4

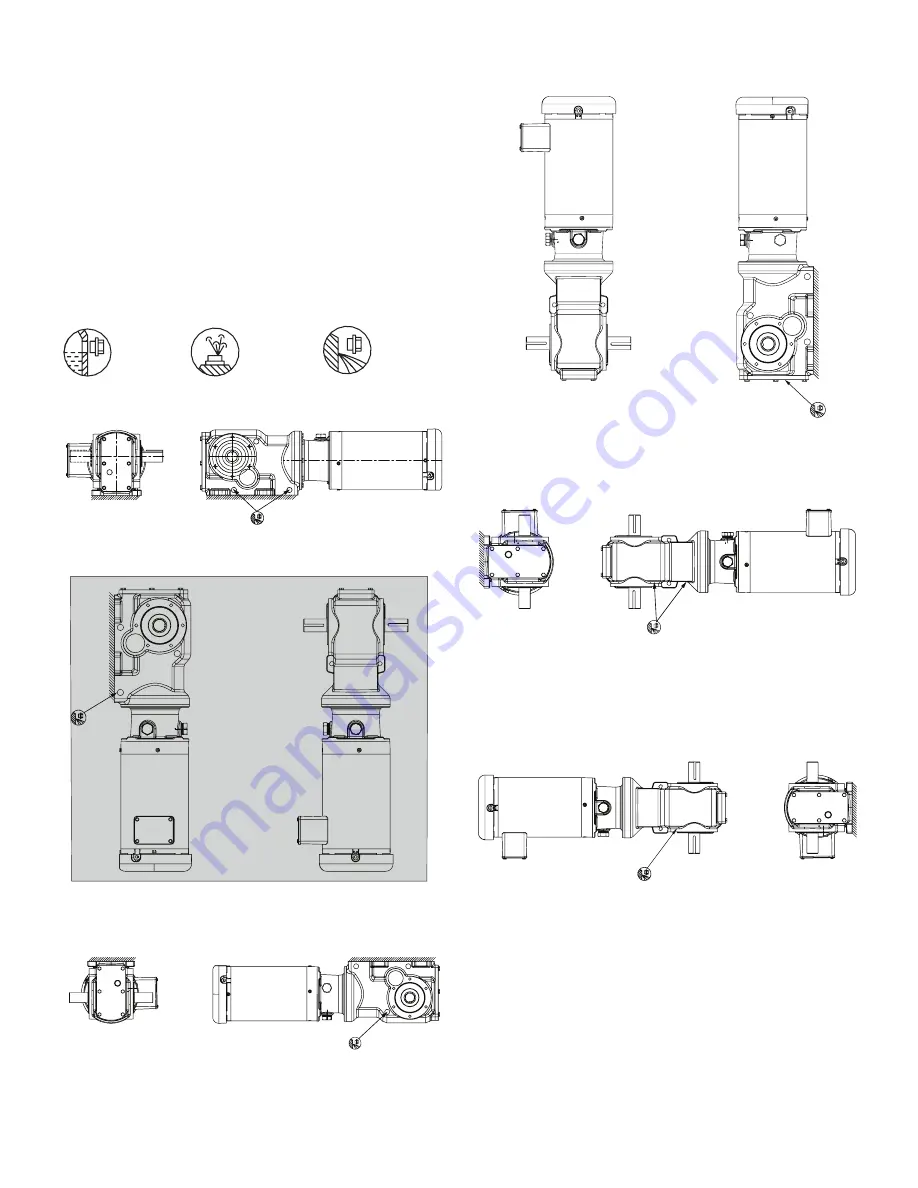

Mounting Position Diagrams

Quantis UK RHB Reducer

These mounting arrangements are for all output configurations

and output shaft types.

IMPORTANT! When ordering, please specify mounting position

for correct oil quantity. In cases of mounting position other than

shown here with regard to the oil quantity, please reference the

Incline Mounting page in the Quantis Engineering Catalog, and

contact Application Engineering.

NOTE: The oil volumes shown are approximate values

and cannot be used to correctly set the reducer oil level

- ALWAYS fill the reducer to the correct oil level plug and

recheck in 1 week.

Oil Level

Ventilation

Oil Drain

A1 - Horizontal - Floor Mount

A

B

A2 -Vertical Wall Mount - Motor Shaft Up

B

A

NOTE: Shaded A2 mounting is not a recommended mounting position due to

the weight of oil on the highspeed input seal.

A3 - Horizontal - Ceiling Mount

B

A

A4 - Vertical Wall Mount - Motor Shaft

Down

A

B

A5 - Horizontal - Wall Mount

B

A

A6 - Horizontal - Wall Mount

A

B