41-116.1A

4

reclosing will be initiated immediately after a trip by

the CO contact, the time of the opening of the con-

tacts should be a minimum. This condition is

obtained by loosening the stationary contact mount-

ing screw, removing the contact plate and then

replacing the plate with the bent end resting against

the contact spring.

For double trip relays, the upper stationary contact is

adjusted such that the contact spring rests solidly

against the back stop. The lower stationary contact is

then adjusted such that both stationary contact make

contact simultaneously with their respective moving

contact.

4.2. INDICATING CONTACTOR SWITCH (ICS)

There are no settings to make on the indicating con-

tactor switch (ICS).

4.3. INDICATING INSTANTANEOUS TRIP (IIT)

The proper tap must be selected and the core screw

must be adjusted to the value of pick-up current

desired.

The nameplate data will furnish the actual current

range that may be obtained from the ITT unit. It is

recommended that the IIT be set on the higher tap

where there is a choice of tap settings. For example,

for a 20 ampere setting use the 20 to 50 tap rather

than the 6 to 20 tap.

4.4. VOLTAGE UNIT (V)

The voltage unit

spring calibration is set to close its

contact when the applied voltage is reduced to 80

volts. The voltage unit can be set to close its contacts

from 80 volts to 100 volts

by adjusting the resistor

located at the top left of the voltage unit. The spiral

spring is not disturbed when making any setting other

than the calibrated setting of 80 volts.

5. INSTALLATION

The relays should be mounted on switchboard pan-

els or their equivalent in a location free from dirt,

moisture, excessive vibration and heat. Mount the

relay vertically by means of the four mounting holes

on the flange for the semi-flush type FT case. The

mounting screws may be utilized for grounding the

relay. External toothed washers are provided for use

in the locations shown on the outline and drilling plan

to facilitate making a good electrical connection

between the relay case, its mounting screws and the

relay panel. Ground wires should be affixed to the

mounting screws as required for poorly grounded or

insulated panels. Other electrical connections may

be made directly to the terminals by means of screws

for steel panel mounting.

For detail information on the FT case refer to IL

41-076 for semi-flush mounting.

6. ADJUSTMENTS AND MAINTENANCE

The proper adjustments to insure correct operation of

this relay have been made at the factory. Upon

receipt of the relay, no customer adjustments, other

than those covered under “SETTINGS”, should be

required.

The Indicating Instantaneous Trip unit (IIT) used in

some relays requires a much higher current for trip-

ping than is required by the other units. For this rea-

son, the junction of the CO unit coil and the IIT unit

coil is brought out to switch jaw no. 3 (whenever it is

available) to permit the testing of these units sepa-

rately.

When applying current in excess of 50 amperes

to test the IIT, the current should not be left on

while adjusting it to the trip level. Instead, apply

the current in short bursts, not more than 2 sec-

onds long, to check for tripping. Make adjust-

ments in the current control while the current is

off.

High currents left on for excessive time periods

can result in the softening and possible melting

of insulation the interconnecting wires.

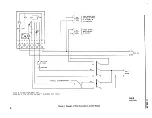

6.1. OPERATIONAL CHECK

The following check is recommended to insure that

the relay is in proper working order. (See Figure 9.)

6.1.1. Overcurrent Unit (CO)

The directional unit contacts must be in the closed

position and the “T” unit picked up when checking the

operation of the overcurrent unit.

A. Contact

1) By turning the time dial, move the moving

!

CAUTION