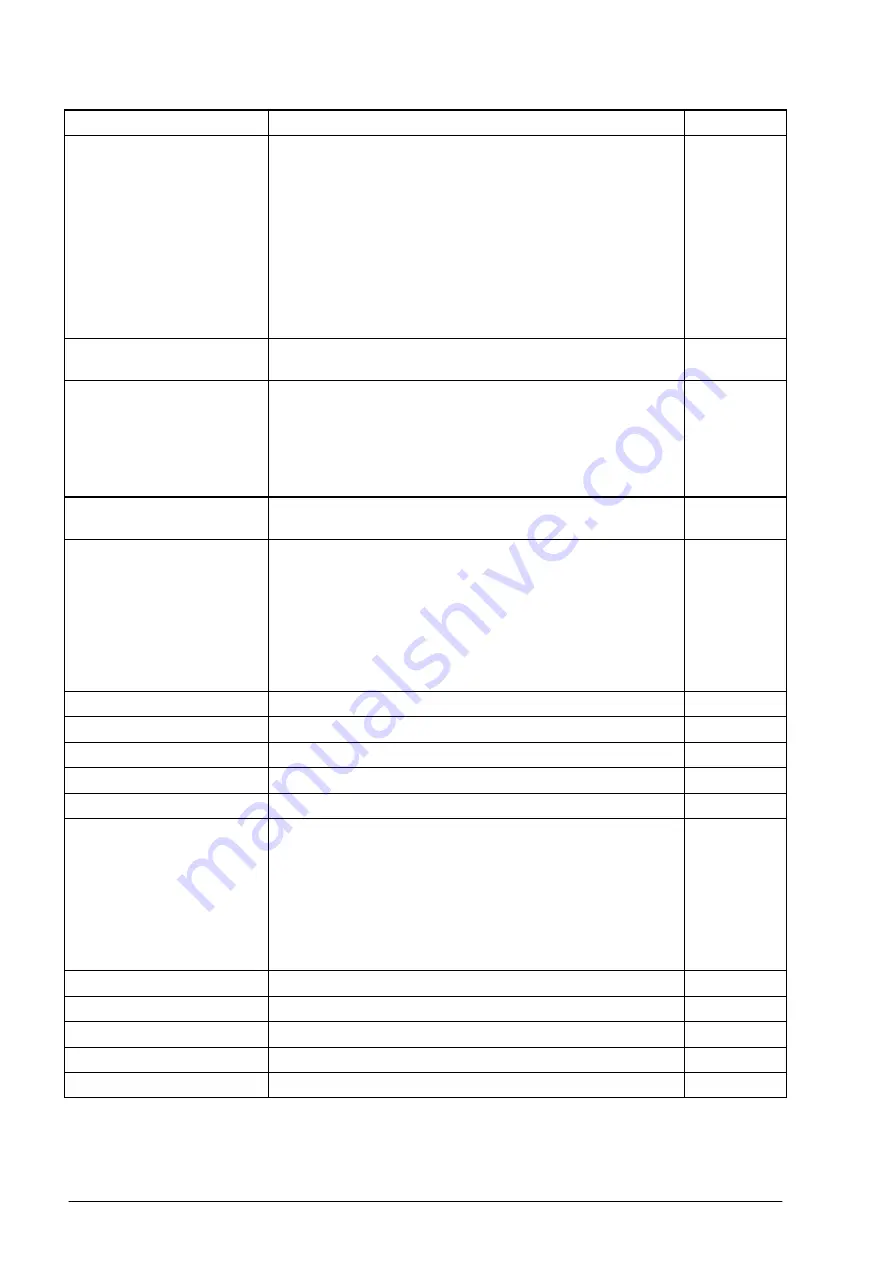

198 Parameters

Defines a minimum torque limit for the drive (in percent of

nominal motor torque). See diagram at parameter

.

The limit is effective when

• the source selected by

is 0, or

•

Note:

Do not set this parameter to 0% in an attempt to prevent

reverse rotation. In an open-loop application, that is likely to

prevent the motor from stopping altogether. To prevent

reverse rotation, use the speed/frequency limits in this

parameter group, or parameters

-300.0%

-1600.0 … 0.0%

Minimum torque limit 1.

See par.

Defines a maximum torque limit for the drive (in percent of

nominal motor torque). See diagram at parameter

.

The limit is effective when

• the source selected by

is 0, or

•

300.0%

0.0 … 1600.0%

Maximum torque 1.

See par.

Defines the source of the minimum torque limit for the drive (in

percent of nominal motor torque) when

• the source selected by parameter

is 1, or

•

.

See diagram at

Note:

Any positive values received from the selected source

are inverted.

Zero

None.

0

AI1 scaled

(see page

).

1

AI2 scaled

(see page

).

2

Minimum torque 2

6

-

Defines the source of the maximum torque limit for the drive

(in percent of nominal motor torque) when

• the source selected by parameter

is 1, or

•

.

See diagram at

Note:

Any negative values received from the selected source

are inverted.

Zero

None.

0

AI1 scaled

(see page

).

1

AI2 scaled

(see page

).

2

Maximum torque 2

6

-

No.

Name/Value

Description

Def

/

FbEq16

Summary of Contents for ACS860

Page 1: ... ABB INDUSTRIAL DRIVES ACS860 primary control program Firmware manual ...

Page 4: ......

Page 10: ...10 Table of contents ...

Page 18: ...18 Using the control panel ...

Page 24: ...24 Control locations and operating modes ...

Page 54: ...54 Program features ...

Page 78: ...78 Program features ...

Page 90: ...90 Application macros ...

Page 342: ...342 Additional parameter data ...

Page 380: ...380 Fault tracing ...

Page 381: ...Fault tracing 381 ...

Page 382: ...382 Fault tracing ...

Page 436: ...436 Control chain diagrams ...