1

WARNING: To ensure the drive is not unexpectedly

started, turn off and lock-out or tag power source before

proceeding. Failure to observe these precautions could

result in bodily injury.

WARNING: All products over 25 kg (55 lbs) are noted on the

shipping package. Proper lifting practices are required for

these products.

WARNING: Because of the possible danger to person(s)

or property from accidents which may result from the

improper use of products, it is important that correct

procedures be followed. Products must be used in

accordance with the engineering information specified

in the catalog. Proper installation, maintenance and

operation procedures must be observed. The instructions

in the instruction manuals must be followed. Inspections

should be made as necessary to assure safe operation

under prevailing conditions. Proper guards and other

suitable safety devices or procedures as may be desirable

or as may be specified in safety codes should be provided,

and are neither provided by ABB nor are the responsibility

of ABB. This unit and its associated equipment must be

installed, adjusted and maintained by qualified personnel

who are familiar with the construction and operation of

all equipment in the system and the potential hazards

involved. When risk to persons or property may be

involved, a holding device must be an integral part of the

driven equipment beyond the speed reducer output shaft.

DODGE

®

USN 500 and 600 Series Adapter Mount &

200 and 300 Series Direct Mount Plummer Blocks

These instructions must be read thoroughly before installation or operation. This instruction manual was accurate at the time of

printing. Please see

baldor.com

for updated instruction manuals.

Note! The manufacturer of these products, Baldor Electric Company, became ABB Motors and Mechanical Inc. on

March 1, 2018. Nameplates, Declaration of Conformity and other collateral material may contain the company name of

Baldor Electric Company and the brand names of Baldor-Dodge and Baldor-Reliance until such time as all materials have

been updated to reflect our new corporate identity.

GENERAL INFORMATION

Dodge USN bearings conform with all appropriate ISO

standards. They are available in either adapter or direct

mounting styles for 40 mm to 160 mm diameter shafts. A wide

variety of seals are available including standard metallic LER,

TRIPLE-TECT™ non-metallic seal with V-ring, Drop-in TRIPLE-

TECT seal with neoprene V-ring, Auxiliary Taconite or Split

non-metallic. TRIPLE-TECT seal is provided as standard on

complete assemblies. DODGE USN housings provide you with

maximum application flexibility. Cast-in dimples allow for easy

field modification for vents, lube ports and sensors. Oversized

drains and an oil equalization hole make USN bearings ready for

circulating oil systems off-the-shelf. For hostile environments,

USN offers optional cast closed end housings, stainless

steel hardware kits, and nickel or nylon coating. Complete

installation, maintenance and modification instructions are

provided in this manual.

INSPECTION

I

nspect shaft

— Ensure that the shaft is smooth, straight,

clean, and within commercial tolerances.

Inspect bearing

— Do not allow bearing to be exposed to any

dirt or moisture. Do not remove preservative compound as it

acts as both a protectant and lubricant and is also compatible

with standard greases.

Note: Housing caps and bases are not interchangeable.

They must be matched with mating half. Install non-

expansion bearing first.

Note: For seal types other than TRIPLE-TECT such as drop-

in TRIPLE-TECT, LER, auxiliary seals and split seals follow

instructions supplied with the seals.

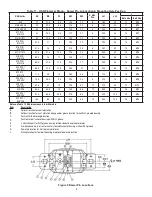

Note: For an explanation of the various dimples and tapped

holes found on the USN housings, see Table 11.

Summary of Contents for DODGE USN 500 Series

Page 15: ...15 ...