6

3 SETTING UP

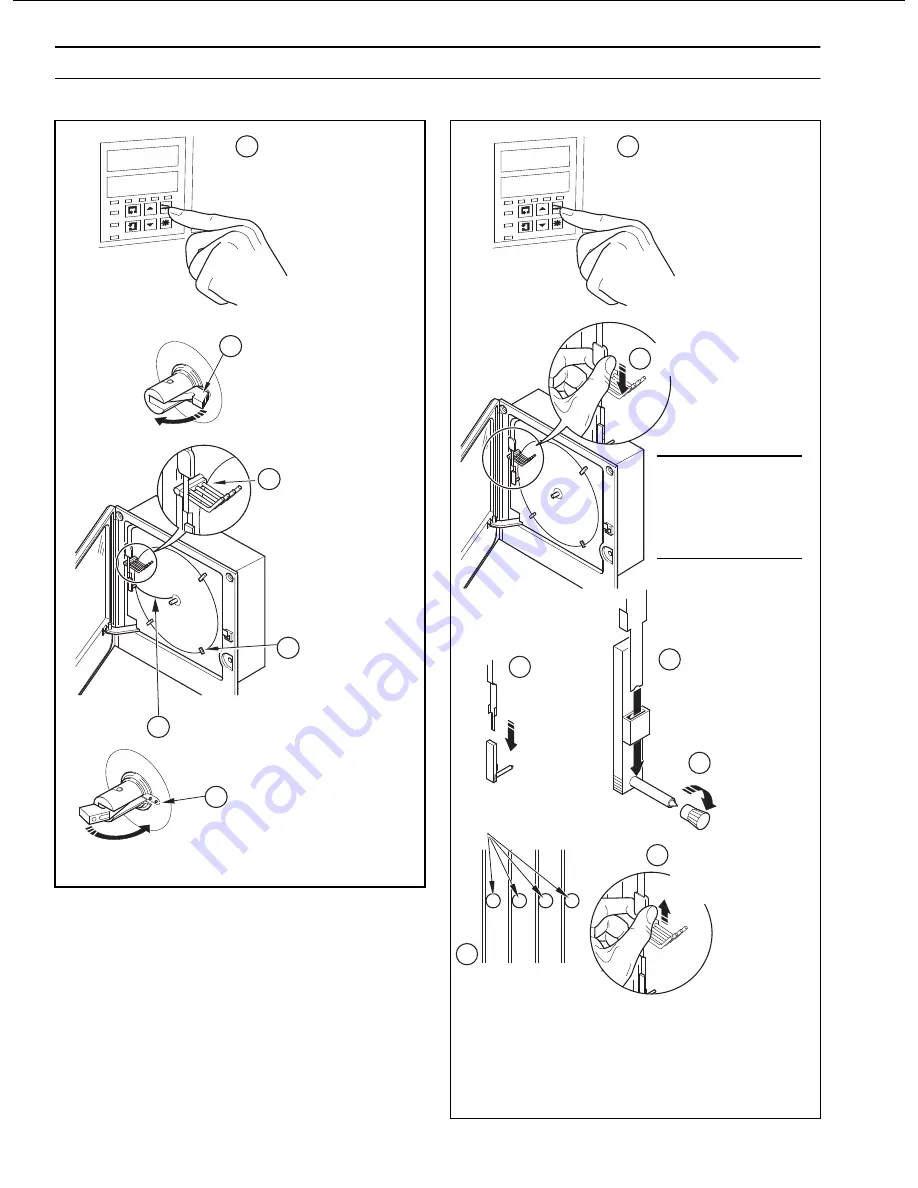

3.2 Fitting the Pen Capsule(s) – Fig. 3.2

Fig. 3.1 Fitting the Chart

Fig. 3.2 Fitting the Pen Capsules

75.0

Lift the chart clamp

and remove the chart

Fit new chart ensuring

that it is beneath the

pen lifter bars

Raise pens

Locate chart

under guides

Rotate chart to align the

time line with the red pen

(see also IM/C1900-OGR Fig. 2.1

or

IM/C1900-OGC Fig. 2.1)

dEGF

Lower the chart clamp and press

down firmly to ensure that the 2

locating pins pierce the paper

1

2

3

4

5

6

3.1 Fitting the Chart – Fig. 3.1

75.0

Raise pens

Remove cap

Fit new pen capsule

ensuring that the arm

locates in the pen

capsule slot

Remove spent

capsule

dEGF

Gently pull the arm

off the bracket

Lifter bars

Ensure that the arm

is positioned above

its lifter bar

Slide pen assembly

onto the appropriate

bracket until it

clips into place.

1

2

3

4

5

6

7

Caution.

Take care not to

bend the arms

during removal and

re-fitting as pen

clashing may result.

Summary of Contents for C1900 Series

Page 11: ...Sales Software Service...