I N S T A L L A T I O N

21

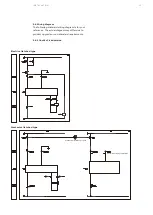

5.7 Assembly and connections

5.7.1 Fixed version

Before carrying out any installation operations

:

•

Test all the power terminals to check that they

are not supplied with voltage. Only use high

voltage testing equipment approved for checking

the voltage on the power terminals. Do not

attempt to measure the high voltage (above

600 V) with a volt-ohm/meter

•

Check all the control and secondary circuit

terminals with a voltmeter to ensure that all the

control and secondary input voltage sources have

been turned off

•

After de-energizing but before proceeding with

any work on the apparatus, confirm that power

terminals have been grounded and are in safe

conditions

•

Carry out all the operations for turning off the

voltage and grounding according to the

established safety procedures

General inspections

•

Clean the insulation surface with a rough dry cloth

•

Check that the contact surfaces of the connections

are flat, and are free of any burrs, traces of

oxidation or deformation caused by drilling or

impacts received

•

Select the cross-section of the conductors

according to the service current and the short-

circuit current of the installation

•

Prepare special support insulators near the

terminals of the contactor, sized according to

the electrodynamic forces caused by the short-

circuit current of the installation and avoid

stressing the connections laterally

ConVac installation and connection of the

primary circuit

•

Fixed conductors could be installed directly on

the support frame, according to the overall

dimensions in 5.5.1

•

put the connections in contact with the contactor

terminals, taking care to avoid mechanical stresses

produced, for example, by the conductor busbars

on the terminals themselves

•

Interpose a spring and a flat washer between the

head of the bolt and the connection. The use of

bolts according to DIN class 8.8 Standards is

recommended, also referring to what is indicated

in the table

•

In the case of cable connections, strictly follow

the manufacturer’s instructions for making the

terminals

•

Grounding of fixed ConVac is realized by

grounding bolt, accompanied by a grounding

sign as Fig 5a shows. An area of about 30 mm

around the grounding bolt should be kept clean,

reapply Vaseline lubricant to cover the joint after

installation. Use cables with a suitable cross-

section according to related standards

Connection of the auxiliary circuits

•

The cables to be used for connection of the

auxiliary circuits must no less than the cable

used inside the contactor, and be insulated for

2 kV/1 min test

•

Please refer to 5.6.1 for the wiring of auxiliary

circuit, make sure the cables are reliably

connected to the contactor

•

Outside, the wires must run through metallic

pipes or ducts suitably grounded

5.7.2

Withdrawable version

•

The withdrawable contactors are used in the

UniGear ZS1 or other switchgear with the same

dimension

•

Confirm that the contact fingers are clean, and

no deformation due to shipping or crash

•

The auxiliary circuit connections of withdrawable

contactor are derived via the plug. The wiring

diagram could refer to chapter 5.6.2

•

The cables to be used for connection of the

auxiliary circuits must no less than the cable used

inside the contactor, and be tested for 2 kV/ 1 min

•

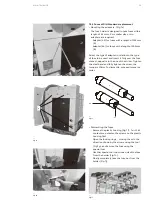

three current-limiting fuses (prepared by

customers) with high breaking capacity connected

in series with the contactor, with dimensions

according to

- DIN 43625 Standard with maximum length e

=442 mm

—

Fig 5c

- BS 2692 Standard with maximum distance L

=454 mm

5.7.3 Interlock of withdrawable version

•

Electrical lock which prevents the contactor from

being closed when the truck is not in the racked-in

and isolated positions

•

Mechanical lock which prevents the contactor

from being racked-in and out when it is closed

and closing of the contactor when the truck is

not in the racked-in and isolated positions

•

Electrical lock which prevents closing of the

contactor when any one fuse is missing or blown

•

Lock which prevents insertion of the plug-socket

and therefore apparatus (Fig 5c,interlock of

contactors with different rated current)

Type

Closing

Opening

Description

Inputs

Description

Inputs

5.8 Operation of the Contactors

5.8.1 Two operation modes for ConVac contactor:

electrical latching and mechanical latching

Electrical latching

Closing takes place by supplying auxiliary

power to the feeder. The minimum duration

of closing impulse signal is 300 ms (a short

impulse signal will make the contactor

immediately opens after the closing

operation)

Fixed version

:

XDB1:1 - XDB1:3

Withdrawable version

:

XDB:31 - XDB:30

opening occurs when the auxiliary power

is interrupted either intentionally

Fixed version: XDB1:1 - XDB1:3

Withdrawable version: XDB:31 - XDB:30

Mechanical latching

Closing takes place when the opening coil

is Supplied. The minimum duration of

closing impulse signal is 300 ms

Fixed version

:

XDB1:1 - XDB1:3

Withdrawable version

:

XDB:4 - XDB:14

Opening takes place when the opening

coil is supplied. The minimum duration of

opening impulse signal is 300 ms

Fixed version: XDB3:1 - XDB3:3

Withdrawable version: XDB:31 - XDB:30

—

Fig 5b

5b-2

5b-1

5b-3

•

Locking electromagnet on the truck to prevent

racking-in/out when dis-energised.

(

Fig 5b-1

)

•

Mechanical lock which prevents contactor from

racking-in if the enclosure door is not closed

(

Fig 5b-2

)

•

Mechanical interlock with earthing switch placed

on the enclosure

:

with earthing switch closed

the contactor cannot be racked-in and with the

contactor racked-in or in intermediate positions

between racked-in and isolated, it is not possible

to close the earthing switch

(

Fig 5b-3

)

Summary of Contents for ConVac

Page 2: ......

Page 35: ...安装 21 ...