—

ABB Motors and Mechanical Inc.

5711 R. S. Boreham Jr. Street

Fort Smith, AR 72901

Ph: 1.479.646.4711

Mechanical Power Transmission Support

Ph: 1.864.297.4800

new.abb.com/mechanical-power-transmission

baldor.com

All Rights Reserved. Printed in USA.

10/19

© ABB Motors and Mechanical Inc.

MN16022

*16022-1019*

VB

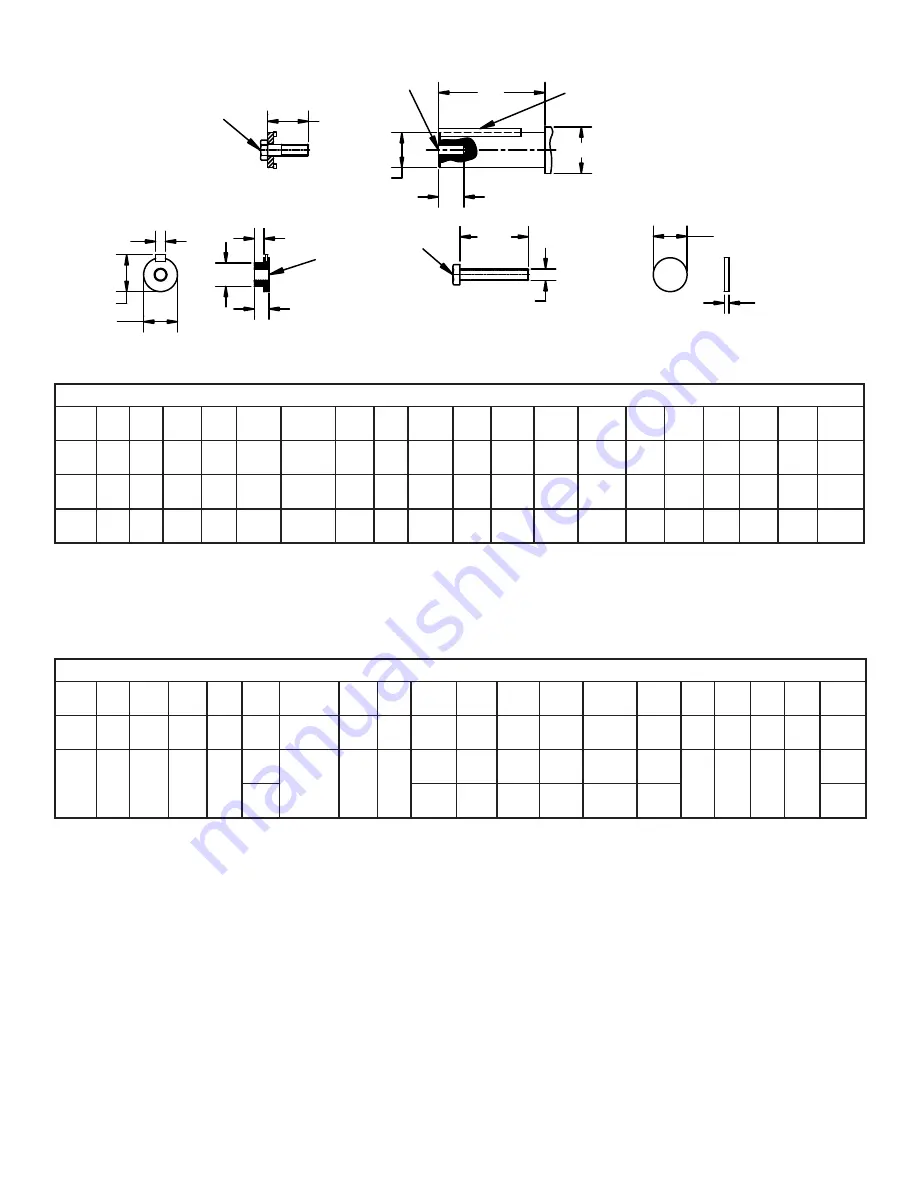

RETAINING BOLT M

ROUND KEYED NUT

UY

Y

x

UE

FG

x

FH

FV

M1-TAP

REMOVAL BOLT

M1

VB1

S

DISK

x

UE

GF

MACHINE'S

DRIVE SHAFT

VL

x

UG

M-TAP

2.5 x M

MINIMUM

CUSTOMER SUPPLIED KEY.

REFERENCE GEARCASE DIMENSIONS

FOR RECOMMENDED KEY.

x

RS

Straight Hollow Bore Assembly / Disassembly

Table 5 - INCH SHAFTS for Straight Hollow Bore Installation Dimensions - Inch

Unit

Size

FG

Ø

FH

FV

GF

M

M1

M4

S

Ø U

Y Max.

Ø

UE

Ø

UG

tol.

UY Max

VL

VB

VB1

VG

Ø RS

②

B_38

0.38 0.75 0.625

0.12

3/8-16

3/8-16

1.73

0.31

1.250

0.250

1.245

1.250

+0.000

-0.0006 1.367

3.50

1.75

6.00

4.02

1.75

B_48

0.38 0.93 0.625

0.12

3/8-16

5/8-18

2.28

0.50

1.375

0.312

1.370

1.375

+0.000

-0.0006

1.52

4.50

1.75

7.00

5.04

1.875

B_48

0.38 0.75 0.625

0.12

3/8-16

5/8-16

1.73

0.31

1.250

0.250

1.245

1.250

+0.000

-0.0006 1.367

4.50

1.75

7.00

5.04

1.75

Hollow shaft tolerances (For dimension U) are shown in the gearbox dimension pages.

Tolerance for dimension UE should be -0.01 in for inch bore shafts

Bold shaft diameters indicate standard shaft

②

RS Dimension is the minimum recommended shaft shoulder diameter

Straight Hollow Bore Assembly / Disassembly

Table 6 - METRIC SHAFTS for Straight Hollow Bore Installation Dimensions - millimeters

Unit

Size

FG

Ø FH

FV

GF

M

M1

M4

S

Ø U

Y Max.

Ø UE

Ø UG

tol.

UY Max

VL

VB

VB1

VG

Ø RS

②

B_38

10

9

15

6

M10

M10 x 1.5

44

8

30

8

29.9

30

+0.000

-0.013

33

90

40

150

102

42

B_48

9

22

15

6

M12

M12 x 1.5

58

10

35

10

34.9

35

+0.0000

-0.0016

38

115

60

180

128

47

M16

40

12

39.9

40

+0.0000

-0.0016

43

52

Hollow shaft tolerances (For dimension U) are shown in the gearbox dimension pages.

Tolerance for dimension UE should be -0.02 mm for metric bore shafts.

Bold shaft diameters indicate standard shaft

②

RS Dimension is the minimum recommended shaft shoulder diameter