15

12. Maintenance

Linear actuators of the RSD... series feature a robust design. As a result, they are highly reliable and

require only little maintenance. The maintenance intervals depend upon the effective load and are

therefore not specified here.

The built-in microprocessor evaluates the actual load factors (e.g. torques, temperatures, etc.) and de-

rives the remaining operating time until the next routine maintenance is required. Use the configuration

program for viewing this information.

12.1 Motor and Gears

All maintenance work must be carried out by qualified specialists who have been trained for this task.

As a rule, perform the following routine maintenance works:

-

Check the shafts and gears

-

Check the drive rod surface for damage

-

Check the motor pinion gear and the respective mating gear.

-

Replace the motor’s rotary shaft seal and ball bearings.

-

Check the position sensor.

-

Change the oil; then make a visual check and check for proper operation.

12.2 Adjusting the Brake

Note that the actuator setting may be changed accidentally by the repelling power of the valve when the

brake is released!

In automatic mode the brake is permanently released. Therefore, it is not exposed to wear and does

not require any re-adjustment.

12.3 Replacing the Position Sensor

12.3.1

Dismounting

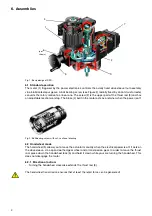

Figure 13:

-

drive actuator into 50% position (refered to rated actuator stroke)

-

delete the current position settings by pressing the 2 drive buttons on the LCP for at least 5 sec

-

switch-off the voltage supply

-

disconnect electrically

-

remove male connector

-

loosen both fastening screws (1) of position sensor (fig. ) and take sensor out

-

detach plug from sensor pcb

connection plug

male connector

d0150rxa