Electrical installation 45

4. Tighten the two tightening screws so that the EMI conductive cushions press tightly

round the bare shield.

5. Secure the cables mechanically at the lead-through strain relief.

6. Keep the shields continuous as close to the connection terminals as possible.

Note:

If the outer surface of the shield is non-conductive:

•

Cut the shield at the midpoint of the bare part. Be careful not to cut the conductors or

the grounding wire (if present).

•

Turn the shield inside out to expose its conductive surface.

•

Cover the turned shield and the stripped cable with copper foil to keep the shielding

continuous.

Note for top entry of cables:

When each cable has its own rubber grommet, sufficient IP

and EMC protection can be achieved. However, if very many control cables come to one

cabinet, plan the installation beforehand as follows:

1. Make a list of the cables coming to the cabinet.

2. Sort the cables going to the left into one group and the cables going to the right into

another group to avoid unnecessary crossing of cables inside the cabinet.

3. Sort the cables in each group according to size.

4. Group the cables for each grommet as follows ensuring that each cable has a proper

contact to the cushions on both sides.

Cable diameter in mm

Max. number of cables per grommet

< 13

4

< 17

3

< 25

2

> 25

1

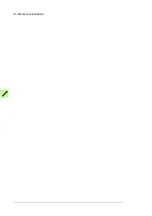

a

EMI conductive cushion

b

Strain relief

c

Grommet

d

Lead-through plate

a

b

c

d

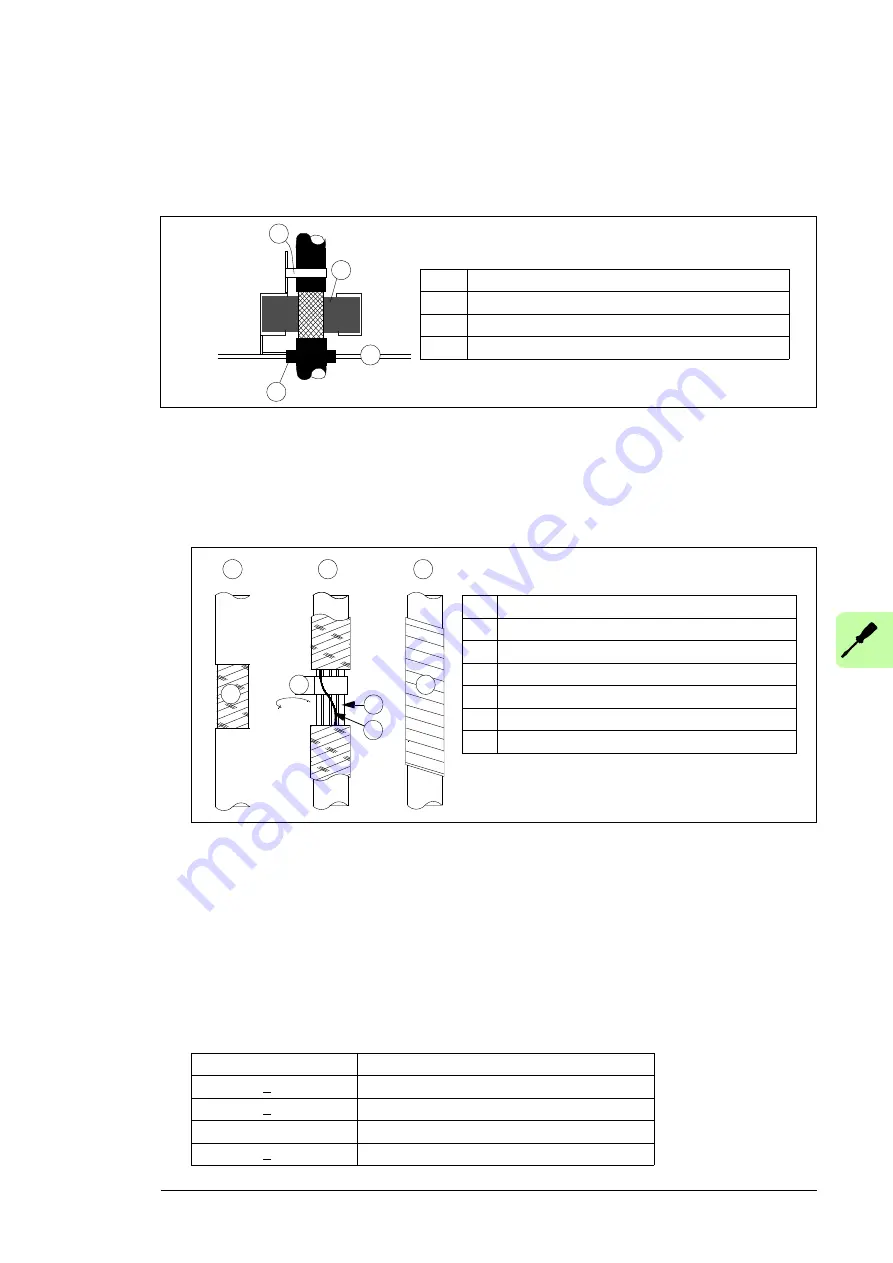

A

Stripped cable

B

Conductive surface of the shield exposed

C

Stripped part covered with copper foil

1

Cable shield

2

Copper foil

3

Shielded twisted pair

4

Grounding wire

1

A

B

C

2

2

3

4

Summary of Contents for ACS880-1607

Page 1: ...ABB industrial drives Hardware manual ACS880 1607 DC DC converter units ...

Page 4: ......

Page 12: ...12 Introduction to the manual ...

Page 34: ...34 Mechanical installation ...

Page 40: ...40 Guidelines for planning electrical installation ...

Page 52: ...52 Electrical installation ...

Page 68: ...68 Start up ...

Page 80: ...80 Maintenance 7 3 4 5 6 ...

Page 82: ...82 Maintenance 3 4 5 6 7 8 9 9 ...

Page 85: ...Maintenance 85 12 Install and tighten the two screws 10 11 12 ...

Page 92: ...92 Maintenance 3 6 4 5 4 7a 7b 7b ...

Page 93: ...Maintenance 93 9 8 8 10 11 ...

Page 96: ...96 Maintenance 4 8 6 7 5 3 ...

Page 97: ...Maintenance 97 9 ...

Page 118: ...118 Dimensions Dimension drawings Frame 1 R8i bottom cable entry ...

Page 119: ...Dimensions 119 Frame 1 R8i top cable entry ...

Page 122: ...www abb com drives www abb com drivespartners 3AXD50000023644 Rev B EN 2017 01 30 Contact us ...