84

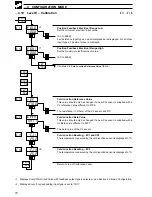

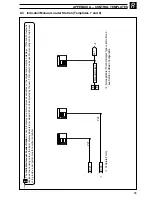

…APPENDIX A – CONTROL TEMPLATES

CSPt

I/P2

I/P1

di.1

PV

Process V

ariable

PID

Controller

Low Signal Select

(Alarm A1)

Local/

Remote

Select

•1

•2

•1

T

emplate 5 only

.

Alarm

A1 trip value can be set to give the desired low signal detection

•2

T

emplate 6 only

.

Master Output

Digital Select

Manual Output

L

LR

ao1

OP1

Local Set Point

PV–

CSPt

A2.3

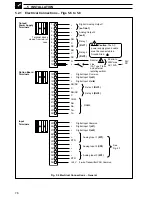

Analog Backup (Templates 5 and 6)

The

Analog Backup

provides a backup for a master controller. In normal operation (remote control mode selected) the COMMANDER 350’s current

output follows the master controller’s output value. A fault in the master system can be identified either by detecting a low s

ignal on the master output

(template 5) or via a digital signal (template 6). When a fault is detected the COMMANDER 350 switches into local control mode

and the process is

controlled by the PID output of the COMMANDER 350. The COMMANDER 350 PID algorithm continually tracks the master output value t

o ensure

bumpless transfer from remote to local mode operation. When the master signal is restored or the digital input returns to its n

ormal state the COMMANDER

350 switches back to remote control mode (i.e. COMMANDER 350 output = master output).

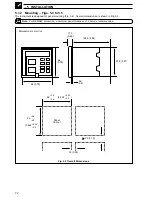

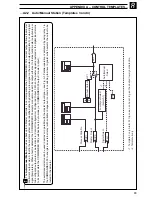

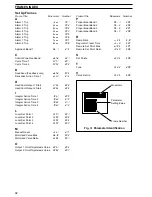

The analog backup station can be used in series or in parallel with the master output signal. (See Fig. A1). Parallel operation

is achieved by using relay

1 in the COMMANDER 350 to energize an external relay (with suitable changeover contacts for switching low level signals) which

selects the output to be

routed to the actuator.