PME120-AI / PME120-AN (Contrac)

ELECTRICAL ROTARY ACTUATOR | SEI/PME120-EN REV. A

5

2

Introduction

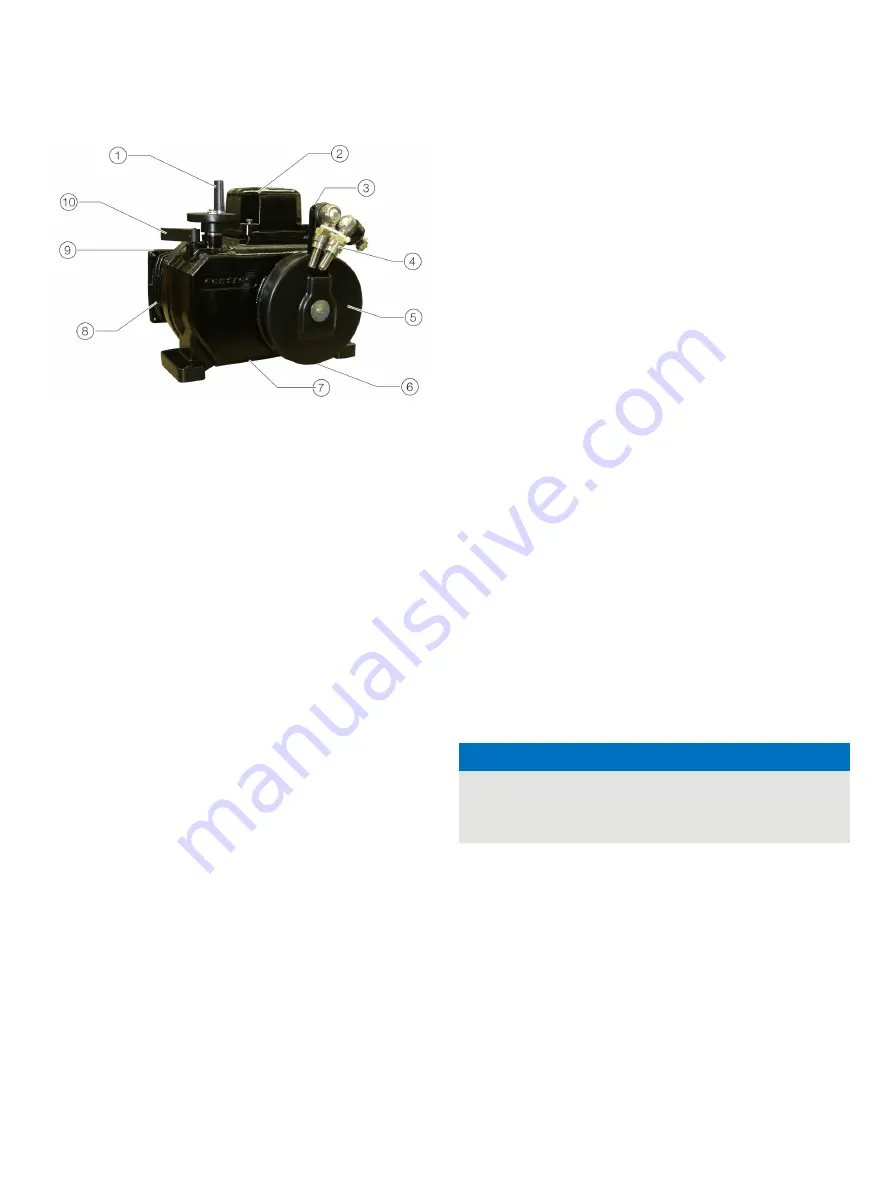

1

Handwheel crank

2

Plug

3

Lever

4

Ball-and-socket joint

5

Lever cover

6

Adjustable stops

(under the lever cover)

7

Gear housing

8

Control motor

9

Cover (for PME120-AI incl.

electronic unit)

j

Handwheel release

Figure 1: PME120 (illustrations may differ from actual installation)

This service instruction refers to the ABB rotary actuators

PME120-AI (with integrated electronic unit) and PME120-AN (for

separate electronic unit).

It amends and deepens the routine maintenance description in

the standard instruction, which we strongly recommend being

also available for all maintenance work.

Safety and precautions

When mounting the actuator in areas which may be accessed by

unauthorized persons, take the required protective measures.

• The actuators perform movements for positioning vanes and

valves. Handle properly and with care. Otherwise, a hazard of

bruise injuries may arise.

• When changing the oil of the actuator, thoroughly remove

any oil that may have run down on the floor during the

procedure to avoid accidents.

• Dispose of the waste oil in compliance with the respective

local regulations. Make sure that no waste oil reaches the

water cycle.

• Only qualified specialists who have been trained for these

tasks are authorized to mount and adjust the control

actuator, and to make the electrical connection.

• When working on the actuator itself or the electronics always

observe the locally valid accident prevention regulations and

the regulations concerning the construction of technical

installations.

• Use the eye bolt at the actuator to lift or lower it. Only load it

vertically. Do not lift or lower the actuator when it is mounted

on a valve or similar final control element.

• Switch-off the voltage supply; make sure that unintentional

switching on is not possible.

• Make sure that switching off the power supply does not

affect the plant process.

• Make sure that the final control element is not exposed to

process forces.

Tools

NOTICE

Damage to the device due to improper tools!

Using improper tools may damage the actuator or its

components.

• Only use proper tools for maintenance work.

Note

• Maintenance at Contrac actuators requires tools which are

usually available in a workshop. Please consider that all

dimensions are based on the metrical system. This applies

also for the wrench sizes, threads etc.

• Use appropriate sleeves for the installation of the sealing

rings (see

Installation

on page 13 for details).