3

Table 1 - Oil Volume

③

Reducer

Size

Volume of Oil Required to Fill Reducer to Oil Level Plug

➀

Position A

➀

Position B

➀

Position C

➀

Position D

➀

Position E

➀

Position F

Fluid

Ounces

(Approx)

Quarts

➁

(Approx)

Liters

(Approx)

Fluid

Ounces

(Approx)

Quarts

➁

(Approx

)

Liters

(Approx)

Fluid

Ounces

(Approx)

Quarts

➁

(Approx)

Liters

(Approx)

Fluid

Ounces

(Approx)

Quarts

➁

(Approx)

Liters

(Approx)

Fluid

Ounces

(Approx)

Quarts

➁

(Approx)

Liters

(Approx)

Fluid

Ounces

(Approx)

Quarts

➁

(Approx)

Liters

(Approx)

TXT105

20

5/8

.59

24

3/4

.71

20

5/8

.59

24

3/4

.71

36

1-1/8

1.06

44

1-3/8

1.30

TXT205

24

3/4

.71

28

7/8

.83

28

7/8

.83

28

7/8

.83

56

1-3/4

1.66

72

2-1/4

2.13

➀

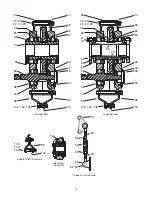

Refer to Figure 1 on page 2 for mounting positions

➁

U.S. Measure: 1 quart = 32 fluid ounces = .04646 liters

③

Below 15 RPM output speed, oil level must be adjusted

NOTE: If reducer position is to vary from those shown in Figure 1 either more or less oil may be required. Consult Dodge Product Support.

Table 2 -Lubrication Recommendations -ISO Grades

①

Output

RPM

For Ambient Temperatures of 50° thru 125°

Reducer Size

1

2

3

4

5

6

7

8

9

10

12

13

14

15

301-400

320

320

220

220

220

220

220

220

220

220

220

220

220

220

201-300

320

320

220

220

220

220

220

220

220

220

220

220

220

220

151-200

320

320

220

220

220

220

220

220

220

220

220

220

220

220

126-150

320

320

320

220

220

220

220

220

220

220

220

220

220

220

101-125

320

320

320

320

220

220

220

220

220

220

220

220

220

220

81-100

320

320

320

320

320

220

220

220

220

220

220

220

220

220

41-80

320

320

320

320

320

220

220

220

220

220

220

220

220

220

11-40

320

320

320

320

320

320

320

320

320

320

220

220

220

220

1-10

320

320

320

320

320

320

320

320

320

320

320

320

320

320

Output

RPM

For Ambient Temperatures of 15° thru 60°

Reducer Size

1

2

3

4

5

6

7

8

9

10

12

13

14

15

301-400

220

220

150

150

150

150

150

150

150

150

150

150

150

150

201-300

220

220

150

150

150

150

150

150

150

150

150

150

150

150

151-200

220

220

150

150

150

150

150

150

150

150

150

150

150

150

126-150

220

220

220

150

150

150

150

150

150

150

150

150

150

150

101-125

220

220

220

220

150

150

150

150

150

150

150

150

150

150

81-100

220

220

220

220

220

150

150

150

150

150

150

150

150

150

41-80

220

220

220

220

220

150

150

150

150

150

150

150

150

150

11-40

220

220

220

220

220

220

220

220

220

220

150

150

150

150

1-10

220

220

220

220

220

220

220

220

220

220

220

220

220

220

For reducers operating in ambient temperatures between -22°F (-30°C) and 20°F (-6.6°C), use a synthetic hydrocarbon lubricant. 100 ISO grade or AGMA 35 grade (lor

example - Mobil SHC627).

Above 125°F (51 .6°C), consult DODGE Gear Application Engineering (864) 288-9050 for lubrication recommendation.

NOTE: Pour point of lubricant selected should be at least 10'F lower than expected minimum ambient starting temperature. Refer to Viscosity Equivalency chart for lubricants

viscosity classification equivalents.

Special lubricants may be required for food and drug industry applications where contact with the product being manufactured may occur. Consult a lubrication manufacturers

representative for his recommendation.