C1 3 0 0/A DVA NCE D CI RCU L A R CH A RT R ECOR DE R

| C I/C 1 3 0 0 - EN R E V. C

7

5 Electrical connections

WARNING

• The device is not fitted with a switch therefore a

disconnecting device such as a switch or circuit breaker

conforming to local safety standards must be fitted to the

final installation. It must be fitted in close proximity to

the device, within easy reach of the operator and must be

marked clearly as the disconnection for the device. A fuse

must be fitted in accordance with figure (*).

• Remove all power from the supply, relay and any powered

control circuits and high common mode voltages before

accessing or making any connections.

• Use cable appropriate for the current loads: 3-core cable

rated 3A and 90°C (194°F) minimum, that conforms to

either IEC 60227 or IEC 60245. The terminals accept cables

from 0.8 to 2.5 mm2 (18 to 14 AWG).

• The device conforms to installation category II of IEC

61010.

• All connections to secondary circuits must have basic

insulation.

• After installation there must be no access to live parts, for

example, terminals.

• Terminals for external circuits are for use only with

equipment with no accessible live parts.

• If the indicator is used in a manner not specified by the

company, the protection provided by the equipment may

be impaired.

• All equipment connected to the device’s terminals

must comply with local safety standards (IEC 60950,

EN601010-1).

NOTICE

• Always route signal leads and power cables separately,

preferably in earthed (grounded) metal conduit.

• Use screened cable for signal inputs and relay

connections.

• Replacement of the internal battery (type Varta CR2032

3V lithium cell) must only be carried out by an approved

technician.

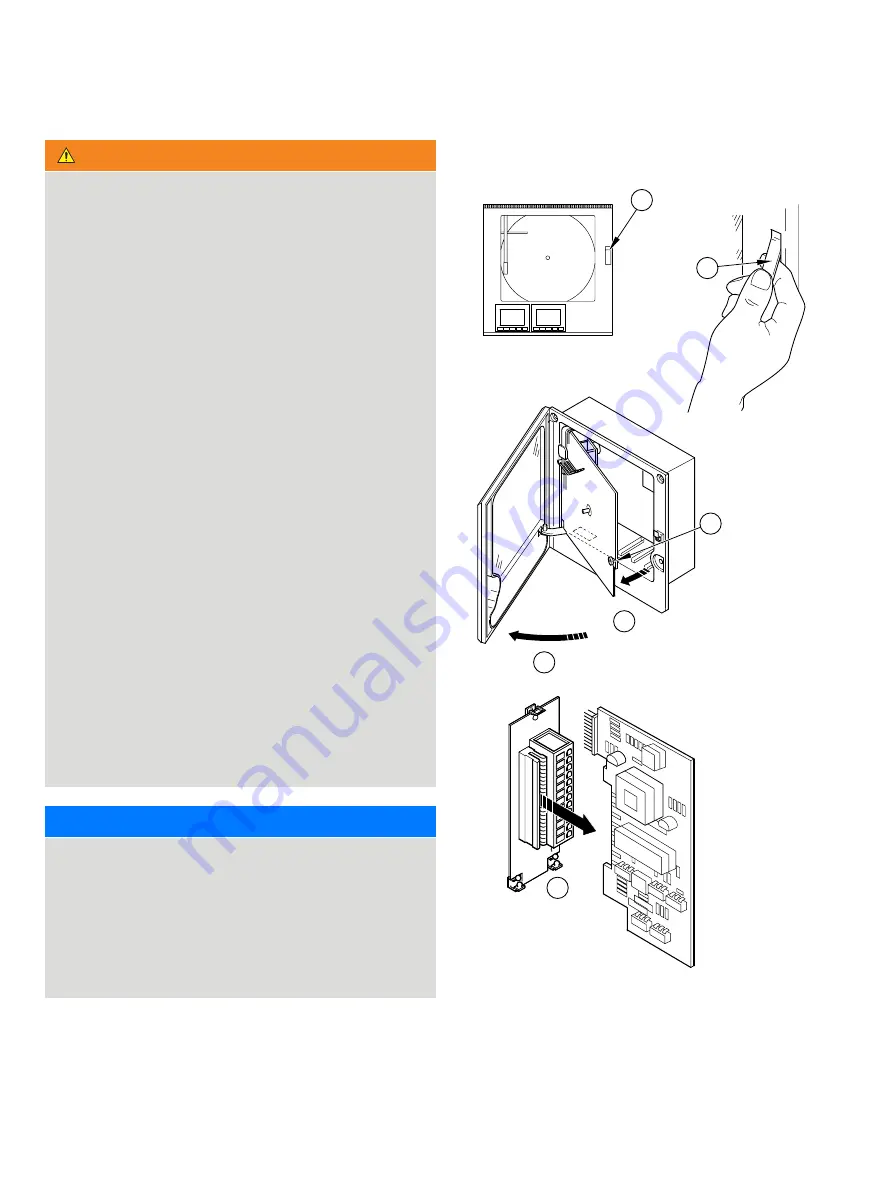

Accessing the terminal connections

Figure 5 Accessing the terminal connections

Push to

release handle

Loosen

captive screw

Swing chart plate forward

...and open the door

Unplug

module

Pull handle

to release

door...

3

6

5

4

2

1