—

TRANSFORMER COMPONENTS

Temperature monitoring device

Comem DTI and Comem eDTI

Instruction manual

Content

1. Safety

1.1 Safety instructions 3

1.2 Specified applications 4

1.3 Safety notes on the equipment operation

4

2.

Comem DTI and eDTI

5

2.1 Operating principle

5

2.2 Installation 6

2.3 Connection of the temperature sensors 7

2.4 Output relays

7

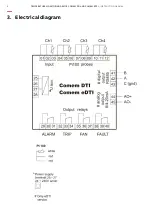

3.

Electrical diagram

8

4.

Wiring connection

9

5.

Front panel description

10