•

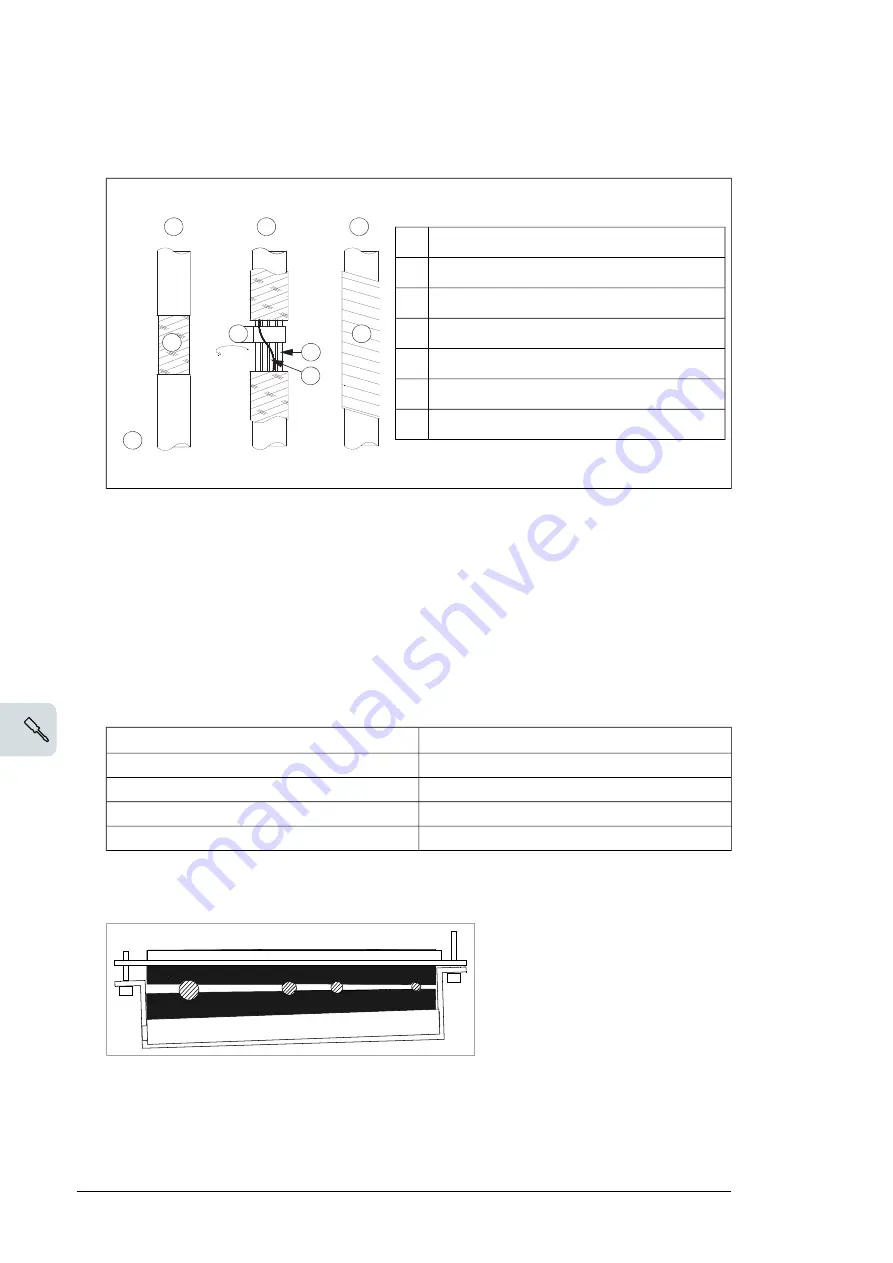

Cover the turned shield and the stripped cable with copper foil to keep the shielding

continuous.

1

A

B

C

2

2

3

4

5

Stripped cable

A

Conductive surface of the shield exposed

B

Stripped part covered with copper foil

C

Cable shield

1

Copper foil

2

Shielded twisted pair

3

Grounding wire

4

Note for top entry of cables:

When each cable has its own rubber grommet, sufficient IP

and EMC protection can be achieved. However, if very many control cables come to one

cabinet, plan the installation beforehand as follows:

1.

Make a list of the cables coming to the cabinet.

2.

Sort the cables going to the left into one group and the cables going to the right into

another group to avoid unnecessary crossing of cables inside the cabinet.

3.

Sort the cables in each group according to size.

4.

Group the cables for each grommet as follows ensuring that each cable has a proper

contact to the cushions on both sides.

Max. number of cables per grommet

Cable diameter in mm

4

≤ 13

3

≤ 17

2

< 25

1

≥ 25

5.

Arrange the bunches according to size from thickest to the thinnest between the EMI

conductive cushions.

Electrical installation 99

5.

Arrange the bunches according to size from thickest to the thinnest between the EMI

conductive cushions.

6.

If more than one cable go through a grommet, seal the grommet by applying Loctite

5221 (catalogue number 25551) inside the grommet.

Routing the control cables inside the cabinet

Use the existing trunking in the cabinet wherever possible. Use sleeving if cables are laid

against sharp edges. When running cables to or from the swing-out frame, leave enough

slack at the hinge to allow the frame to open fully.

Connecting to the inverter control unit (A41)

Connect the conductors to the appropriate terminals (see page

127

) of the control unit or

terminal block X504 (L504).

Connect the inner twisted pair shields and all separate grounding wires to the grounding

clamps below the control unit.

The drawing below represents a drive with additional I/O terminal block (L504).

Without the block, the grounding is made the same way.

Notes:

•

Do not ground the outer shield of the cable here since it is grounded at the lead-

through.

•

Keep any signal wire pairs twisted as close to the terminals as possible. Twisting the

wire with its return wire reduces disturbances caused by inductive coupling.

6.

If more than one cable go through a grommet, seal the grommet by applying Loctite

5221 (catalogue number 25551) inside the grommet.

82 Electrical installation

Summary of Contents for ACS880-37LC

Page 1: ... ABB INDUSTRIAL DRIVES ACS880 37LC drives Hardware manual ...

Page 2: ......

Page 4: ......

Page 78: ...78 ...

Page 116: ...116 ...

Page 134: ...5 Set the real time clock 134 Maintenance ...

Page 144: ...144 ...

Page 167: ... Dimension drawing examples ACS880 37LC 0390A 7 with main contactor Dimensions 167 ...

Page 169: ...ACS880 37LC 1270A 7 with common motor terminal cubicle Dimensions 169 ...

Page 170: ...ACS880 37LC 1940A 7 with common motor terminal cubicle 170 Dimensions ...

Page 172: ...Location and size of input terminals Contact ABB for details 172 Dimensions ...

Page 174: ...Inverter module cubicle with two R8i modules bottom cable exit 174 Dimensions ...

Page 175: ...Inverter module cubicle with three R8i modules bottom cable exit Dimensions 175 ...

Page 176: ...Brake chopper cubicle D150 176 Dimensions ...

Page 178: ...Cubicle width 300 mm top cable exit 178 Dimensions ...

Page 179: ...Cubicle width 400 mm bottom cable exit Dimensions 179 ...

Page 180: ...Cubicle width 400 mm top cable exit 180 Dimensions ...

Page 181: ...Cubicle width 600 mm bottom cable exit Dimensions 181 ...

Page 182: ...Cubicle width 600 mm top cable exit 182 Dimensions ...

Page 198: ...198 ...

Page 200: ...200 ...