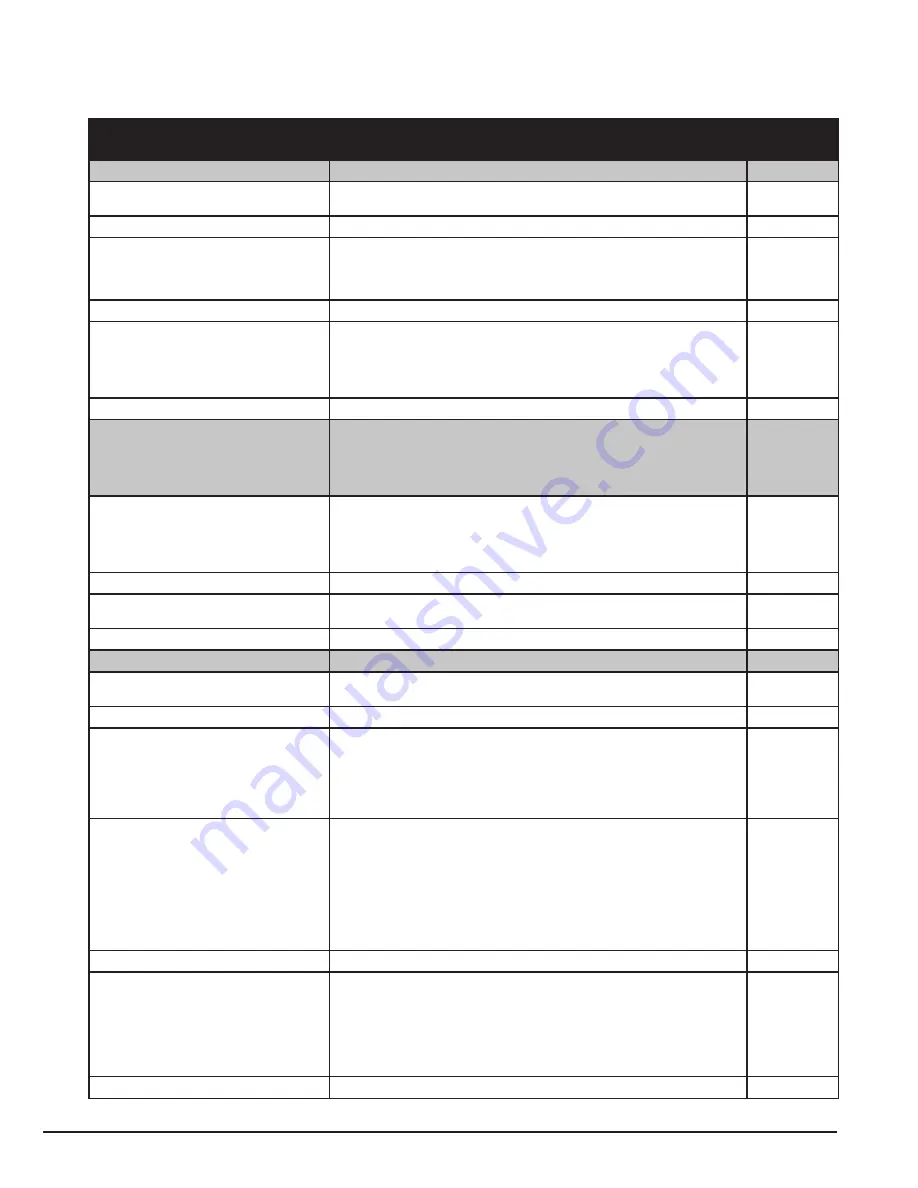

10-12 Parameter Definitions

MN448

Parameters in the Long parameter mode

No.

Name/Value

Description

Default

22

ACCEL/DECEL

Acceleration and deceleration times

2202

ACCELERATION RAMP TIME

Acceleration ramp time from 0 to base speed (Parameter

9907

MOTOR

RATED FREQUENCY) in seconds.

30.0 s

0.00…600.0 s

Time

2203

DECELERATION RAMP

TIME

Deceleration ramp time from base frequency (Parameter

9907

MOTOR

RATED FREQUENCY) to standstill in seconds.

When set to zero, fastest

possible ramp time without trip is activated.

When set to 0.00, the value of 2206 is used.

30.0 s

0.00…600.0 s

Time

2206

2nd DECELERATION

RAMP TIME (FAST STOP)

Parameter programs an alternative deceleration ramp down time for the

DRIVE, which can be selected by digital inputs (dependent on the setting

of Parameter 9902 DIGITAL INPUTS FUNCTION SELECT or selected

automatically in the case of a mains power loss if parameter 2102 STOP

MODE = 2.

0.00

0.00…600 s

When set to 0.00, the drive will coast to stop.

25

CRITICAL SPEEDS

Speed bands with which the drive is not allowed to operate.

The Skip Frequency function is used to avoid the DRIVE operating at

a certain output frequency, for example at a frequency which causes

mechanical resonance in a particular machine.

2500

SKIP FREQUENCY

HYSTERESIS BAND

The drive output frequency will ramp through the defined band at the rates

set in parameter

2202

and

2203

and will not hold any output frequency

within the defined band. If the frequency reference applied to the drive is

within the band, the drive output frequency will remain at the upper or lower

limit of the band.

0.0 Hz/RPM

0.0…

2008

2501

SKIP FREQUENCY

Defines the center point of the skip frequency band, and is used in

conjunction with parameter 2500 SKIP FREQUENCY HYSTERESIS BAND

0.0…2008

26

MOTOR CONTROL

Motor control variables

2601

ENERGY OPTIMIZER

Only active when enhanced V/F motor control mode is selected (parameter

9903 MOTOR CONTROL MODE = 2)

1

0 : DISABLED

1 : ENABLED

The Energy Optimizer attempts to reduce the overall energy consumed by

the drive and motor when operating at constant speeds and light loads.

The output voltage applied to the motor is reduced. The Energy Optimizer

is intended for applications where the drive may operate for some periods

of time with constant speed and light motor load, whether constant or

variable torque.

2603

V/F MODE VOLTAGE BOOST

Voltage boost is used to increase the applied motor voltage at low output

frequencies, in order to improve low speed and starting torque. Excessive

voltage boost levels may result in increased motor current and temperature,

and force ventilation of the motor may be required.

A suitable setting can usually be found by operating the motor under low

load or no load conditions at approximately 5Hz, and adjusting parameter

2603

until the motor current is no more than 80% of the rated full load

current.

3.0 %

0.0…25.0 %

2606

EFFECTIVE SWITCHING

FREQUENCY

Sets maximum effective switching frequency of the drive. If “

rEd

” is

displayed, the switching frequency has been reduced to the level in

Parameter 0417 INTERNAL EFFECTIVE SWITCHING FREQUENCY due to

excessive drive heat sink temperature.

Refer to parameter 0417 INTERNAL EFFECTIVE SWITCHING FREQUENCY

for further information regarding operation at higher switching frequency.

Drive Rating

Dependent

4…32 kHz

Summary of Contents for EC Titanium Series

Page 1: ... MN448_May 2020 May 2020 EC Titanium Manual User s guide ...

Page 10: ...1 4 Introduction MN448 ...

Page 20: ...3 4 Mechanical Information and Mounting MN448 ...

Page 26: ...4 6 Electrical Installation and Planning MN448 ...

Page 32: ...5 6 Control Pad Wiring and Keypad Interface MN448 ...

Page 36: ...6 4 Keypad Programming and Basic Operation MN448 ...

Page 44: ...8 4 Parameter Navigation and Groups MN448 ...

Page 51: ...9 7 Control Modes MN448 ...

Page 77: ...11 8 Standalone Motor and ABB Drive Setup MN448 ...

Page 99: ...A 12 Modbus RTU Example Connection MN448 ...

Page 102: ......