B2342

Emax VF

26/66

Doc. no.

Model

Apparatus

Scale

Page No

1SDH000909R0001

- Once the connection between the relay and PC has been installed, check that there are no alarm signals from the relay; otherwise,

consult the paragraphs ‘Error Messages’ and/or ‘Troubleshooting’ in this manual.

- In normal operating conditions the trip test and the autotest can be run (depending on the type of relay); for future checks, we advise

inserting the current date in the User Data and/or Tag Name area. These data will be stored inside the relay.

- Remove the Ekip T&P cable adapter from the relay.

8.4.10. Maintenance operations; final checks:

- Refit each part and always reconnect the auxiliary supply.

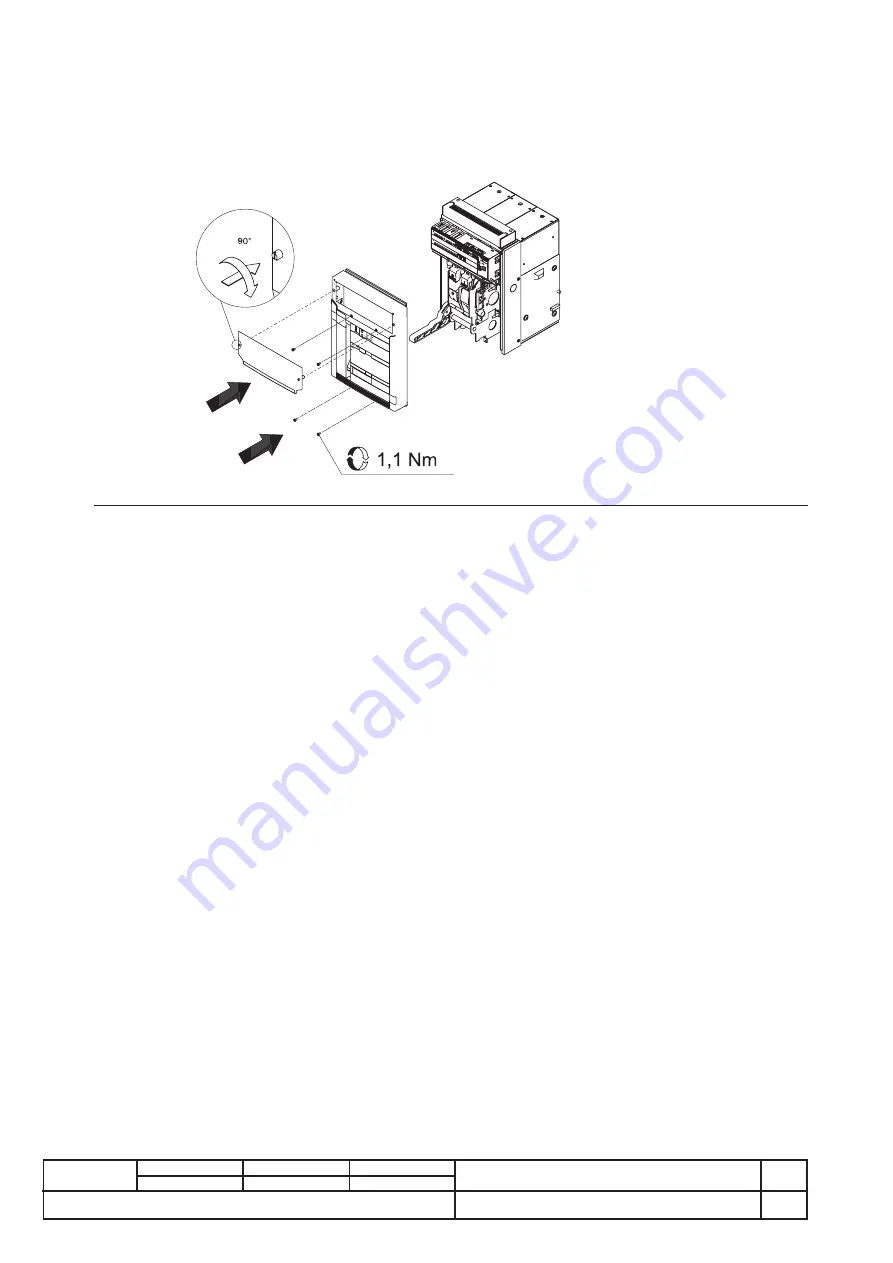

- Refit the cap as indicated in figure 46.

Fig. 46

- Return the movable part to the position TEST-ISOLATED.

- Use the different auxiliaries in turn to run the following 10 operations:

- opening (both local and remote as applicable)

- closing (both local and remote as applicable)

- release by trip test from the relay

- Check the operations according to this sequence:

- Open - Springs unloaded

- Open - Springs loaded

- Closed - Springs unloaded

- Closed - Springs loaded

- Check operation of the accessories, if present

- Check operation of reduction gear (if present)

- Check operation of undervoltage release (if present)

- Check operation of opening release (if present)

- Check operation of closing release (if present)

- Check operation of auxiliary contacts of circuit-breaker (if present)

- Check operation of lock of circuit-breaker in open position (with key or padlocks) (if present)

- VAUX: check the presence of auxiliary power supply 24V DC on relay.

8.4.11. Interlock

Check that the interlock devices have been correctly installed and operate correctly between adjacent and superimposed circuit-

breakers (if present). The operating test cannot be run in the Test or Extracted positions.

8.4.12. Withdrawable

In the withdrawable versions, check the operational efficiency of the insertion and extraction of the circuit-breakers from the fixed part,

performing the movement by means of the operating lever supplied and checking that the shutters for segregating the parts carrying

live voltage are closed after extraction. Check correct operation of the inserted and extracted circuit-breakers lock devices (if present).