13

Electromagnetic Flowmeter

COPA-XE / MAG-XE

Submenu/Parameter

Entry Type

Comments

from table/numeric

Exit the submenu

ml/s, ml/min, ml/h, Ml/h, Ml/min, Ml/day, lbs/s,lbs/min, lbs/h,

uton/min, uton/h, uton/day, l/s, l/min,l/h, hl/s, hl/min, hl/h,

m3/s, m3/min, m3/h, igps, igpm, igph, mgd, gpm, gph,

bbl/s, bbl/min, bbl/h, bls/day, bls/min, bls/h, kg/s, kg/min, kg/h,

t/s, t/min, t/h, g/s, g/min, g/h, kgal/s, gkal/min, kgal/h

ml, l, hl, m3, igal, gal, mgal, bbl, bls, kg, t, g, Ml, lb, uton, kgal

If the desire units are not included in the table, it is possible to

configure a user defined unit, based on liters. The value shown,

3785.41, is the conversion factor for kgal (Factory setting).

Four character name for the user configured unit.

Programmable unit for mass (with density) or volumetric flow

(without density)

from table/numeric

Exit the submenu

All detected errors (Errors 0-9, A, B, C) are stored.

The error register can be cleared by pressing ENTER.

Limit alarm, range 0 - 130 % of the flow range setting.

Can be set in steps of 1 %, switching hysteresis 1 %.

Limit alarm, range 0 - 130 % of the flow range setting.

Can be set in steps of 1 %, switching hysteresis 1 %.

from table

Contact output, Terminal P7/G2 selections (for Profibus terminals

Ux/P7): General alarm

)

, empty pipe

1)

, F/R signal, no function,

MAX-Alarm

1)

, MIN-Alarm

1)

,MAX/MIN-Alarm

1)

1) Contact input can be configured to “Open or Close”.

Contact input, Terminal X1/G2 selections: External zero return,

external totalizer reset, external totalizer stop, no function. For

HART-Protocol the external totalizer stop function is not available.

The contact input is not available for Profibus.

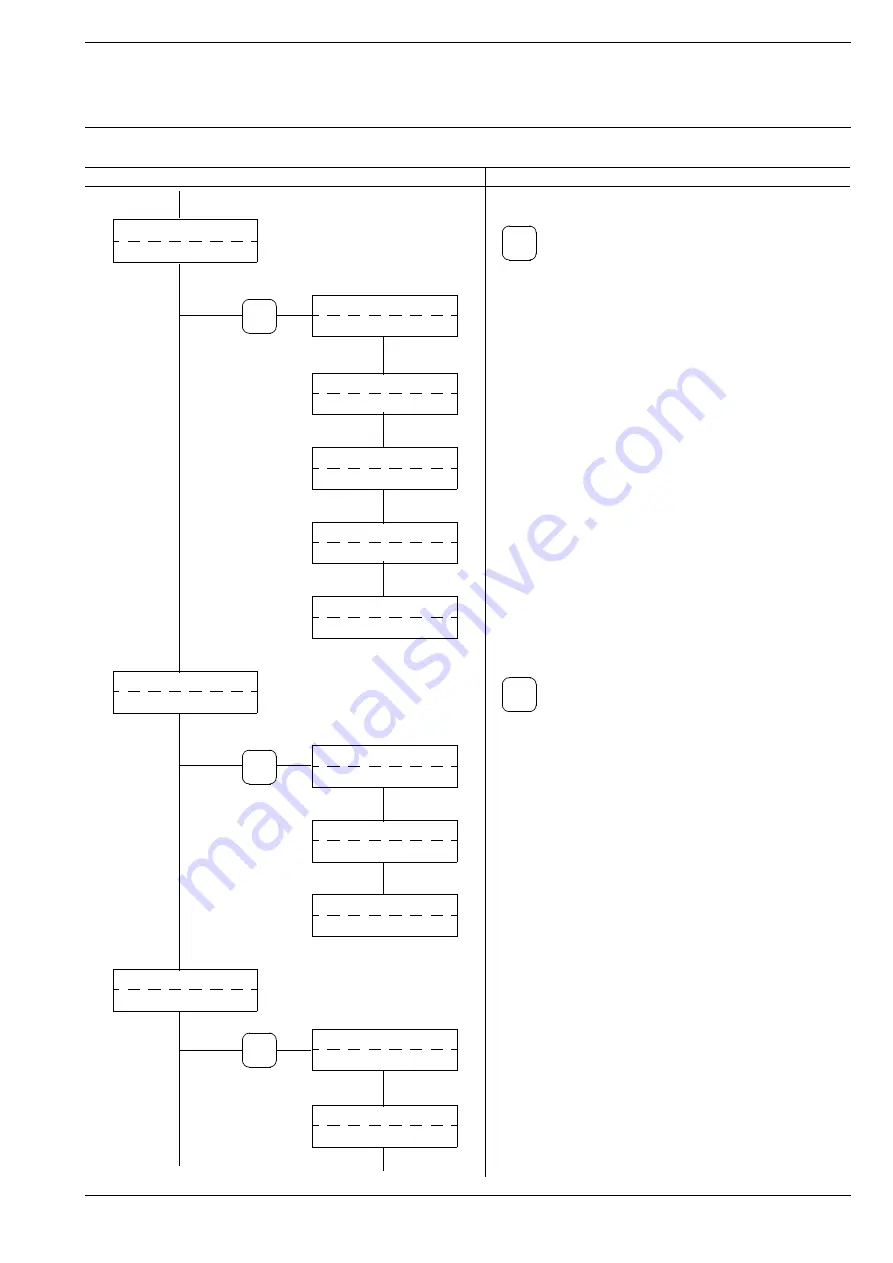

Submenu

Units

C/CE

ENTER

Units

Qmax

l/s

Units Totalizer

m3

Units Factor

3785.41 Liter

Unit Name

kgal

/s

/min

/h

Prog. Units

w/o Density

Submenu

Alarm

C/CE

ENTER

Error Register

0 ... 3 ...

Max-Alarm

130 %

Min-Alarm

10 %

Submenu

Prog. In-/Output

ENTER

Terminals P7/G2

General Alarm

Terminals X1/G2

Ext. Zero Return

Summary of Contents for COPA-XE

Page 4: ......