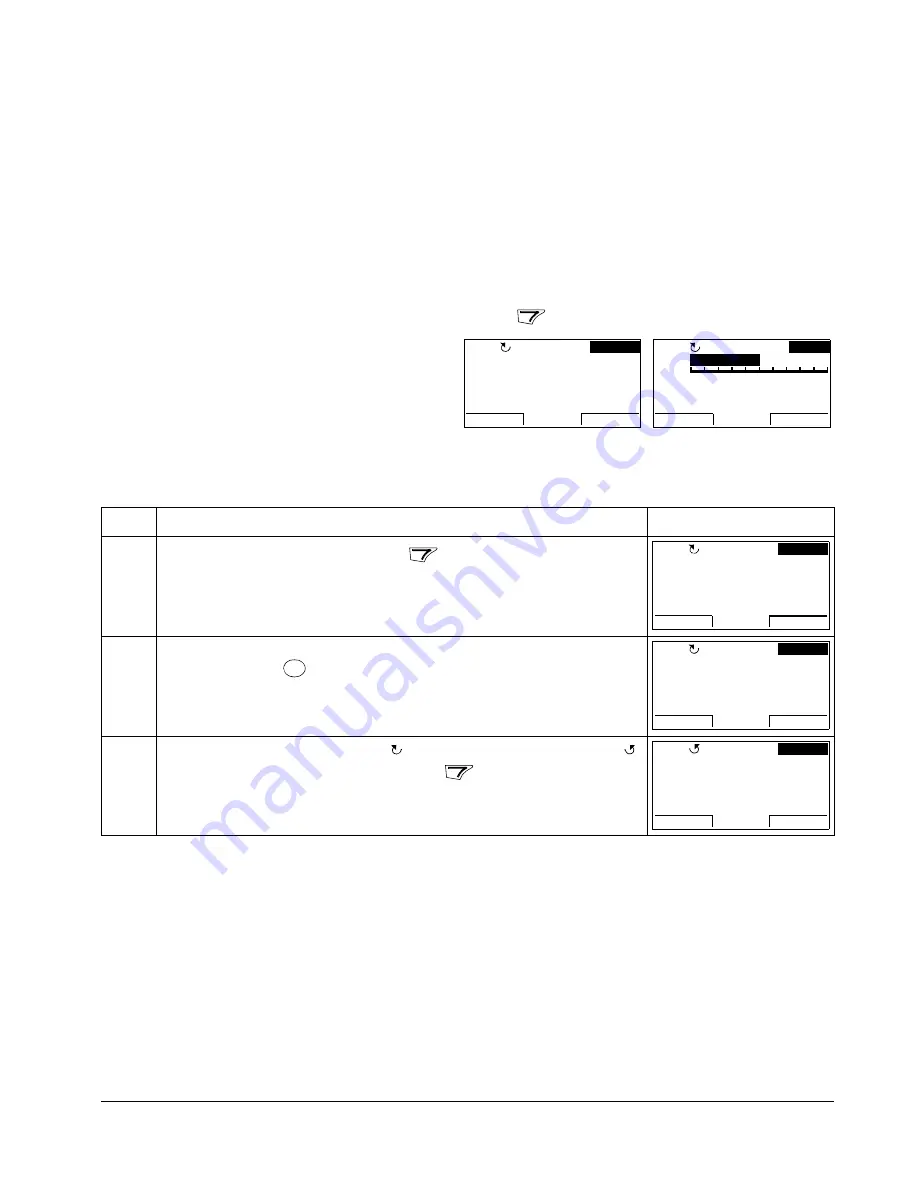

You get to the Output mode by pressing

repeatedly.

The top right corner of the

display shows the reference

value. The center can be

configured to show up to three

signal values or bar graphs; see

page

80

for instructions on

selecting and modifying the monitored signals.

How to change the direction of the motor rotation

Step

Action

Display

1.

If you are not in the Output mode, press

repeatedly until you get there.

2.

If the drive is in remote control (REM shown on the status line), switch to local

control by pressing

. The display briefly shows a message about changing

the mode and then returns to the Output mode.

3.

To change the direction from forward ( shown on the status line) to reverse (

shown on the status line), or vice versa, press

.

Note

: Parameter

1003

DIRECTION

must be set to 3 (

REQUEST

).

EXIT

5 A

1 Hz

7 %

10.

0.

49.

49.1Hz

LOC

DIR

MENU

00:00

4 A

4 %

24.

0.

5.0Hz

LOC

DIR

MENU

00:00

HZ 50%

EXIT

5 A

1 Hz

7 %

10.

0.

49.

49.1Hz

REM

DIR

MENU

00:00

LOC

REM

5 A

1 Hz

7 %

10.

0.

49.

49.1Hz

LOC

DIR

MENU

00:00

DIR

5 A

1 Hz

7 %

10.

0.

49.

49.1Hz

LOC

DIR

MENU

00:00

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com