■

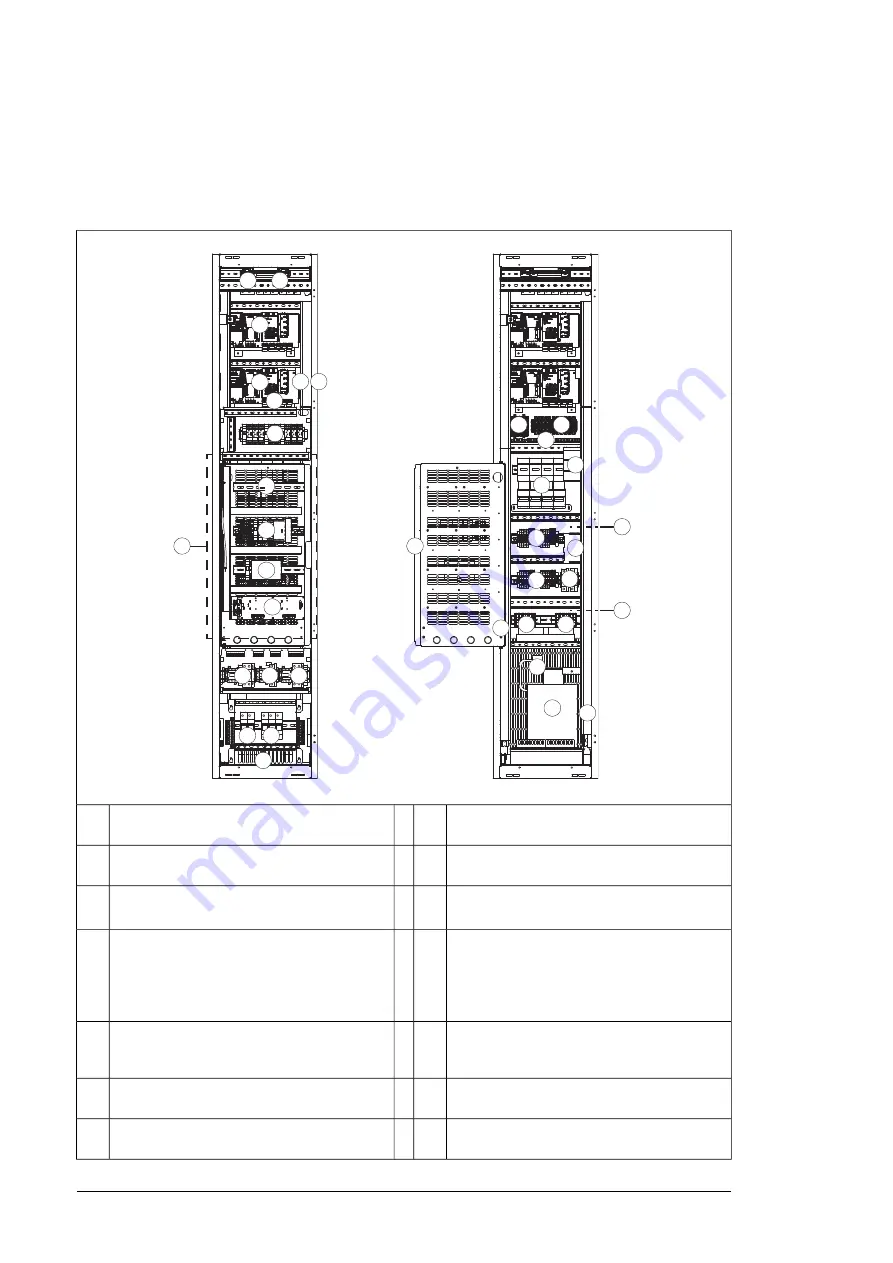

Auxiliary control cubicle (ACU) layout

A layout example of the auxiliary control cubicle (ACU) is shown below. On the left: Swing-out

frame closed, detachable mounting plates in place. On the right: Swing-out frame open,

without detachable mounting plates.

40 Operation principle and hardware description

Auxiliary control cubicle (ACU) layout

A layout example of the auxiliary control cubicle (ACU) is shown below.

1

Fuse-disconnectors F101. On the primary of

transformer T101 (item

27

).

19 Lead-through for control cables

2

Fuse-disconnectors F27 for motor cooling fan

outputs (oM602…610)

20 Terminal block X68 for FSO-xx safety functions

module (Q973)

3

Supply control unit [A51]. See chapter

Control

units of the drive

(page

123

)

21 I/O terminal block (L504). The I/O of the

inverter control unit is wired to this block.

Inverter control unit [A41]. Three optional I/O

extension, encoder interface, or fieldbus

adapter modules can be installed on the unit.

Additional modules are installed on item

13

.

See chapter

Control units of the drive

(page

123

)

22 Grounding/clamping point for control cables

Auxiliary voltage circuit breaker F112. On the

secondary of transformer T111 (item

29

).

Mounted on the right-hand inside wall.

23 24 V DC power supply and buffer module

Swing-out frame closed,

detachable mounting plates in place

Swing-out frame open,

without detachable mounting plates

3

2

4

5

1

8

9

10

11

12

13

14 15

16

17 18

19

20

21

22

23

24

25

25

26

27

28

30

31

32

33

29

34

9

6

35

7

Lead-through for control cables

19

Fuse-disconnectors F101. On the primary of

transformer T101 (item 27).

1

Terminal block (X68) for FSO-xx safety functions

module (Q973)

20

Fuse-disconnectors (F27) for motor cooling fan

outputs (oM602…610)

2

I/O terminal block (L504). The I/O of the

inverter control unit is wired to this block.

21

Supply control unit (A51). See chapter

3

Grounding/clamping point for control cables

22

Inverter control unit (A41). Three optional I/O

extension, encoder interface, or fieldbus adapter

modules can be installed on the unit. Additional

modules are installed on item 13. See chapter

Control units of the drive (page 129)

4

24 V DC power supply and buffer module

23

Auxiliary voltage circuit breaker F112. On the

secondary of transformer T111 (item 29).

Mounted on the right-hand inside wall.

5

Motor fan starters and contactors (options

+M602…610)

24

Switch (F90) for ground fault monitoring (item

12)

6

Terminal blocks (X601) for motor fan connec-

tions (oM602…610)

25

FSO-xx safety functions module (Q973

and other options requiring FSO-xx)

7

40 Operation principle and hardware description

Summary of Contents for ACS880-07

Page 1: ...ABB industrial drives Hardware manual ACS880 07 drives 560 to 2800 kW ...

Page 2: ......

Page 4: ......

Page 22: ...22 ...

Page 28: ...28 ...

Page 94: ...94 ...

Page 112: ...Electrical installation 109 5 6 4 3 112 Electrical installation ...

Page 113: ...110 Electrical installation 7 8 8 Electrical installation 113 ...

Page 114: ...Electrical installation 111 9 10 114 Electrical installation ...

Page 116: ...Electrical installation 113 4 5 3 6 7 116 Electrical installation ...

Page 118: ...2 11 b PE 10 7 5 6 8 a 360 grounding detail 118 Electrical installation ...

Page 128: ...128 ...

Page 146: ...146 ...

Page 148: ...148 ...

Page 159: ...12 Install and tighten the two M4 12 T20 screws 10 11 12 Maintenance 159 ...

Page 162: ...6 6a 6a 6b 7a 7b 7 8 8a 8b 162 Maintenance ...

Page 166: ...166 Maintenance 6 6 7 8 7 166 Maintenance ...

Page 173: ...6 Reinstall the cover removed earlier and close the cubicle door 4 4 D7T D8T Maintenance 173 ...

Page 213: ... Dimension drawing examples Frame 2 D7T 2 R8i 12 pulse A004 Dimensions 213 ...

Page 214: ...Frame 1 D8T 2 R8i IP22 214 Dimensions ...

Page 215: ...Frame 1 D8T 2 R8i IP54 B055 Dimensions 215 ...

Page 216: ...Frame 1 D8T 2 R8i with common motor terminal cubicle H359 1 2 216 Dimensions ...

Page 217: ...Frame 1 D8T 2 R8i with common motor terminal cubicle H359 2 2 Dimensions 217 ...

Page 218: ...Frame 1 D8T 2 R8i with brake choppers and resistors D150 D151 1 2 218 Dimensions ...

Page 219: ...Frame 1 D8T 2 R8i with brake choppers and resistors D150 D151 2 2 Dimensions 219 ...

Page 220: ...Frame 1 D8T 2 R8i with sine output filter E206 1 2 220 Dimensions ...

Page 221: ...Frame 1 D8T 2 R8i with sine output filter E206 2 2 Dimensions 221 ...

Page 222: ...Frame 2 D8T 2 R8i 12 pulse A004 with grounding switch F259 222 Dimensions ...

Page 223: ...Frame 2 D8T 3 R8i 1 2 Dimensions 223 ...

Page 224: ...Frame 2 D8T 3 R8i 2 2 224 Dimensions ...

Page 225: ...Frame 2 D8T 3 R8i with common motor terminal cubicle H359 1 2 Dimensions 225 ...

Page 226: ...Frame 2 D8T 3 R8i with common motor terminal cubicle H359 2 2 226 Dimensions ...

Page 227: ...Frame 2 D8T 3 R8i with top entry top exit H351 H353 1 2 Dimensions 227 ...

Page 228: ...Frame 2 D8T 3 R8i with top entry top exit 2 2 228 Dimensions ...

Page 229: ...Frame 3 D8T 4 R8i 1 2 Dimensions 229 ...

Page 230: ...Frame 3 D8T 4 R8i 2 2 230 Dimensions ...

Page 231: ...Frame 3 D8T 4 R8i with common motor terminal cubicle H359 1 2 Dimensions 231 ...

Page 232: ...Frame 3 D8T 4 R8i with common motor terminal cubicle H359 2 2 232 Dimensions ...

Page 233: ...Frame 3 D8T 4 R8i with top entry top exit H351 H353 1 2 Dimensions 233 ...

Page 234: ...Frame 3 D8T 4 R8i with top entry top exit H351 H353 2 2 234 Dimensions ...

Page 235: ...Frame 4 D8T 5 R8i 6 pulse with top entry exit UL Listed C129 1 2 Dimensions 235 ...

Page 236: ...Frame 4 D8T 5 R8i 6 pulse with top entry exit UL Listed C129 2 2 236 Dimensions ...

Page 237: ... Dimensions of empty cubicles options C199 C200 C201 IP22 IP42 Dimensions 237 ...

Page 238: ...IP54 238 Dimensions ...

Page 243: ... 1000 mm UL CSA top cable entry Dimensions 243 ...

Page 244: ... 1000 mm UL CSA bottom cable entry 244 Dimensions ...

Page 264: ...264 ...

Page 272: ... 272 ...