5

Long Term Storage

NOTE: Unless an extended warranty has been negotiated

prior to sale, time in storage is considered time in service

for warranty purposes.

If the drive is not installed immediately, it should be stored in a

clean, dry, protected area. During periods of long term storage

(six months or longer) special procedures must be followed. The

unit should be filled to the highest oil level hole with an approved

lubricant blended with 2%, by volume, of “Daubert Chemical Co.

Nox-Rust VCI-105” oil. Apply a thick coating of rust preventative

on all unpainted surfaces including threads, bores, keyways,

and shafts. Apply a thick coating of chassis-type grease to all

exposed shaft seals. If the unit is to be stored outdoors or in

a damp, unheated area indoors, cover the entire exterior with

a rust preventative. Seal the unit in a moisture proof container

or wrapping with a desiccant inside. Shade the enclosure from

direct sunlight. Rotate the input shaft at least 60 revolutions once

a month to redistribute the lubricant and prevent brinnelling of

bearings and drying of seals.

Upon removal from storage, remove all protective coatings applied

for protection during storage. Check all hardware for proper

tightness. Drain and refill the gear reducer with a recommended

lubricant. If the gear reducer has been stored for more than three

years or in an area with high ambient temperatures, replace the

oil seals.

Installation and Operation

Dodge Quantis UK RHB Reducers are shipped with filling, oil

level and drain plugs in place. Add or drain oil to get to the correct

oil level for the mounting position used.

Review the dataplates on the reducer and drive motor to verify

that the drive is correct for the intended loads, speeds and power

supply. The gear reducer should be installed in a location that

meets the following requirements:

•

Ambient temperatures below 105°F (41°C).

•

Free flow of air around the motor.

•

Good access to gear reducer and motor for maintenance.

•

A flat, level, rigid steel mounting surface.

•

All four feet of the foot-mounted unit must be evenly

supported.

•

The flange mounted unit must have even support at the

flange face.

•

Units supported by both flange and feet must be shimmed

to avoid housing stress.

•

Good alignment to both input and output devices.

Installation of Components on Gear Reducer

Shafts

Use care when installing couplings, sprockets and sheaves

(pulleys) on the Dodge Quantis UK RHB input and output shafts.

Such components should not be hammered into place. Damage

to shafts and bearings may result. If parts do not slip into place

easily, check for dirt or burrs that may be binding the assembly.

Very tightly fitted parts may need to be heated to get them onto

the shafts. Keys should be located for maximum engagement

between the shaft and the associated part. Sprockets and

sheaves should be mounted as close to the gearcase as possible

to minimize overhung loads. Retaining hardware (setscrews,

etc.) for couplings, sprockets and sheaves should be tightened

as recommended by the component manufacturer. Chain and

belt drives must be aligned to run true. Tighten chains and

belts according to the chain or belt manufacturer’s instructions.

Excessive tension results in rapid chain and belt wear and

reduces the bearing life of the Dodge Quantis RHB unit.

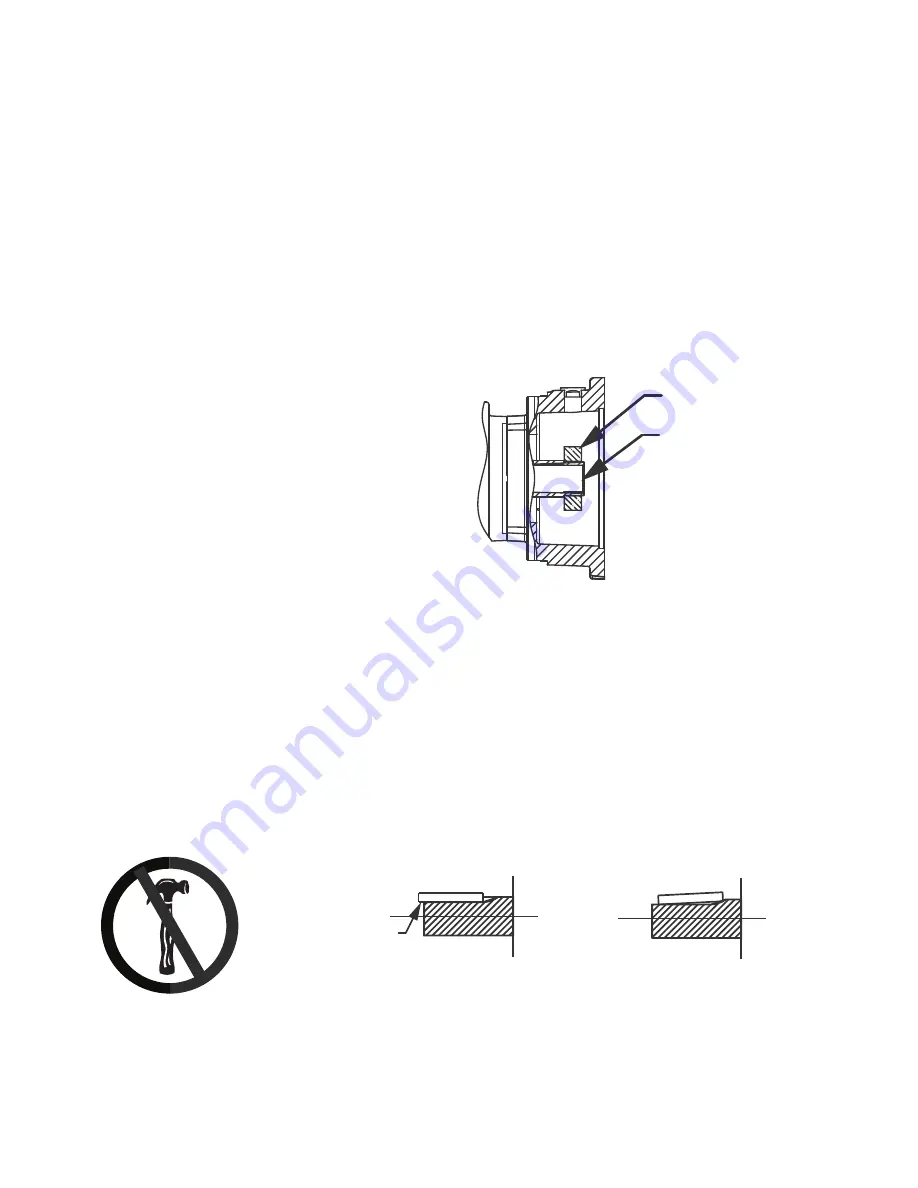

2 Reducer Input Bore

1 Clamp Collar

Figure 4 - Clamp Collar Assembly

Bottom of Key

Correct key fit in Motor Keyway

Incorrect key fit in Motor Keyway

Figure 5 - Clamp Collar Motor Key Fit