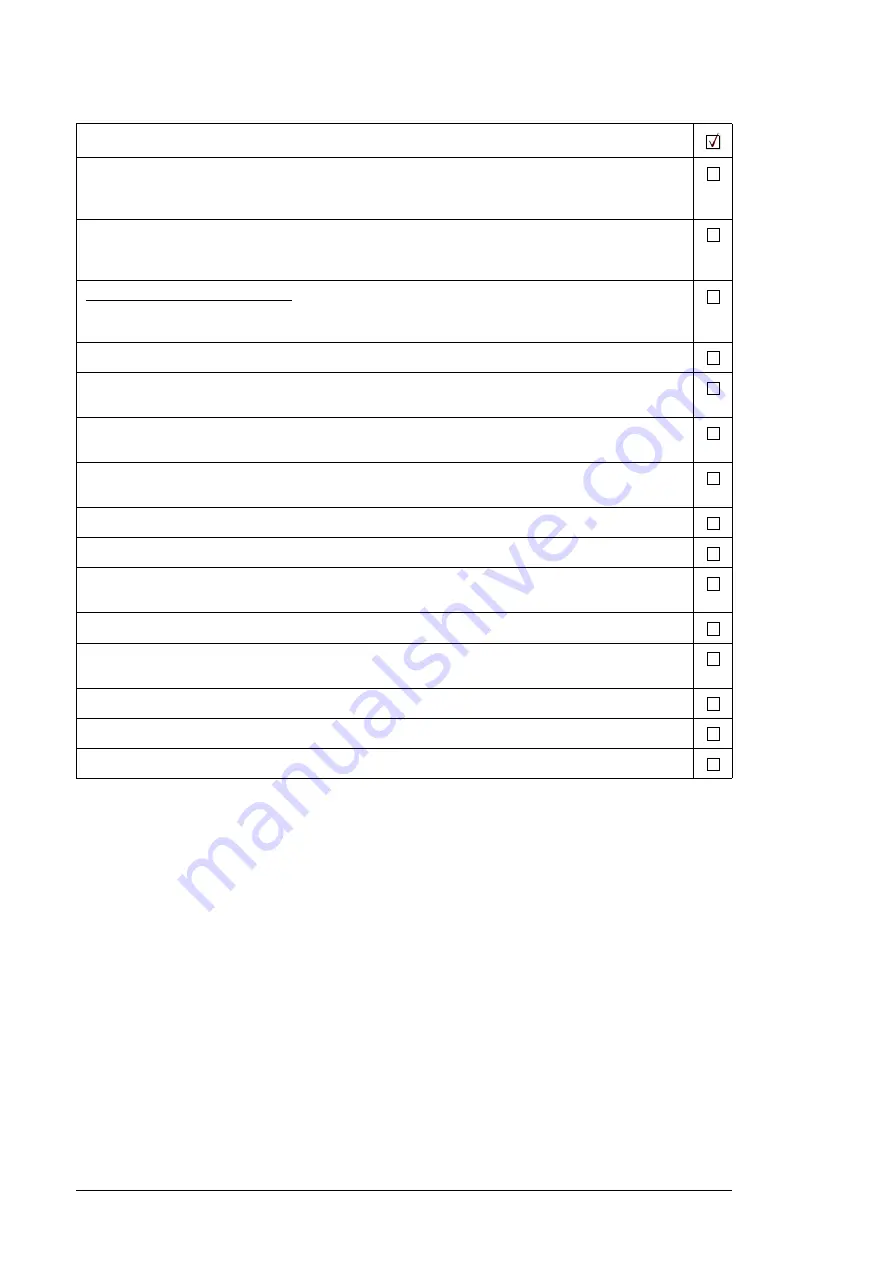

106 Installation checklist

There is an adequately sized protective earth (ground) conductor between the drive and the

switchboard, and the conductor has been connected to appropriate terminal. Proper grounding has

also been measured according to the regulations.

There is an adequately sized protective earth (ground) conductor between the motor and the drive,

and the conductor has been connected to appropriate terminal. Proper grounding has also been

measured according to the regulations.

Only for drives with D150: There is an adequately sized protective earth (ground) conductor

between the user-installed brake resistor and the drive, and the conductor has been connected to

appropriate terminal. Proper grounding has also been measured according to the regulations.

The supply voltage matches the nominal input voltage of the drive. Check the type designation label.

The voltage setting of the auxiliary voltage transformers T21 (standard), T101 (option-specific) and

T111 (option-specific) is correct.

The input power cable has been connected to the appropriate terminals, the phase order is right, and

the terminals have been tightened. (Pull the conductors to check.)

The motor cable has been connected to the appropriate terminals, the phase order is right, and the

terminals have been tightened. (Pull the conductors to check.)

The motor cable (and brake resistor cable, if present) has been routed away from other cables.

No power factor compensation capacitors have been connected to the motor cable.

The external brake resistor (if present) has been connected to the appropriate terminals, and the

terminals have been tightened. (Pull the conductors to check.)

The brake resistor cable has been routed away from other cables.

The control cables have been connected to the appropriate terminals, and the terminals have been

tightened. (Pull the conductors to check.)

There are no tools, foreign objects or dust from drilling inside the drive.

All shrouds and cover of the motor connection box are in place. Cabinet doors have been closed.

The motor and the driven equipment are ready for start.

Check that …

Summary of Contents for ACS880-07XT Series

Page 1: ...ABB industrial drives Hardware manual ACS880 07XT drives 400 to 1200 kW ...

Page 4: ......

Page 12: ...12 ...

Page 20: ...20 Safety instructions ...

Page 26: ...26 Introduction to the manual ...

Page 54: ...54 Mechanical installation ...

Page 89: ...Electrical installation 89 PE 11 8 4 9 11 ...

Page 94: ...94 Electrical installation ...

Page 112: ...112 Fault tracing ...

Page 123: ...Maintenance 123 5 6 7 ...

Page 124: ...124 Maintenance 8 10 9 ...

Page 126: ...126 Maintenance 6 5 4 ...

Page 127: ...Maintenance 127 9 8 7 ...

Page 128: ...128 Maintenance 12 11 10 ...

Page 149: ...Dimensions 149 Dimension drawing examples Frame 2 R11 R10 with brake chopper ...

Page 150: ...150 Dimensions Frame 2 R11 R10 without brake chopper ...

Page 153: ...Dimensions 153 Location of input terminals ACS880 07XT 12 pulse ...

Page 154: ...154 Dimensions Location of output terminals ACS880 07XT R10 with du dt ...

Page 155: ...Dimensions 155 Location of output terminals ACS880 07XT R10 without du dt ...

Page 156: ...156 Dimensions Location of output terminals ACS880 07XT R11 with du dt ...

Page 157: ...Dimensions 157 Location of output terminals ACS880 07XT R11 without du dt ...

Page 158: ...158 Dimensions Location of PE terminals ACS880 07XT ...

Page 159: ...Dimensions 159 Location of resistor terminals ACS880 07XT R10 ...

Page 160: ...160 Dimensions Location of resistor terminals ACS880 07XT R11 ...

Page 168: ...www abb com drives www abb com drivespartners 3ABD00043579 Rev C EN 2018 01 01 Contact us ...