12

1

2

3

4

5

6

7

8

9

10 11

12 13

14 15 16 17 18

19 20 21 22 23 24

1

2

3

4

5

6

7

8

9

10 11 12 13

L

N

E

L

N

E

14 15 16 17 18 19

20 21 22 23 24 25 26

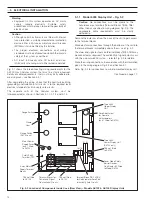

Note

. The number of terminals, cable glands, low-flow alarms, PSU's and zener barriers

(flow alarms) vary according to ordering information details specified.

Relay No. 2

Relay No. 1

POWER

SUPPLY

UNIT No 1

POWER

SUPPLY

UNIT No 2

No. 1 No. 2

BARRIER FLOW

ALARM

E SCR S1 S2 0V 0V -12V+12V

CH 1

I N COM NC NO

E SCR S1 S2 0V 0V -12V+12V

CH 1

I N COM NC NO

1 2

1 2

3 4

3 4

Barriers

Low Flow Alarm

Relay 2 (if fitted)

Mains Power

Cable Glands

Earth Point (Ground)

Low Flow Alarm

Relay 1 (if fitted)

Cable Glands for Cable

Terminations in

Hazardous Areas

Cable Glands for

Cable Terminations

in Safe Areas

To Cubicle Earth

Power Supply

Unit 2 (if fitted)

Power Supply

Unit 1

Terminal Block

MAINS

TERMINAL

BLOCK

KATHAROMETER

TERMINAL BLOCK

LOW FLOW

ALARMS

ALARMS AND

RETRANS

4.2

Sample Gas Interconnections

Note

. A hazardous mixture of hydrogen in air could develop in the event of leakage from the sample gas system. Mount

katharometer analyzer panels in a ventilated area.

The sample pressure must not exceed 0.35 bar (Gauge) for Model 6540 203 or 10 bar (Gauge) for Model 6548 000.

The incoming sample gas temperature must not exceed 55°C (131°F). Ideally the sample gas temperature should be allowed to reach

ambient temperature before entry to the Katharometer unit.

If there is a risk of significant particle contamination incorporate a suitable 1µm filter unit in the system before the sample gas enters

the analyzer system.

Compression couplings are supplied at the sample inlet and outlet to the katharometer panel. These couplings are suitable for

connecting 8mm (0.31 in.) (Model 006540 203) or 6mm (0.24 in.) (Model 006548 000) outside diameter metal tube. It is

recommended that stainless steel tube is used.

The complete tubing system should be tested for leaks in accordance with the requirements of the responsible authority.

Fig. 4.5 Location of Main Components on Cubicle Backplate

…4

MECHANICAL INSTALLATION