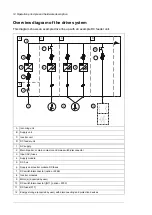

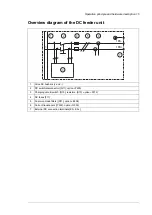

Overview diagram of the DC feeder unit

-

+

1ES-

1ES+

1

2

3

4

5

6

7

Drive DC busbars (+ and -)

1

DC switch/disconnector ([Q11], F290)

2

Charging circuit (switch: [Q10], resistors: [R10], F272)

3

DC fuses [F11]

4

Common mode filters ([R11], E208)

5

Current transducers ([T353], G353)

6

External DC connection terminals [ES-, ES+]

7

Operation principle and hardware description 15

Summary of Contents for ACS880-7107LC DC

Page 1: ... ABB INDUSTRIAL DRIVES ACS880 7107LC DC feeder unit Hardware manual ...

Page 2: ......

Page 4: ......

Page 8: ...8 ...

Page 12: ...12 ...

Page 22: ...22 ...

Page 36: ...36 ...

Page 40: ...40 ...

Page 44: ...44 ...

Page 50: ...50 ...

Page 52: ...52 ...

Page 55: ...Terminal and cable entry data for the power cables Technical data 55 ...