GETTING STARTED

The COMMANDER 500 can be configured and made ready for operation in three easy

steps. This 'Getting Started' guide provides an overview of these steps and, where

necessary, refers to the relevant section of the manual.

Step 1 – Decide on the Application Template and the

Output Configuration required

Step 2 – Connect the process inputs and outputs

Step 3 – Power up the instrument, set the template number and the output

configuration details

Your COMMANDER 500 is now ready for operation

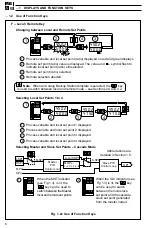

Step 1 – Application Template and Output Configuration

•

Choose the Template which best suits your application from the list in Table A,

located on the rear fold-out.

•

Choose the Control Output Type required from the list of options in Table B on the

rear foldout.

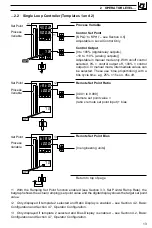

Step 2 – Electrical Connections

Using the labels on the back of the instrument as a guide, connect the process inputs,

outputs and power supplies. Refer to Section 5.2 of this manual (Electrical Installation)

for more information.

Continued…