41-116K

7

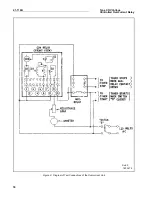

Type COV Voltage

Controlled Overcurrent Relay

6.1.4. Voltage Unit (V)

A. Contact Gap

The gap between the stationary contact and

moving contact with the relay in a de-energized

position should be approximately .020”.

B. Sensitivity

The contacts should close when voltage is

reduced to approximately 90 volts. The voltage

unit should be energized for one hour before

checking the sensitivity.

6.2

ROUTINE MAINTENANCE

All relays should be inspected periodically and the

time of operation should be checked at least once

every year or at such other time intervals as may be

dictated by experience to be suitable to the particular

application. Phantom loads should not be used in

testing induction-type relays because of the resulting

distorted current wave form which produces an error

in timing.

All contacts should be periodically cleaned. A contact

burnisher Style 182A836H01 is recommended for

this purpose. The use of abrasive material for clean-

ing contacts is not recommended, because of the

danger of embedding small particles in the face of

the soft silver and thus impairing the contact.

6.3

CALIBRATION

Use the following procedure for calibrating the relay if

the relay has been taken apart for repairs or the

adjustments have been disturbed. This procedure

should not be used unless it is apparent that the relay

is not in proper working order. (See “Acceptance

Check”).

6.3.1. Overcurrent Unit (CO)

A. Contact

1) By turning the time dial, move the moving

contacts until they deflect the stationary contact

to a position where the stationary contact is rest-

ing against its backstop. The index mark located

on the movement frame should coincide with the

“O” mark on the time dial. For double trip relays,

the follow on the stationary contacts should be

approximately 1/64”.

2) For relays identified with a “T”, located at

lower left of stationary contact block, the index

mark on the movement frame will coincide with

the “O” mark on the time dial when the stationary

contact has moved through approximately one-

half of its normal deflection. Therefore, with the

stationary contact resting against the backstop,

the index mark is offset to the right of the “O”

mark by approximately .020”. The placement of

the various time dial positions in line with the

index mark will give operating times as shown on

the respective time-current curves. For double

trip relays, the follow on the stationary contacts

should be approximately 1/32”.

B. Minimum Trip Current

The adjustment of the spring tension in setting

the minimum trip current value of the relay is

most conveniently made with the damping mag-

net removed.

With the time dial set on “O”, wind up the spiral

spring by means of the spring adjuster until approxi-

mately 6-3/4 convolutions show.

Set the relay on the minimum tap setting, the time

dial to position 6.

Adjust the control spring tension so that the moving

contact will leave the backstop at tap value current

+1.0% and will return to the backstop at tap value

current -1.0%.

C. Time Curve Calibration

Install the permanent magnet

Apply the indicated current per Table 1 for the perma-

nent magnet adjustment (e.g., COV-8, 2 times tap

value) and measure the operating time. Adjust the

permanent magnet keeper until the operating time

corresponds to the value of Table 1.

For type COV-11 relay only, the 1.30 times tap

value operating time from the number 6 time dial

position is 54.9

±

5% seconds. It is important that the

1.30 times tap value current be maintained accu-

rately. The maintaining of this current accurately is

necessary because of the steepness of the slope of

the time-current characteristic (Figure 7, page 16). A

1% variation in the 1.30 times tap value current

(including measuring instrument deviation) will

change the nominal operating time by approximately

4%. If the operating time at 1.3 times tap value is not

within these limits, a minor adjustment of the control

spring will give the correct operating time without any

undue effect on the minimum pick-up of the relay.

This check is to be made after the 2 times tap value

adjustment has been completed.