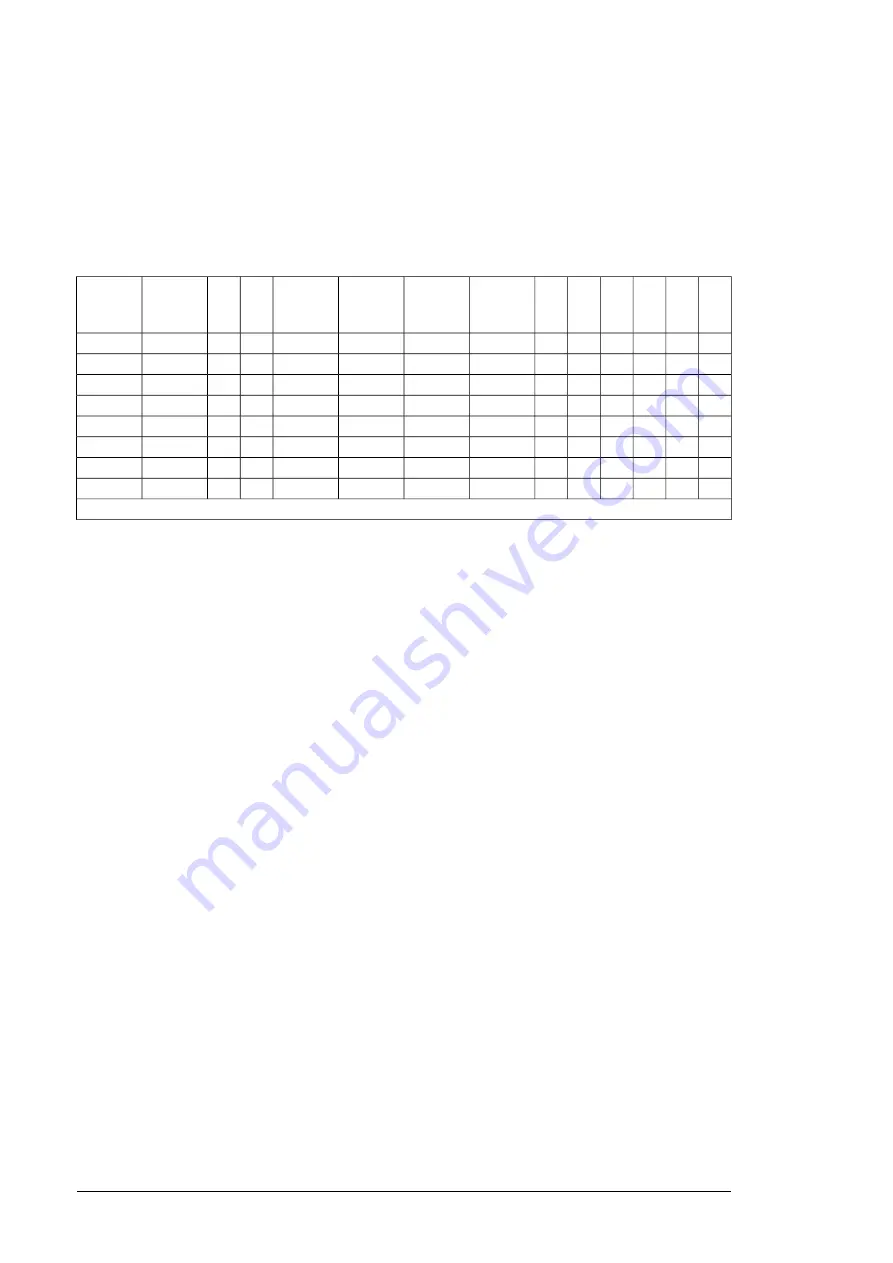

Safety data

The safety data for the Safe torque off function is given below.

Note:

The safety data is calculated for redundant use, and does not apply if both STO channels

are not used.

T

M

(a)

CCF

HFT

SC

Cat.

DC

(%)

MTTF

D

(a)

PFD

avg

(T

1

= 5 a)

PFD

avg

(T

1

= 2 a)

PFH

(T

1

= 20 a)

(1/h)

SFF

(%)

PL

SIL/

SILCL

Frame size

20

80

1

3

3

≥90

23970

1.1E-06

4.5E-07

5.0E-11

>99

e

3

R8i

20

80

1

3

3

≥90

16330

1.3E-06

5.5E-07

6.2E-11

>99

e

3

2×R8i

20

80

1

3

3

≥90

12390

1.6E-06

6.5E-07

7.3E-11

>99

e

3

3×R8i

20

80

1

3

3

≥90

9980

1.9E-06

7.6E-07

8.4E-11

>99

e

3

4×R8i

20

80

1

3

3

≥90

8360

2.1E-06

8.6E-07

9.5E-11

>99

e

3

5×R8i

20

80

1

3

3

≥90

7190

2.4E-06

9.6E-07

1.1E-10

>99

e

3

6×R8i

20

80

1

3

3

≥90

6310

2.6E-06

1.1E-06

1.2E-10

>99

e

3

7×R8i

20

80

1

3

3

≥90

5620

2.8E-06

1.2E-06

1.3E-10

>99

e

3

8×R8i

3AXD10000078136 F

•

The following temperature profile is used in safety value calculations:

•

670 on/off cycles per year with Δ

T

= 71.66 °C

•

1340 on/off cycles per year with Δ

T

= 61.66 °C

•

30 on/off cycles per year with Δ

T

= 10.0 °C

•

32 °C board temperature at 2.0% of time

•

60 °C board temperature at 1.5% of time

•

85 °C board temperature at 2.3% of time.

•

The STO is a type B safety component as defined in IEC 61508-2.

•

Relevant failure modes:

•

The STO trips spuriously (safe failure)

•

The STO does not activate when requested

•

A fault exclusion on the failure mode “short circuit on printed circuit board” has been

made (EN 13849-2, table D.5). The analysis is based on an assumption that one

failure occurs at one time. No accumulated failures have been analyzed.

•

STO response times:

•

STO reaction time (shortest detectable break): 1 ms

•

STO response time: 2 ms (typical), 25 ms (maximum)

•

Fault detection time: Channels in different states for longer than 200 ms

•

Fault reaction time: Fault detection time + 10 ms

•

Indication delays:

•

STO fault indication (parameter

31.22

) delay: < 500 ms

•

STO warning indication (parameter

31.22

) delay: < 1000 ms

196 The Safe torque off function

Summary of Contents for ACS880-37LC

Page 1: ... ABB INDUSTRIAL DRIVES ACS880 37LC drives Hardware manual ...

Page 2: ......

Page 4: ......

Page 78: ...78 ...

Page 116: ...116 ...

Page 134: ...5 Set the real time clock 134 Maintenance ...

Page 144: ...144 ...

Page 167: ... Dimension drawing examples ACS880 37LC 0390A 7 with main contactor Dimensions 167 ...

Page 169: ...ACS880 37LC 1270A 7 with common motor terminal cubicle Dimensions 169 ...

Page 170: ...ACS880 37LC 1940A 7 with common motor terminal cubicle 170 Dimensions ...

Page 172: ...Location and size of input terminals Contact ABB for details 172 Dimensions ...

Page 174: ...Inverter module cubicle with two R8i modules bottom cable exit 174 Dimensions ...

Page 175: ...Inverter module cubicle with three R8i modules bottom cable exit Dimensions 175 ...

Page 176: ...Brake chopper cubicle D150 176 Dimensions ...

Page 178: ...Cubicle width 300 mm top cable exit 178 Dimensions ...

Page 179: ...Cubicle width 400 mm bottom cable exit Dimensions 179 ...

Page 180: ...Cubicle width 400 mm top cable exit 180 Dimensions ...

Page 181: ...Cubicle width 600 mm bottom cable exit Dimensions 181 ...

Page 182: ...Cubicle width 600 mm top cable exit 182 Dimensions ...

Page 198: ...198 ...

Page 200: ...200 ...