62 Program features

DC voltage control

Overvoltage control

Overvoltage control of the intermediate DC link is typically needed when the motor is

in generating mode. The motor can generate when it decelerates or when the load

overhauls the motor shaft, causing the shaft to turn faster than the applied speed or

frequency. To prevent the DC voltage from exceeding the overvoltage control limit,

the overvoltage controller automatically decreases the generating torque when the

limit is reached. The overvoltage controller also increases any programmed

deceleration times if the limit is reached; to achieve shorter deceleration times, a

brake chopper and resistor may be required.

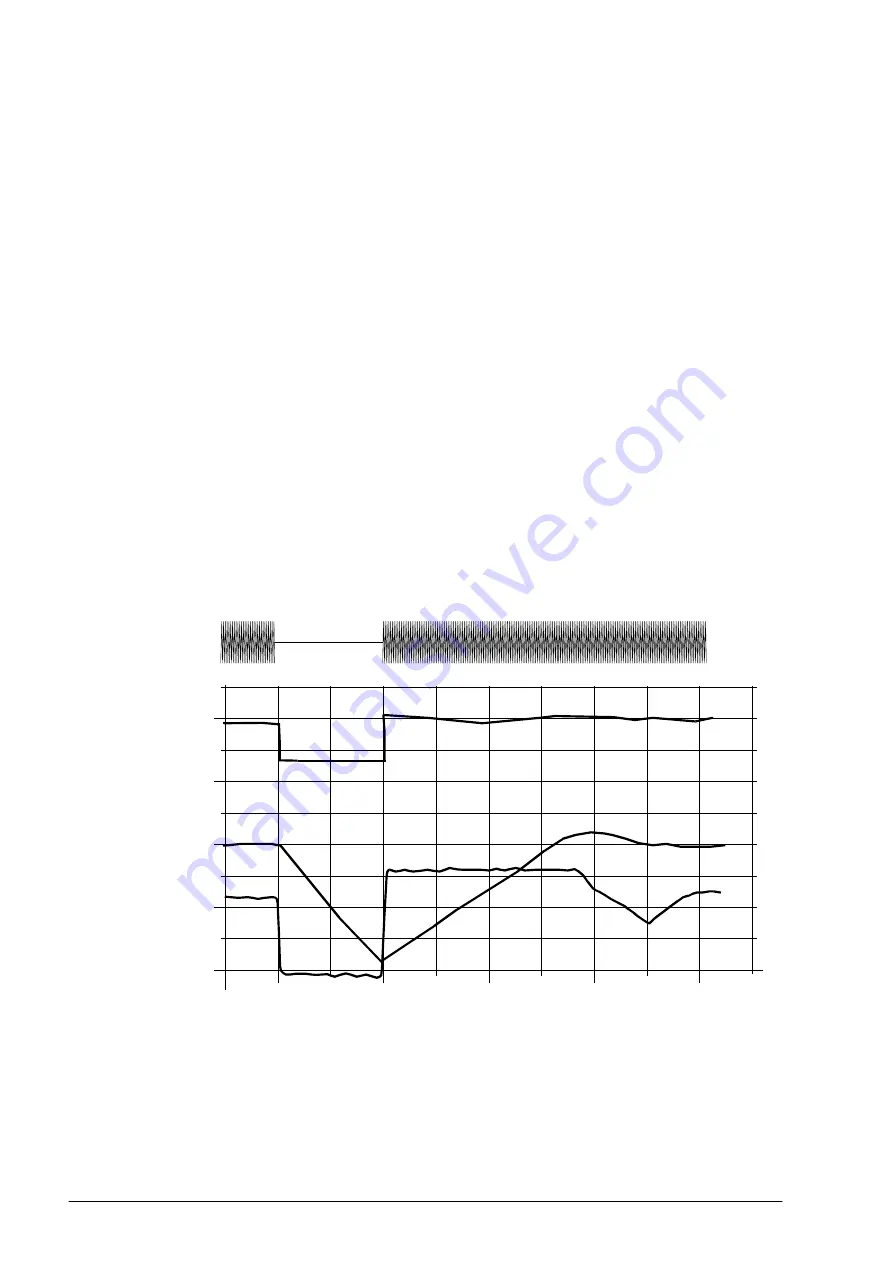

Undervoltage control (power loss ride-through)

If the incoming supply voltage is cut off, the drive will continue to operate by utilizing

the kinetic energy of the rotating motor. The drive will be fully operational as long as

the motor rotates and generates energy to the drive. The drive can continue

operation after the break if the main contactor (if present) remained closed.

Note:

Units equipped with a main contactor must be equipped with a hold circuit (e.g.

UPS) to keep the contactor control circuit closed during a short supply break.

130

260

390

520

1.6

4.8

8

11.2

14.4

t

(s)

U

DC

f

out

T

M

U

DC

= intermediate circuit voltage of the drive,

f

out

= output frequency of the drive,

T

M

= motor torque

Loss of supply voltage at nominal load (

f

out

= 40 Hz). The intermediate circuit DC voltage drops to the

minimum limit. The controller keeps the voltage steady as long as the mains is switched off. The drive runs

the motor in generator mode. The motor speed falls but the drive is operational as long as the motor has

enough kinetic energy.

U

mains

20

40

60

80

40

80

120

160

U

DC

(V DC)

f

out

(Hz)

T

M

(Nm)

Summary of Contents for ACS860

Page 1: ... ABB INDUSTRIAL DRIVES ACS860 primary control program Firmware manual ...

Page 4: ......

Page 10: ...10 Table of contents ...

Page 18: ...18 Using the control panel ...

Page 24: ...24 Control locations and operating modes ...

Page 54: ...54 Program features ...

Page 78: ...78 Program features ...

Page 90: ...90 Application macros ...

Page 342: ...342 Additional parameter data ...

Page 380: ...380 Fault tracing ...

Page 381: ...Fault tracing 381 ...

Page 382: ...382 Fault tracing ...

Page 436: ...436 Control chain diagrams ...