9

9. Mounting

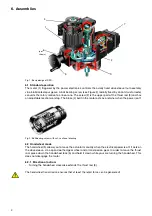

9.1 Actuator check

Prior to mounting the actuator please verify if the device has been delivered in the configuration spec-

ified in your order and if it is suitable for the intended purpose. Check:

-

if the positioning travel is sufficient for the valve stroke

-

if it is filled with the proper oil type, see section 8.2 or oil label on actuator for details.

-

if the proper oil quantity has been filled in

Fasten the separately delivered venting screw in the highest bore (depending on the mounting orienta-

tion).

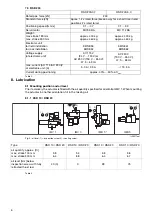

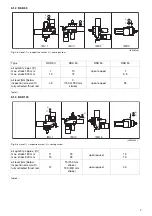

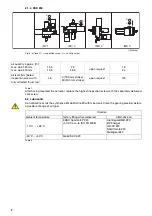

9.2 Mounting orientation

All mounting orientations seen in Figure 3 to 6 are permissible. To facilitate mounting and maintenance,

however, it is recommended to use orientation IMV 1.

9.3 Mounting to the final control element

-

Make sure that the actuator is accessible from all sides to ensure convenient handwheel operation,

electrical connection, and replacement of assemblies.

-

Avoid direct exposure to rain, snow and other environmental influences. Select the mounting site

accordingly.

-

When mounting the actuator close to heat sources use an insulating layer or shielding.

9.3.1 Valve design requirements

-

Consider end position forces of up to 2.5 x the rated force when designing/selecting the valve.

9.4 Adapting the actuator stroke to the valve stroke

In factory, the stroke

+3...5 mm

specified on the actuator ID label is set. If it should be necessary to re-

adjust the stroke (observe the minimum and maximum stroke specified in section “Technical Data“)

proceed as described below:

-

When mounting the actuator in an orientation other than IMV 1, refill oil according to the specifica-

tions.

-

Fully extend the thrust rod using the handwheel until the internal stop is in contact with the drive

sleeve.

-

Undo the screws of the thrust rod hood cover and remove the cover.

-

Undo the screw plug in the thrust rod hood.

-

The two Allen screws can now be accessed through the opening. Undo the screws.

-

Retract the thrust rod using the handwheel until the actuator stroke matches the specified valve

stroke.

-

Turn the internal stop (slotted ring nut) clockwise using a screw driver, until the stop gets in contact

with the drive sleeve. Then re-turn acround 3 times.

-

Refasten the two Allen screws with the specified torque

RSD 10 / RSD 20:

26 Nm

RSD 50:

26 Nm

RSD 100:

40 Nm

RSD 200:

69 Nm

-

Fasten the cover of the thrust rod hood, refasten the lateral screw plug, fill in the oil.