Standalone Motor and ABB Drive Setup 11-7

MN448

11.8 Speed Control Adjustment

Default tuning with the proportional gain (25.02) setting of 10 may result in unstable performance with EC Titanium motors.

Setting the proportional gain to 3 is recommended for smooth operation. Fine tuning the integration time is optional

depending on system dynamics.

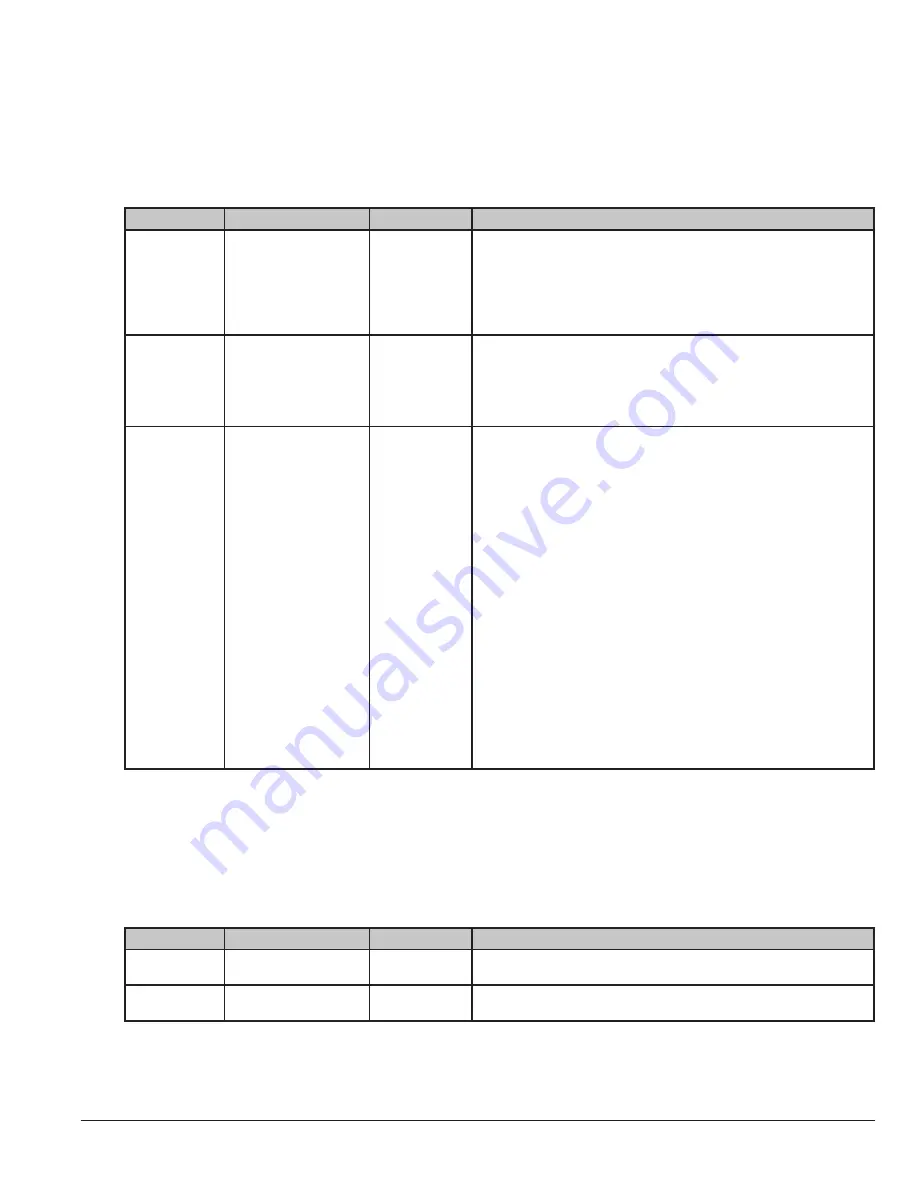

Parameter

Name

Value

Description

25.02

Speed Proportional

Gain

3

Defines the proportional gain (Kp) of the speed controller. Too

high a gain may cause speed oscillation.

Here set the proportional gain for the drive control to a value of

3.

Range: 0.00…250.00

25.03

Speed Integration

Time

2.5

Use if fine tuning of the motor performance is required, the

default setting of 2.50s is recommended for most applications.

Reference ACH580 firmware manual for advanced setup of the

speed integration time if required.

Range:0.00…1000.00 s

25.33

Speed controller

autotune

1

ON

Activates (or selects a source that activates) the speed controller

autotune function.

The autotune will automatically set parameters 25.02 Speed

proportional gain, 25.03 Speed integration time and 25.37

Mechanical time constant.

The prerequisites for performing the autotune routine are:

•

the motor identification run (ID run) has been successfully

completed

•

the speed and torque limits (parameter group 30 Limits)

have been set

•

speed feedback filtering (parameter group 90 Feedback

selection), speed error filtering (24 Speed reference

conditioning) and zero speed (21 Start/stop mode) have

been set, and the drive has been started and is running in

speed control mode.

WARNING: The motor and machinery will run against the

torque and speed limits during the autotune routine. MAKE

SURE IT IS SAFE TO ACTIVATE THE AUTOTUNE FUNCTION!

The autotune routine can be aborted by stopping the drive.

For better performance, auto-tuning the speed controller if possible is recommended. Turn the speed controller auto-tune

to on. The load should be connected at this point and free and safe to rotate. During the normal ID run, the motor will rotate

and perform a Parameter 25.33 auto-tune function.

11.9 Auto-phasing configuration

Enter the service password in parameter 96.2 (170708). Auto-phasing current should be between 0.2 and 0.3 p.u. Auto-

phasing time introduces a start delay and with small motors 2 to 3 seconds will be enough to ensure a successful initial rotor

positioning. On larger frame motors 4 to 5 seconds may be required.

Parameter

Name

Value

Description

25.20

Auto-phasing current

0.25

Per unit auto-phasing current for rotor alignment prior to starting

the motor.

25.21

Auto-phasing time

3

Time in seconds auto-phase current is applied to motor for rotor

alignment prior to starting.

Summary of Contents for EC Titanium Series

Page 1: ... MN448_May 2020 May 2020 EC Titanium Manual User s guide ...

Page 10: ...1 4 Introduction MN448 ...

Page 20: ...3 4 Mechanical Information and Mounting MN448 ...

Page 26: ...4 6 Electrical Installation and Planning MN448 ...

Page 32: ...5 6 Control Pad Wiring and Keypad Interface MN448 ...

Page 36: ...6 4 Keypad Programming and Basic Operation MN448 ...

Page 44: ...8 4 Parameter Navigation and Groups MN448 ...

Page 51: ...9 7 Control Modes MN448 ...

Page 77: ...11 8 Standalone Motor and ABB Drive Setup MN448 ...

Page 99: ...A 12 Modbus RTU Example Connection MN448 ...

Page 102: ......