Retort Control in the Food Industry using the C360

AG/RCP-007_2

3

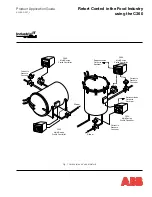

Fig. 2 Loading a Vertical Retort

The Application

Much of the food consumed each year is preserved by packaging it in hermetically-

sealed containers in a process known as

canning

.

One of the most important steps in the canning of foods is 'thermal processing', more

commonly referred to as the

retorting

operation. In this operation, strict specifications,

concerning both time and temperature, must be adhered to and repeated, batch after

batch, to obtain sterile product and uniform quality.

Processing is done in batches using a cylindrical, pressurized vessel called a

retort

.

Retorts are classified as either vertical or horizontal, depending on the position of

its long axis. A vertical retort is loaded from the top whereas a horizontal retort is

loaded from one end.

In either retort type, the canned product is cooked by one of two processes:

▲

Steam cooking for product stored in metal containers

▲

Water cooking for product stored in glass jars

Steam cooking is done in a steam atmosphere devoid of air and water cooking is

done in steam heated water.

A1

A2

L

R

ST

M

108.6

108.6

C360

Multi-Recipe

Profile Controller

Current to

Pressure

Converter

Retransmission

Output to

Recorder