—

2 Receiving, handling and storage

2.1 Introduction

This chapter describes the procedures for the

receipt, handling and storage of panels and is

intended to support the customer in the verification

of receipt and in the protection of the products

before installation.

2.2 Receiving

For transportation purposes the panel are usually

packed and shipped in multiple sections, each

comprising up to a maximum of seven

compartments (refer to the layout of the order

for the exact composition of the sections).

With the panel are shipped the materials necessary

accessories for mounting and for installation,

except for the foundation beams that are normally

installed by the customer.

Switches and related accessories are packed and

shipped separately.

Upon receipt of:

•

Make sure that the packaging is intact and

free from damage during shipping. If not

noted on the delivery note "PACKAGE DAMAGED,

THE POSSIBILITY OF DAMAGES TO THE

MATERIALS CONTAINED" doing counter sign

the note to the carrier and immediately warning

the ABB sales office about the damage occurred

in transit. Keep the damaged material for the

carrier's inspection. Do not proceed if you do

not open the package in the presence of the

carrier

•

In the absence of any obvious damage remove

the packaging and check that you have every

item shown on the waybill

•

Check there is no damage to the products

•

In case of lack of materials or damage to

contact ABB

2.3 Handling

Warning

Heavy weight

Can cause death, serious injury or

property damage.

Obtain services of a qualified rigger

prior to hoisting the circuit breaker to

assure adequate safety margins in

hoisting equipment and procedures to

avoid damages.

6

DCGear

P R O D U C T M A N U A L

—

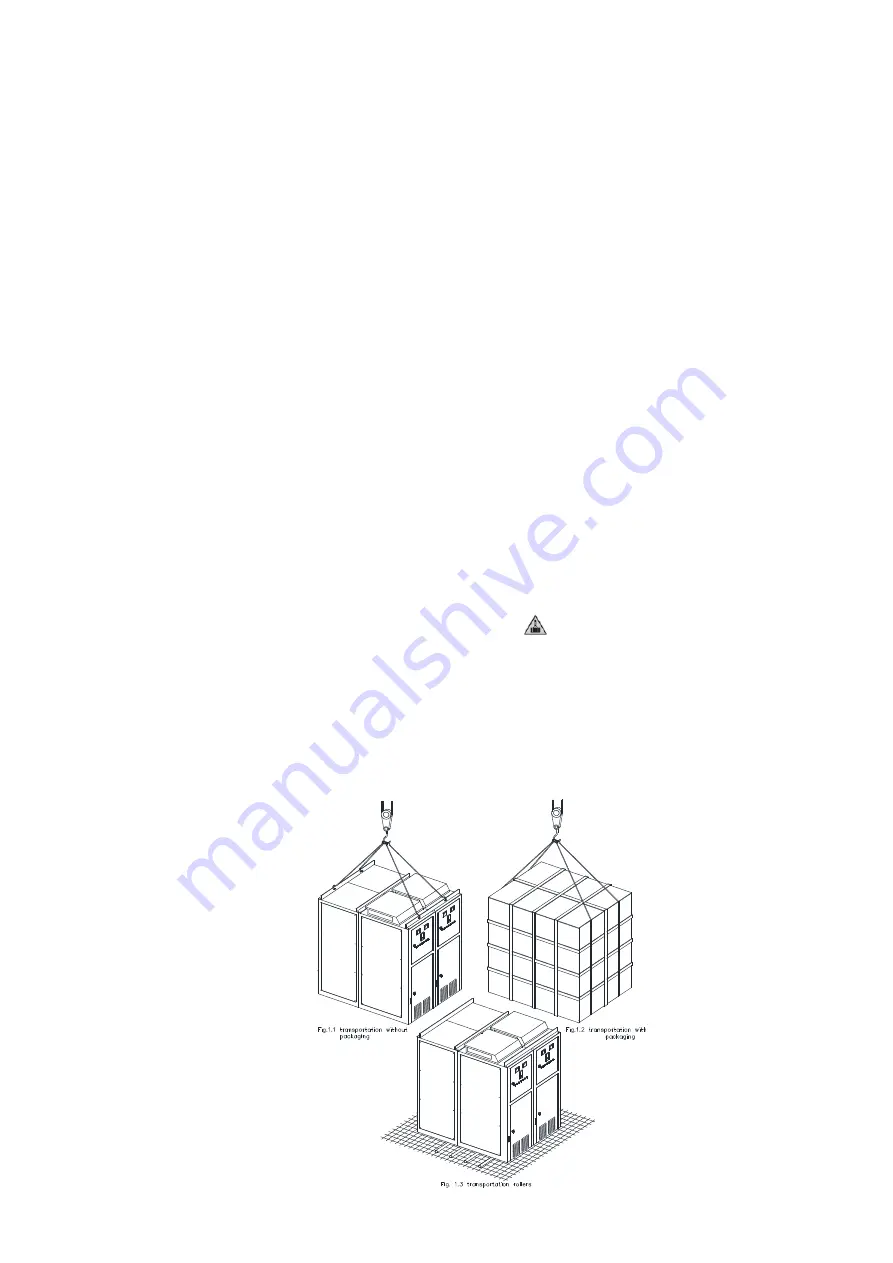

Fig.1 Handling systems

The handling and lifting DCGear panel, after

receiving them, must be done with care and

avoid subjecting the same to abnormal stress,

violent shocks, etc..

The lifting of the panel, still packed, must be

performed with the use of a crane and cables

of adequate section appropriately positioned

(fig.1.1). The weights of the individual conveyor

sections are indicated on the waybill.

The lifting of the panel without packaging should,

possibly, be performed with the use of a crane

and of appropriate cables passed through the

holes provided on the lifting crosspieces (fig.1.2).

When a crane is not available, the panel can be

moved with the use of suitably spaced rollers

positioned under the base (fig. 1.3).

•

The supporting surface of the rollers is flat

•

The rollers are parallel to the front of the panel

•

The amount of rollers is adequate to prevent

deformation of the structure

Avoid using forklift trucks to transport that could

cause localized deformation and permanent

structure of the panel.

2.4 Storage

Wherever possible, the panel must be installed

immediately in its final position.

In the event that it is necessary to provide a

storage for some time prior to installation, it is

advisable to store the equipment in its original

packaging.

2.4.1 Environmental conditions of storage

2.4.1.1 Storage in original packaging

If possible store the panel in their original

packaging.

Packing in wooden crates or cardboard.

Store in an environment protected from the

weather, covered, well-ventilated area with

temperatures between 0°C and +40°C, with a

maximum relative humidity of 60% with occasional

spikes up to 90%, without rapid changes in

temperature, order to avoid condensation.

Maximum storage time: four months.

Packed with case in phenolic plywood and

laminated barrier.

Although it is possible a storage outdoor for a

short period, it is advisable to store under a roof

with temperatures between-5°C and+ 55°C.

This type of packaging allows storage of up to

a year without need for special controls or

maintenance.

2.4.1.2 Storage off from its original packaging

Store this equipment in a confined space, clean,

dry and free from dust and corrosive atmospheric

agents. The panel must be carefully covered and

protected with a polyethylene film of minimum

thickness 0.2 mm. The temperature should be

between -20°C to+ 50°C. To avoid condensation

and corrosion, the environment needs to be

heated and capable of ensuring the absence of

sudden and severe temperature changes.

—

Fig.1