value (based on a motor thermal model) or an actual temperature indication given by motor

temperature sensors.

The motor thermal protection model supports thermal memory retention and speed sensitivity.

The user can tune the thermal model further by feeding in additional motor and load data.

The most common temperature sensors are:

•

motor sizes IEC180…225: thermal switch, for example Klixon

•

motor sizes IEC200…250 and larger: PTC or Pt100.

See the firmware manual for more information on the motor thermal protection.

■

Protecting the drive against ground faults

The drive is equipped with an internal ground fault protective function to protect the unit

against ground faults in the motor and motor cable. This function is not a personnel safety

or a fire protection feature. See the firmware manual for more information.

Residual current device compatibility

The drive is suitable to be used with residual current devices of Type B.

Note:

As standard, the drive contains capacitors connected between the main circuit and the

frame. These capacitors and long motor cables increase the ground leakage current and

may cause nuisance faults in circuit breakers.

■

Implementing the emergency stop function

You can order the drive with an emergency stop function.

See the appropriate manual for more information.

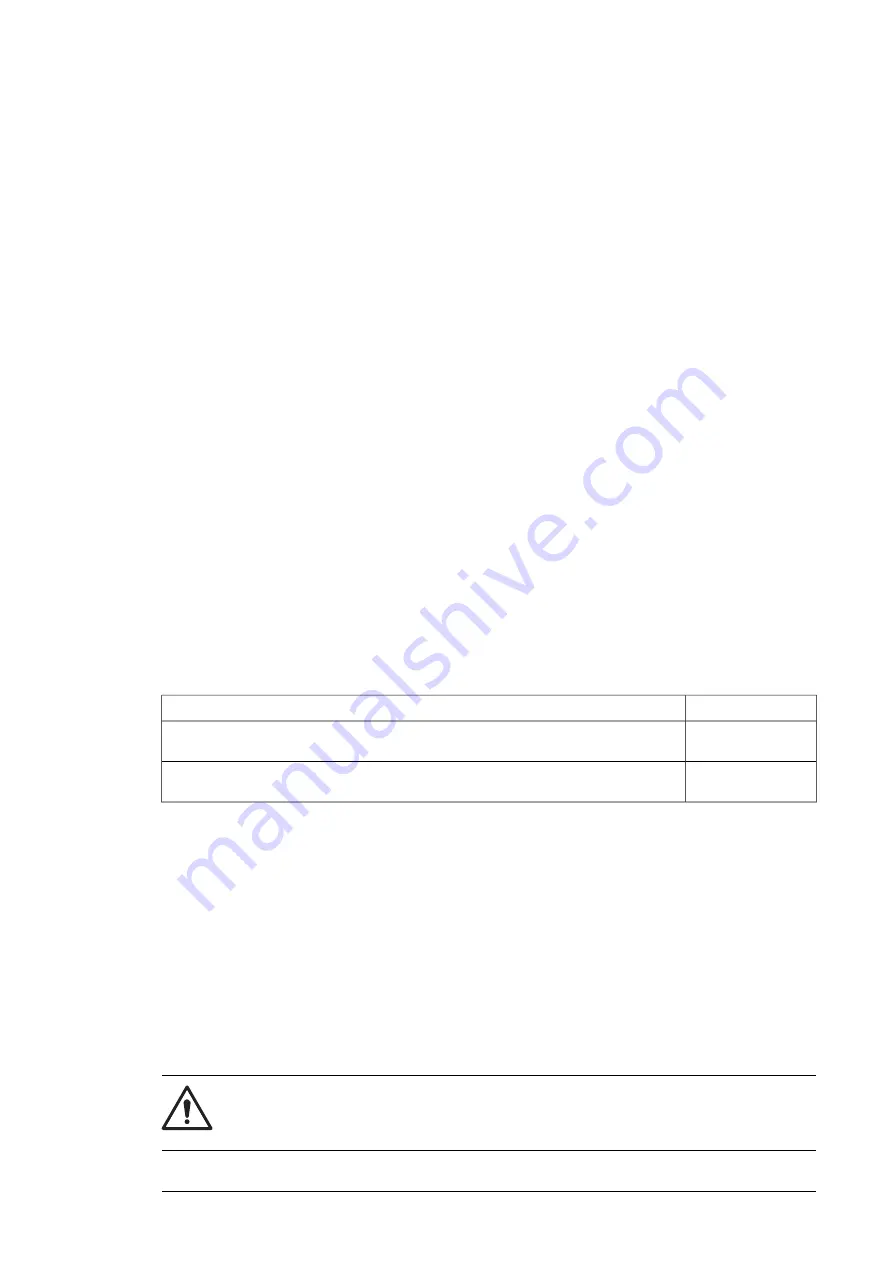

Code

Name

3AUA0000119895

Emergency stop, stop category 0 (Q951) for ACS880-07/17/17LC/37/37LC drives

user's manual

3AUA0000119896

Emergency stop, stop category 1 (Q952) for ACS880-07/17/17LC/37/37LC drives

user's manual

■

Implementing the Safe Torque Off function

See chapter

on page

■

Implementing the Power loss ride-through function

Implement the power-loss ride-through function as follows:

•

Check that the power-loss ride-through function of the drive is enabled with parameter

30.31

.

•

Set parameter

21.01

(in vector mode) or parameter

21.19

(in scalar mode) to make

flying start (starting into a rotating motor) possible. If the installation is equipped with a

main contactor, prevent its tripping at the input power break. For example, use a time

delay relay (hold) in the contactor control circuit.

WARNING!

Make sure that the flying restart of the motor will not cause any danger. If you are

in doubt, do not implement the Power-loss ride-through function.

Guidelines for planning the electrical installation 69

Summary of Contents for ACS880-37LC

Page 1: ... ABB INDUSTRIAL DRIVES ACS880 37LC drives Hardware manual ...

Page 2: ......

Page 4: ......

Page 78: ...78 ...

Page 116: ...116 ...

Page 134: ...5 Set the real time clock 134 Maintenance ...

Page 144: ...144 ...

Page 167: ... Dimension drawing examples ACS880 37LC 0390A 7 with main contactor Dimensions 167 ...

Page 169: ...ACS880 37LC 1270A 7 with common motor terminal cubicle Dimensions 169 ...

Page 170: ...ACS880 37LC 1940A 7 with common motor terminal cubicle 170 Dimensions ...

Page 172: ...Location and size of input terminals Contact ABB for details 172 Dimensions ...

Page 174: ...Inverter module cubicle with two R8i modules bottom cable exit 174 Dimensions ...

Page 175: ...Inverter module cubicle with three R8i modules bottom cable exit Dimensions 175 ...

Page 176: ...Brake chopper cubicle D150 176 Dimensions ...

Page 178: ...Cubicle width 300 mm top cable exit 178 Dimensions ...

Page 179: ...Cubicle width 400 mm bottom cable exit Dimensions 179 ...

Page 180: ...Cubicle width 400 mm top cable exit 180 Dimensions ...

Page 181: ...Cubicle width 600 mm bottom cable exit Dimensions 181 ...

Page 182: ...Cubicle width 600 mm top cable exit 182 Dimensions ...

Page 198: ...198 ...

Page 200: ...200 ...