3

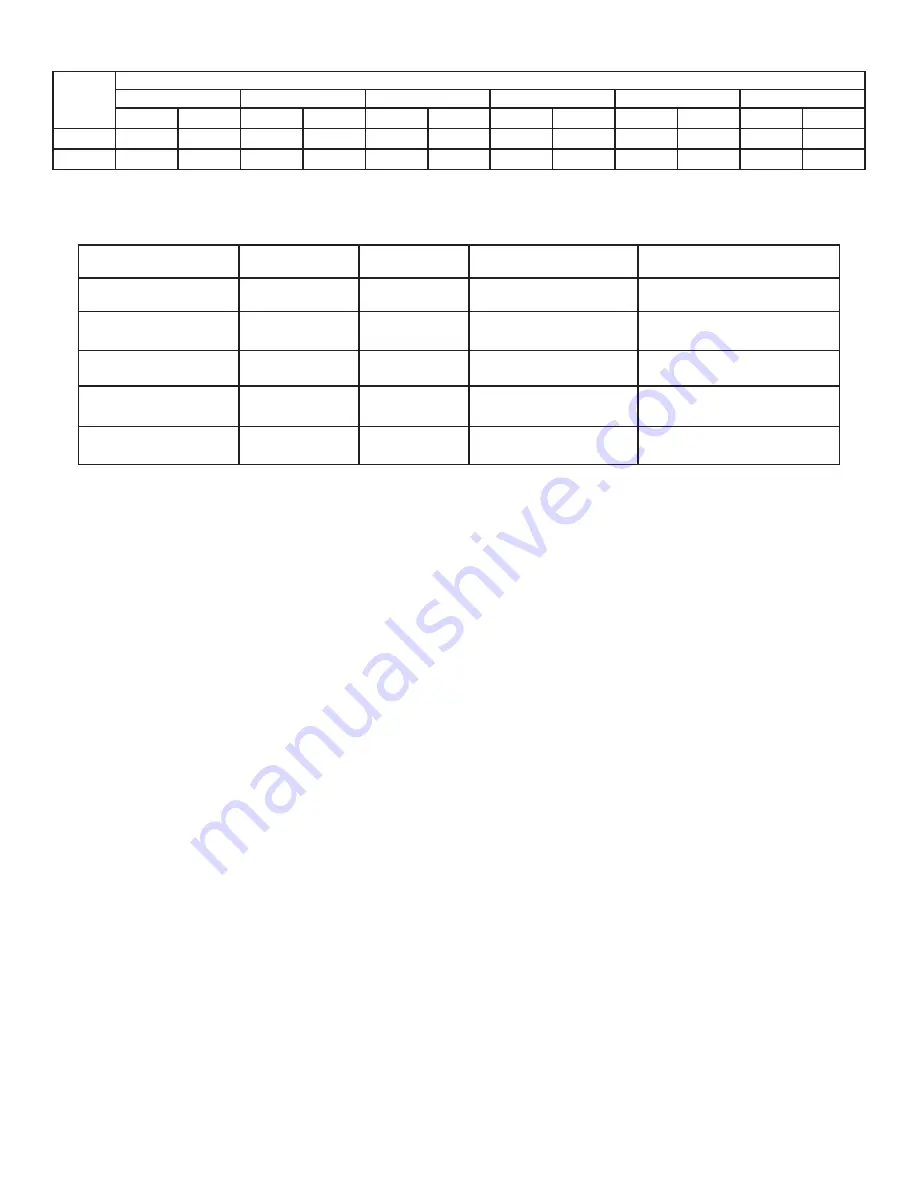

Table 1 - Approximate Lubricant Amount

Type

Mounting Position

A1

A2

A3

A4

A5

A6

Pints

Liters

Pints

Liters

Pints

Liters

Pints

Liters

Pints

Liters

Pints

Liters

BU383

1.6

0.8

3.2

1.5

3.2

1.5

3.9

1.9

3.0

1.9

3.3

1.6

BU483

2.1

1.0

5.1

2.4

5.1

2.4

5.9

2.8

4.6

2.2

5.1

2.4

The list below shows lubricants that are available as factory fill in QUANTIS reducers. The standard factory fill lubricant is Chevron FM

460, which is a high performance mineral oil lubricant with special additives for use in industrial gear products.

Table 2 - Lubricant Selection Table

Ambient

Temperature*

Oil Type

ISO

Viscosity Grade

Available Oils

Available Food Grade Oils (NSF H1)

45°F to 105°F

(7°C to 41°C)

Mineral Oil

460

-

Chevron FM 460

10°F to 105°F

(-12°C to 41°C)

Mineral Oil

220

Mobilgear 600 XP 220

(standard factory fill **)

-

-20°F to 50°F

(-29°C to 13°C)

Synthetic Oil

68

Mobil SHC 626

-

-10°F to 115°F

(-23°C to 46°C)

Synthetic Oil

220

Mobil SHC 630

-

30°F to 140°F

(-0° C to 60° C)

Synthetic Oil

460

Mobil SHC 634

-

*

Ambient temperatures listed are for lubricant only and do not indicate a particular gear unit’s suitability to run in that ambient.

**

Previous factory fill oil was Mobilgear 630 - Mobilgear 600 XP 220 and Mobilgear 630 are compatible with each other and do not

require a flush.

Recommendations will be made based on specific application details.