B2342

Emax VF

22/66

Doc. no.

Model

Apparatus

Scale

Page No

1SDH000909R0001

8.3.9. Maintenance operations; final checks

- Refit all parts and always reconnect the auxiliary supply.

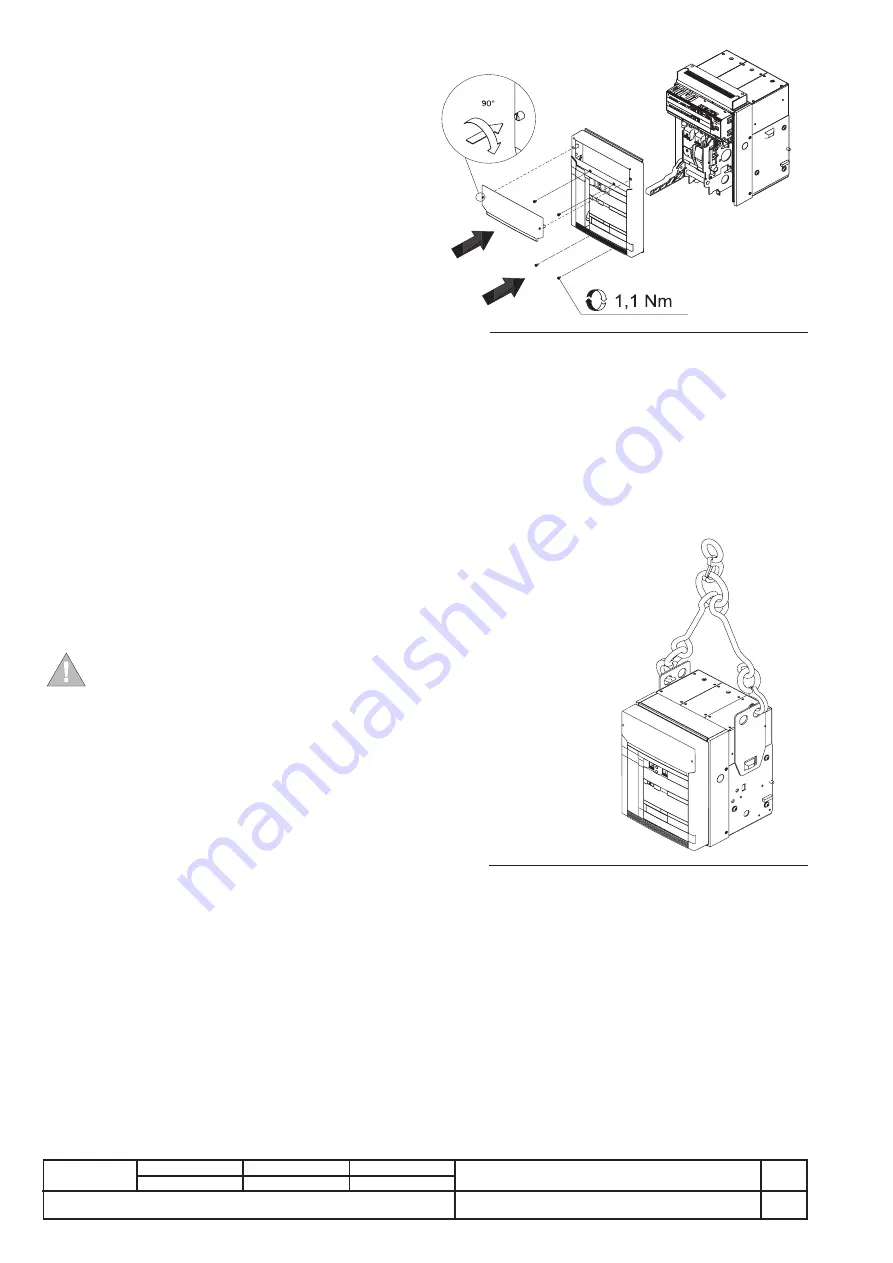

- Refit the cap as indicated in figure 37.

- Return the movable part to the TEST-ISOLATED position.

- Use the different auxiliaries in turn to run the following 10 op-

erations:

- Opening (both local and remote as applicable)

- Closing (both local and remote as applicable)

- Release by trip test from the relay

- Check the operations according to this sequence:

- Open - Springs unloaded

- Open - Springs loaded

- Closed - Springs unloaded

- Closed - Springs loaded

- Check operation of the accessories, if present

- Check operation of reduction gear (if present)

- Check operation of undervoltage release (if present)

- Check operation of opening release (if present)

- Check operation of closing release (if present)

- Check operation of auxiliary contacts of circuit-breaker

(if present)

- Check operation of lock of circuit-breaker in open posi-

tion (with key or padlocks) (if present)

- VAUX: check the presence of auxiliary power supply 24V DC on relay.

8.3.10. Interlock

- Check that the interlock devices have been correctly installed and operate correctly between adjacent and superimposed circuit-

breakers (if present). The operating test cannot be run in the Test or Extracted positions.

8.4. Second level maintenance operations

8.4.1. Preliminary operations:

- open the circuit-breaker and check that the control springs are

unloaded

- in the case of a withdrawable circuit breaker, remove the circuit

breaker from the fixed part before working on it

WARNING: before working on fixed circuit-break-

ers or on fixed part, disconnect the supply to the

power circuit and to the auxiliary circuits and earth

the terminals in a visible manner both on the sup-

ply and on the load side.

8.4.2. General checks and cleaning:

- Check the cleanliness of the apparatus (switching part), removing dust and any traces of excess oil or grease with dry cloths (if

necessary, use non-corrosive detergent)

- For excessive deposits, a dilutant such as Henkel 273471 or the equivalent can be used.

- Check that the rating plates of the apparatus are in place

- Clean the rating plates with dry and clean cloths

- Eliminate any dust, mould, traces of condensation or oxidation also inside the fixed part if the circuit-breaker is a withdrawable version.

- Check that there are no factors such as overheating or cracks that may compromise circuit-breaker insulation

- Check the circuit-breaking couple for damage (for the fixed part, see feature A, fig 39).

- The couple must be silver in colour without trace of erosion or smoke

- Check that there are no foreign bodies in the circuit-breaker cabinet

- Check that the fixing screws are tightened on the fixed side to the control panel (M8 - 25Nm).

Fig. 37

Fig. 38